Air-suspending T-shaped rail slider

An air suspension and rail technology, applied in the field of rail systems, can solve the problems of equipment accuracy decline, air gap changes, affecting measurement and machining accuracy, etc., and achieve the effect of avoiding force deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

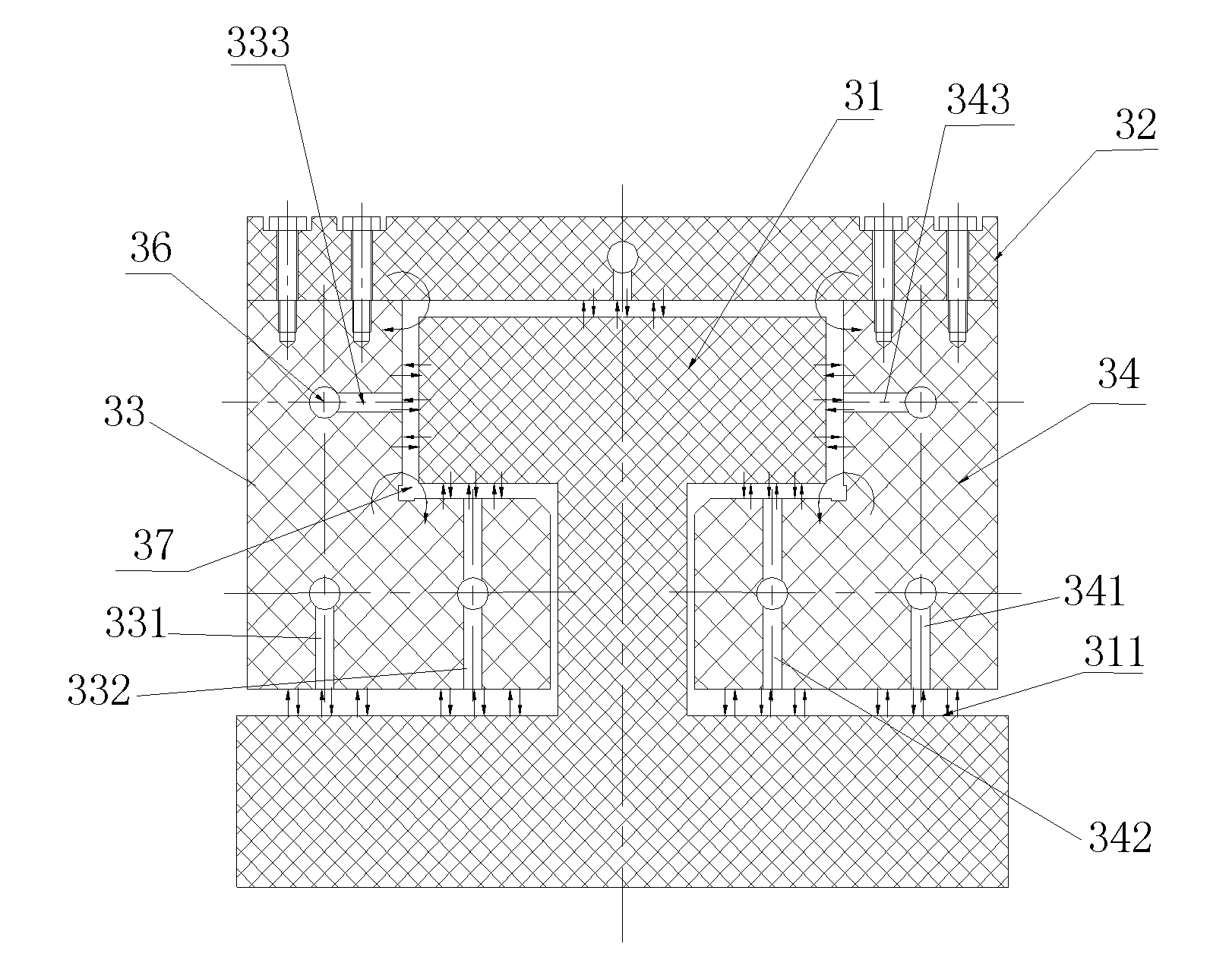

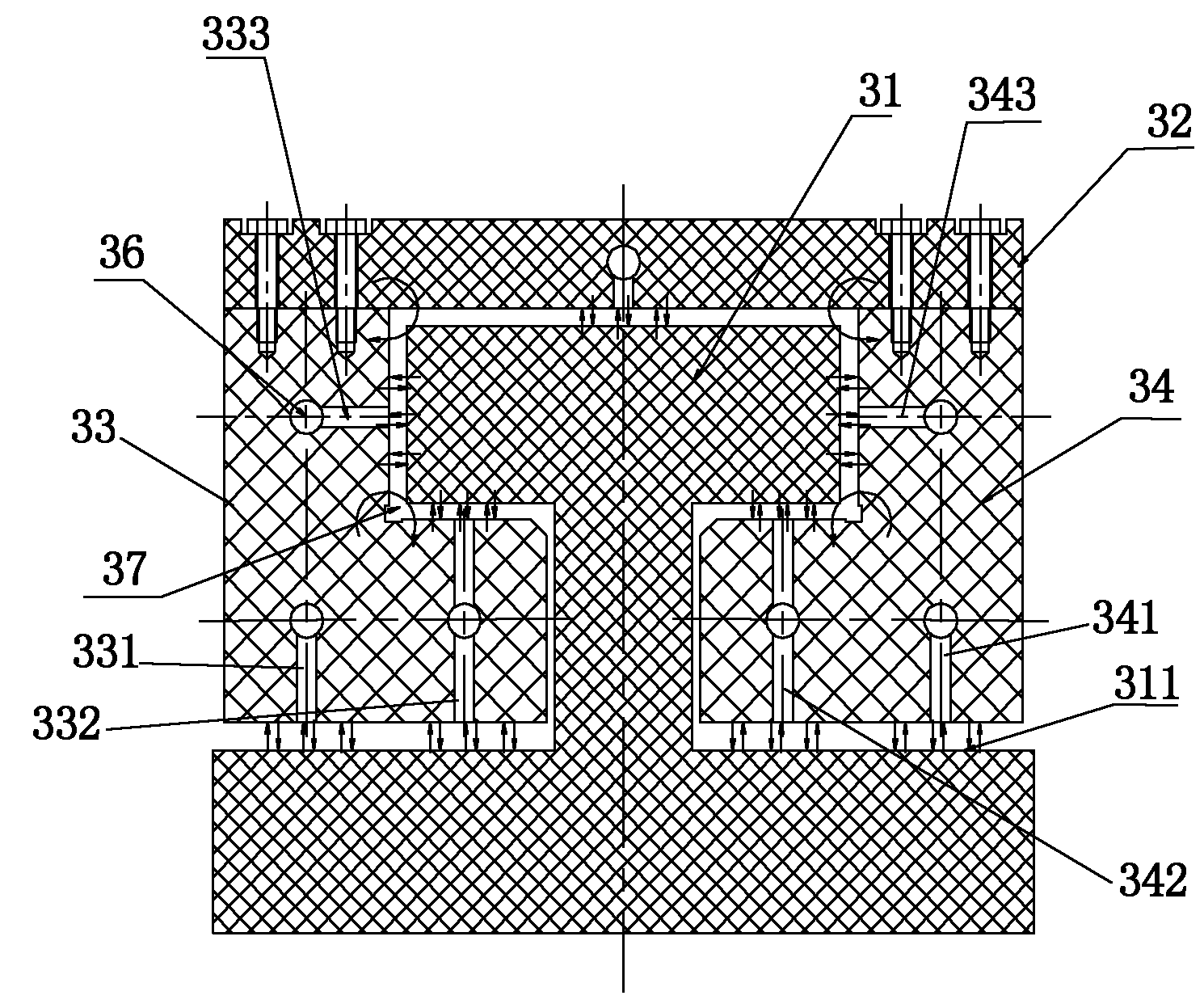

[0017] see figure 2 , the embodiment of the present invention is provided with upper panel 32, left panel 33 and right panel 34, and left panel 33 and right panel 34 are all L-shaped panels, and the lower side panel part of left panel 33 is provided with for blowing to guide rail base surface 311. The one-way air hole 331 and the two-way air hole 332 of air are provided with the one-way air hole 333 on the upper side panel part of the left panel 33; 341 and two-way air hole 342, the upper side panel part of right panel 34 is provided with one-way air hole 343. exist figure 2 Among them, mark 36 is the gas pipeline, and 37 is the gap between gas films.

[0018] The connection mode between the panels of the existing slider depends on the material and size, and is usually bolted or connected by other methods such as chemical agent gluing.

[0019] In the improved str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com