Digital pressure gauge

A digital pressure gauge and pressure sensor technology, applied in the direction of measuring force, fluid pressure measurement by changing ohmic resistance, measuring device, etc., can solve the problems of inability to accurately measure temperature, difficult to transplant to low power consumption, and large amount of calculation. , to achieve the effect of significant compensation effect, simple and reasonable structure, and low power consumption of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The objective of the present invention is to design a new type of digital pressure gauge that can accurately measure the true working temperature of the sensitive element in the piezoresistive sensor, thereby performing more accurate temperature compensation, and at the same time having a simple and efficient temperature compensation method And nonlinear compensation method, and use low-power microprocessor to realize the compensation method.

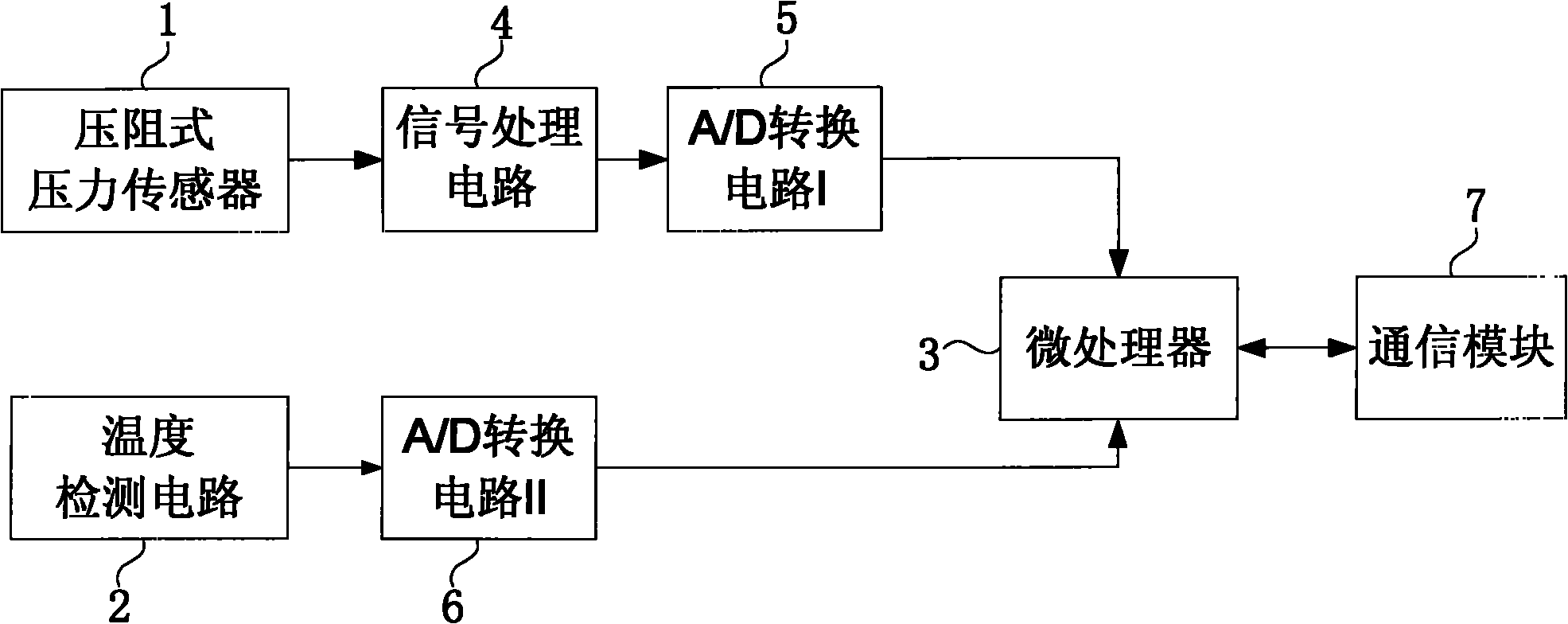

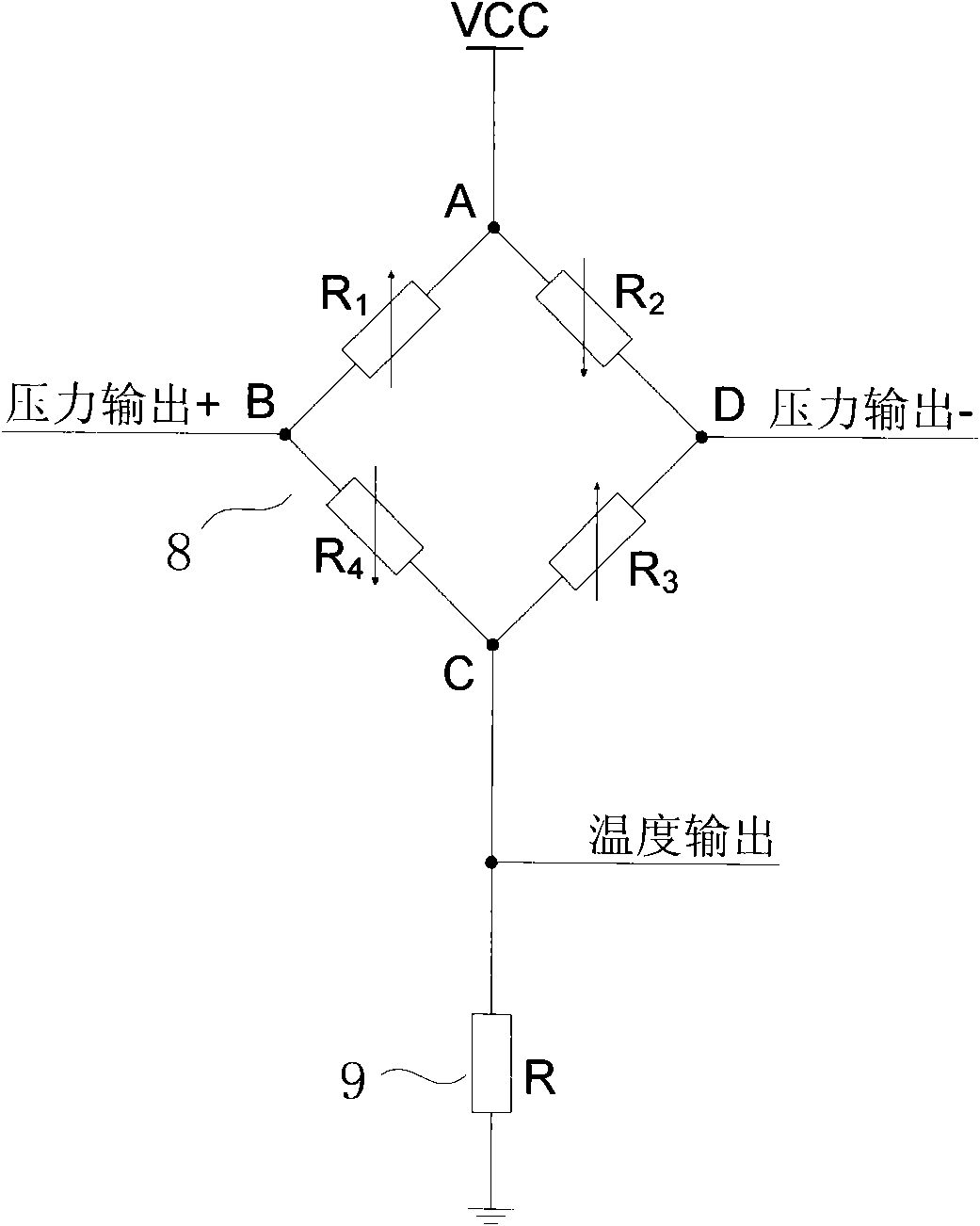

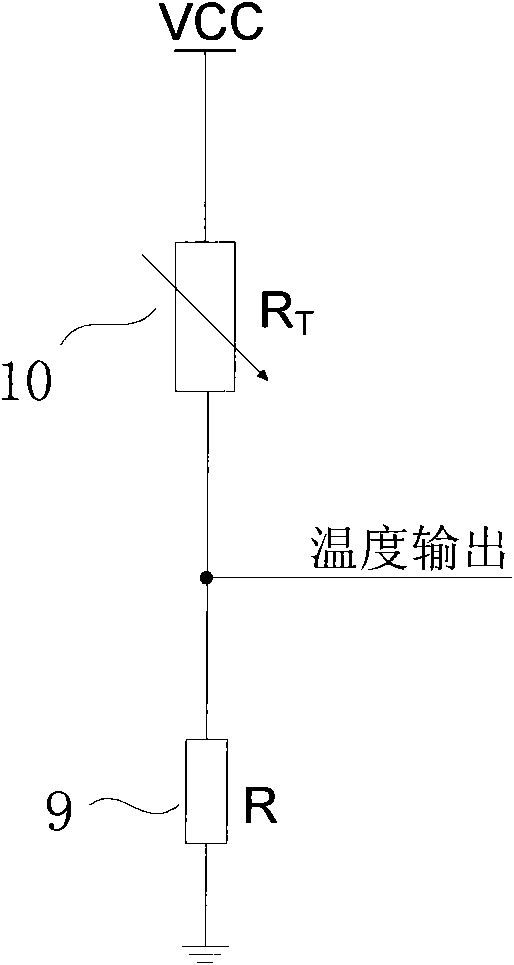

[0032] Refer to below figure 1 , figure 2 with image 3 The present invention will be described in detail, especially the temperature detection circuit can accurately measure the temperature of the pressure sensitive element. figure 1 It is a block diagram of the circuit principle of the present invention, which provides a digital pressure gauge. The digital pressure gauge includes: piezoresistive pressure sensor 1, signal processing circuit 4, A / D conversion circuit I 5, temperature measurement circuit 2, A / D conversion circuit I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com