Method for determining content of pulverized coal, coke and iron-containing charge in blast furnace dust

A determination method and blast furnace technology are used in the determination of blast furnace dust composition and the determination of the content of pulverized coal, coke and iron-containing charge in blast furnace dust, and can solve the problem of large error in results, complicated operation, and inability to accurately reflect the composition. situation and other problems, to achieve the effect of high accuracy and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

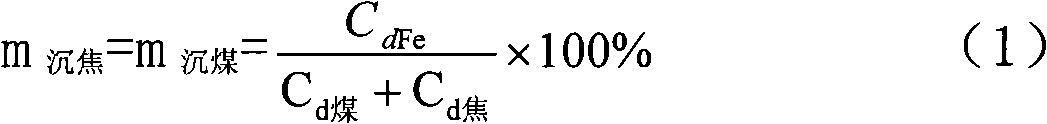

Method used

Image

Examples

Embodiment

[0027] Sampling of primary furnace dust, secondary furnace dust and coke, coal powder, sintered ore, pellets, lump ore, etc. in the blast furnace production site, dried and ground to a particle size of <0.125mm, and measured the true value of each raw material and fuel Density, the results are shown in Table 1:

[0028] Table 1 True density of raw material and fuel

[0029]

[0030] According to the difference in the true density of coal, coke and ironmaking raw materials, the density is 1.60g / cm 3 Zinc chloride ZnCl 2 The solution is the separation medium to separate the coal dust from the furnace dust. The centrifuge speed is 8000rpm, the centrifuge tube volume is 50ml, and the centrifugation time is 30min. The liquid level of the separation medium is 85% of the centrifuge tube height. The furnace dust in each centrifuge tube The ratio of the mass to the volume of the separation medium is 1:8, and the separation time is 30 minutes. After centrifugation, carefully pour out the up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com