Polarizing plate, optical member, and liquid crystal display device

A polarizing plate and polarizing film technology, which is applied in the field of optical components and liquid crystal display devices, can solve the problems of limited thinness and light weight, and achieve the effect of improving mechanical strength, hardness, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

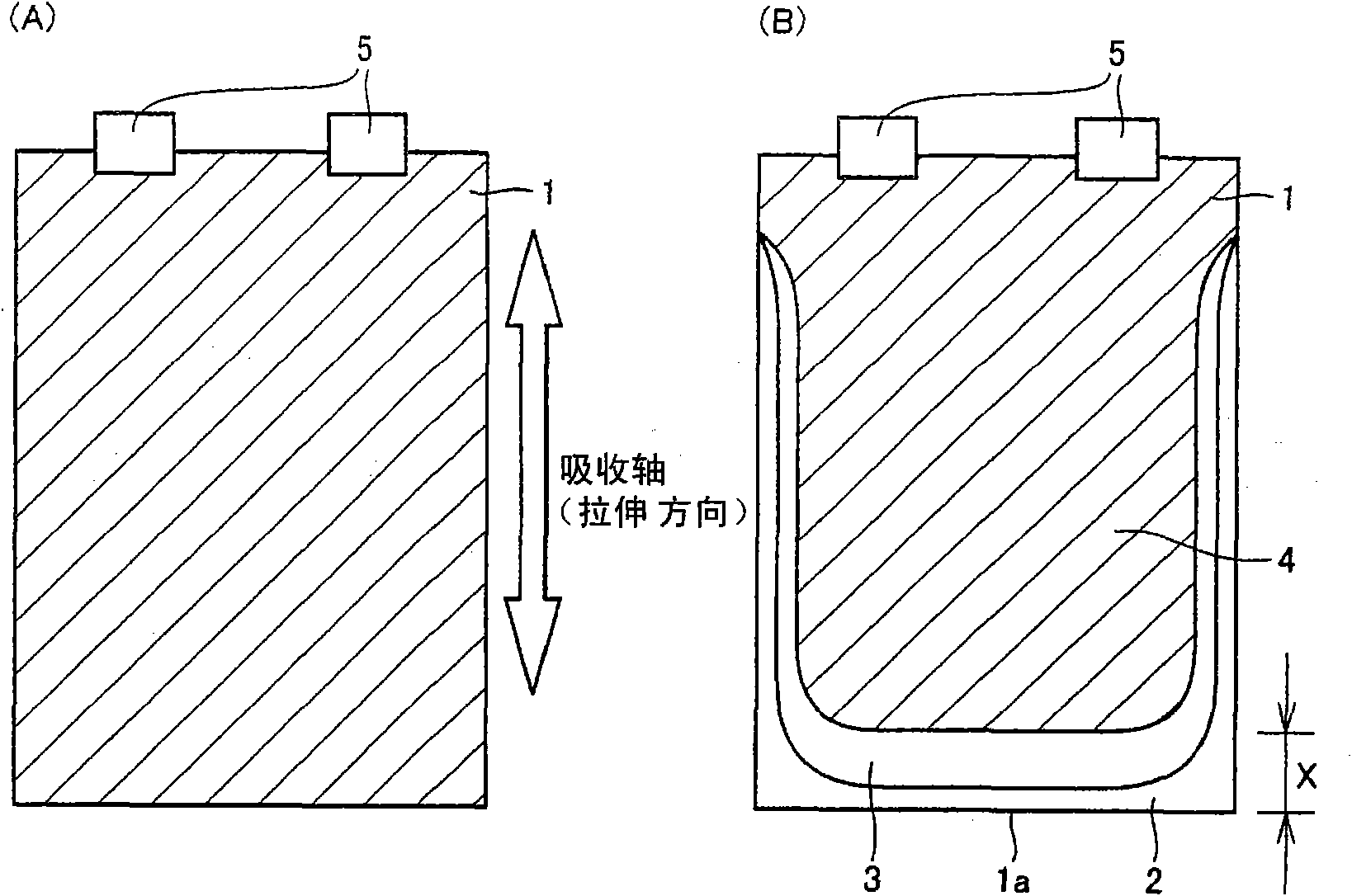

[0164] (Manufacturing example 1: Production of polarizing film)

[0165]After immersing a polyvinyl alcohol film with an average degree of polymerization of about 2400, a saponification degree of 99.9 mol% or more, and a thickness of 75 μm in pure water at 30°C, the weight ratio of iodine / potassium iodide / water at 30°C is 0.02 / 2 / 100 Dip in aqueous solution. After that, it was immersed in an aqueous solution having a weight ratio of potassium iodide / boric acid / water of 12 / 5 / 100 at 56.5°C. Next, after washing with 8° C. pure water, it was dried at 65° C. to obtain a polarizing film (thickness 30 μm) in which iodine was adsorbed on polyvinyl alcohol and iodine was oriented. Stretching is mainly carried out in the process of iodine dyeing and boric acid treatment, and the total stretching ratio is 5.3 times.

manufacture example 2

[0166] (Manufacturing Example 2: Preparation of Curable Resin Composition I)

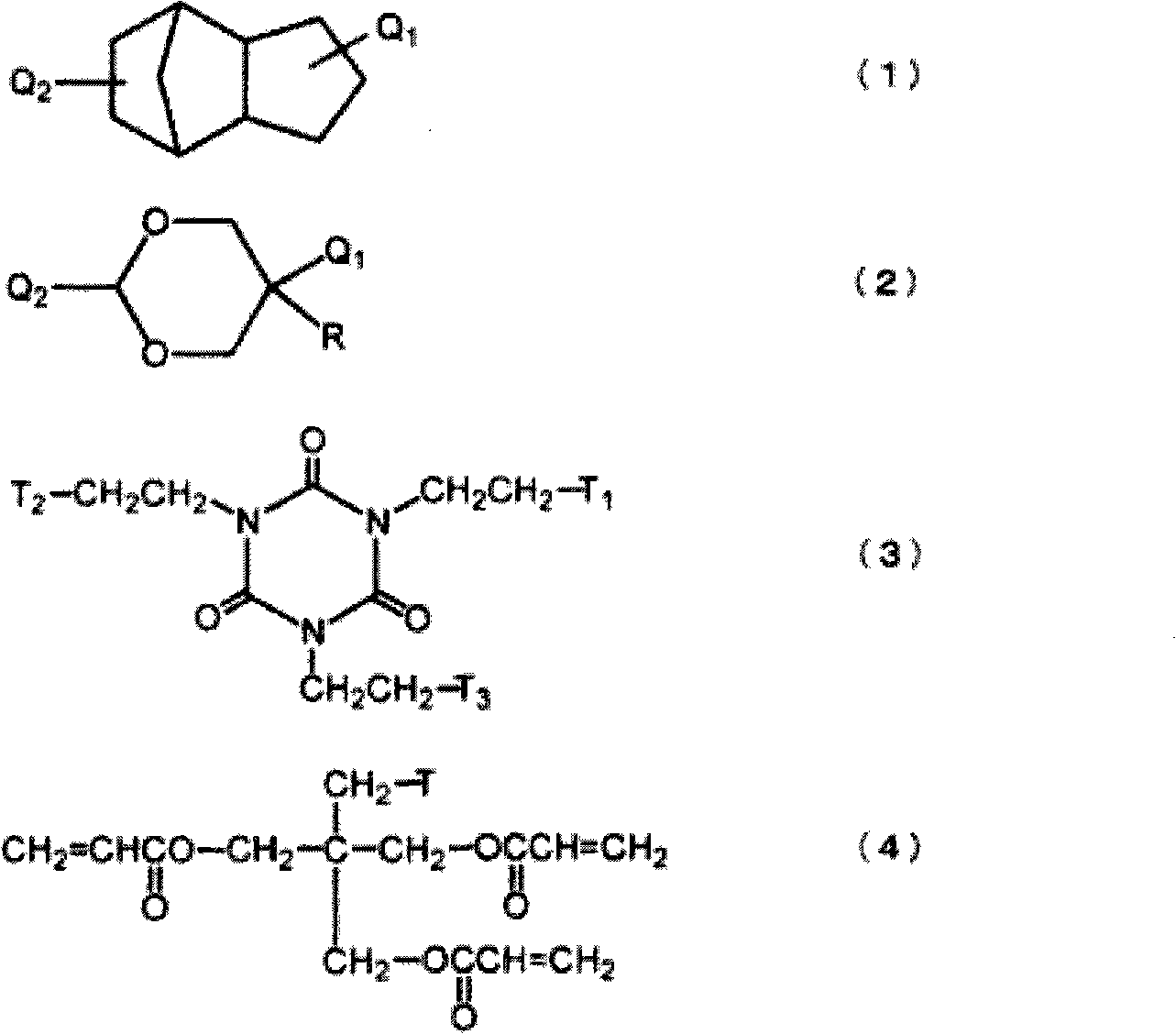

[0167] The following components were mixed to obtain curable resin composition I.

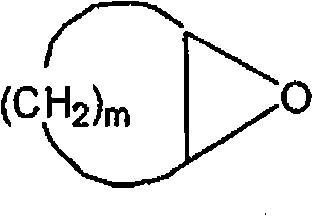

[0168] ◆3,4-epoxycyclohexylmethyl-3,4-epoxycyclohexanecarboxylate (manufactured by Daicel Chemical Co., Ltd., Ceroxide 2021P): 35 parts

[0169] ◆Bis(3-ethyl-3-oxetanylmethyl) ether (manufactured by Toagosei Co., Ltd., ARON OXETANE OXT-221): 15 parts

[0170] ◆Tricyclodecane dimethanol diacrylate (manufactured by Shin-Nakamura Chemical Co., Ltd., A-DCP): 50 parts

[0171] ◆2-Hydroxy-2-methyl-1-phenylpropan-1-one (manufactured by Ciba Specialty Chemicals Co., Ltd., DAROCURE 1173, radical polymerization photoinitiator): 2.5 parts

[0172] ◆4,4'-bis[diphenylsulfonium]diphenylsulfide bishexafluorophosphate cationic polymerization photoinitiator (Adeka Optomer SP-150 manufactured by Adeka): 2.5 parts

[0173] ◆Silicone-based leveling agent (manufactured by Dow Corning Toray, SH710): 0.2 parts

[0174] In addition, the...

manufacture example 3

[0176] (Manufacturing example 3: Preparation of curable resin composition II)

[0177] The following components were mixed to obtain curable resin composition II.

[0178] ◆3,4-epoxycyclohexylmethyl-3,4-epoxycyclohexanecarboxylate (manufactured by Daicel Chemical Co., Ltd., Ceroxide 2021P): 35 parts

[0179] ◆Bis(3-ethyl-3-oxetanylmethyl) ether (manufactured by Toagosei Co., Ltd., ARON OXETANE OXT-221): 15 parts

[0180] ◆Diacrylate ester of acetal compound of hydroxypivalaldehyde and trimethylolpropane (manufactured by Shin-Nakamura Chemical Industry Co., Ltd., A-DOG): 50 parts

[0181] ◆2-Hydroxy-2-methyl-1-phenylpropan-1-one (manufactured by Ciba Specialty Chemicals Co., Ltd., DAROCURE 1173, radical polymerization photoinitiator): 2.5 parts

[0182] ◆4,4'-bis[diphenylsulfonium]diphenylsulfide bishexafluorophosphate cationic polymerization photoinitiator (Adeka Optomer SP-150 manufactured by Adeka): 2.5 parts

[0183] ◆Silicone-based leveling agent (manufactured by Dow Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com