Porous polymer material with ultra-high specific surface area, preparation method thereof and use thereof in gas storage or liquid adsorption

A technology of ultra-high specific surface area and porous polymers, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems that the performance of organic porous polymer materials needs to be further improved, and achieve the effect of excellent hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

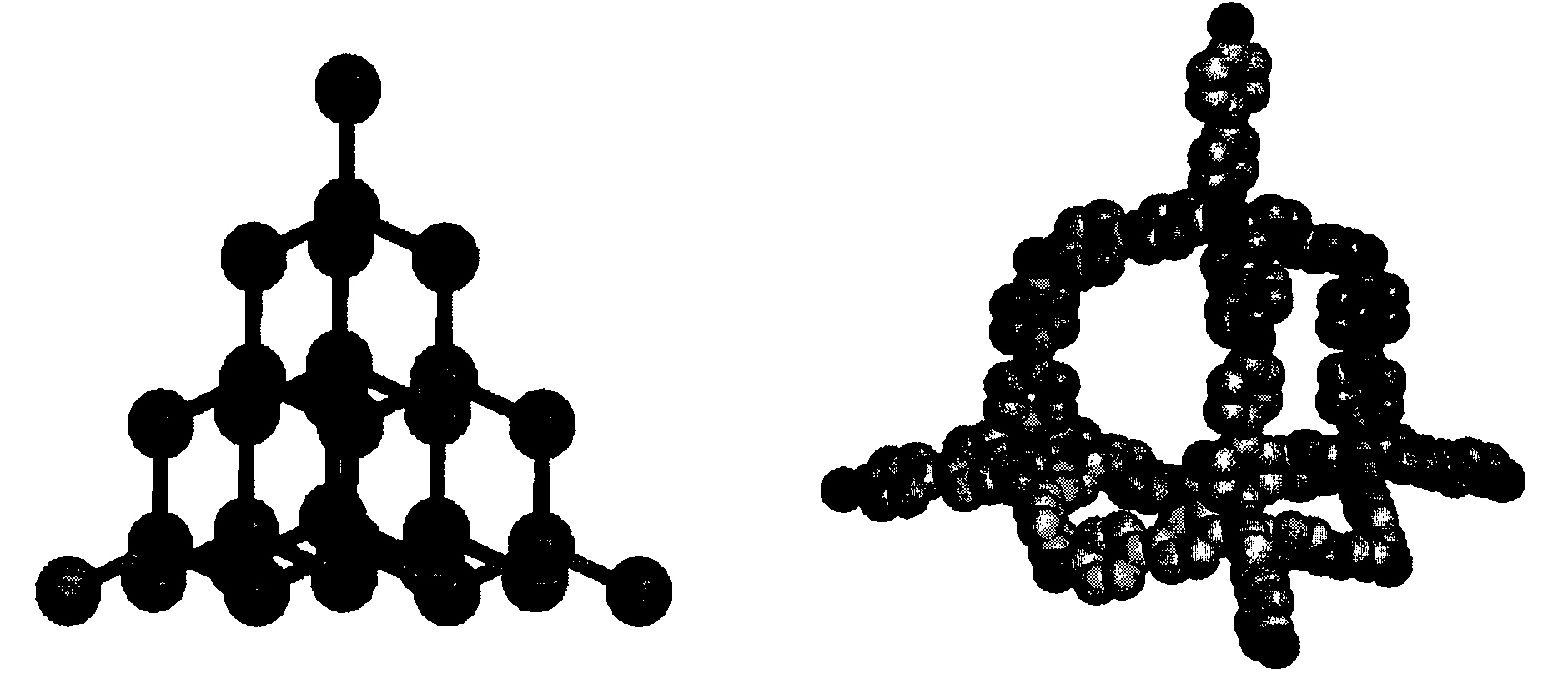

Image

Examples

preparation example Construction

[0053] The preparation method of the present invention has the porous polymer material of ultra-high specific surface area, comprises the following steps:

[0054] Step 1, adding bis-1,5-cyclooctadiene nickel, 2,2-bipyridine and 1,5-cyclooctadiene into N,N-dimethylformamide or toluene solution, Put it into an oil bath preheated to 20°C-140°C to age the catalyst for 0.5-3 hours;

[0055] Step 2, add the N,N-dimethylformamide or toluene solution of p-bromotetraphenylmethane or p-iodotetraphenylmethane corresponding to the number of moles, so that the concentration of the reactant remains between 0.001M-5M, while ensuring that the double The ratio of 1,5-cyclooctadiene nickel to halogen atoms is between 0.6-1.5;

[0056] Step 3, keeping the above solution at temperature, reacting for 10 minutes to 5 days, and stopping the reaction;

[0057] Step 4, adding concentrated hydrochloric acid to the reaction system to destroy the remaining double 1,5-cyclooctadiene nickel;

[0058] S...

Embodiment 1

[0078] (1) 1g of double 1,5-cyclooctadiene nickel, 0.568g 2,2-bipyridine and 0.4mL of 1,5-cyclooctadiene were added to 1mL of N,N-dimethylformamide solution, Put it into an oil bath preheated to 60°C to age the catalyst for 0.5-3 hours;

[0079] (2) Then 3 mL of 0.2 M p-bromotetraphenylmethane N, N-dimethylformamide, react at this temperature for 60 hours, and stop the reaction;

[0080] (3) Add concentrated hydrochloric acid in reaction system, destroy excessive 1,5-cyclooctadiene nickel, filter to obtain pale yellow precipitate;

[0081] (4) Wash with hot solutions of 100mL water, 100mL tetrahydrofuran and 100mL chloroform to remove inorganic salts and soluble organic matter;

[0082] (5) The final product was vacuum-dried at 80-200°C for 10-40 hours (vacuum degree less than 10-3 mmHg) to obtain a polymer with a yield of 76%.

[0083] As shown in Figure 2, it is the infrared contrast spectrogram of the porous polymer material and the reaction monomer prepared by p-bromotet...

Embodiment 2

[0096] The mixed solution in step (1) of Example 1 was moved to a stainless steel vacuum reactor, the reaction temperature was changed to 80° C., and the other conditions were unchanged, and the same material as described in Example 1 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com