Debugging method of dry-quenching automatic meter system

A technology of instrumentation system and debugging method, which is applied in the direction of equipment, coke oven, coke cooling, etc., can solve the problems of complicated, unreasonable and unscientific debugging process, and achieve the effect of simple debugging method and high operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

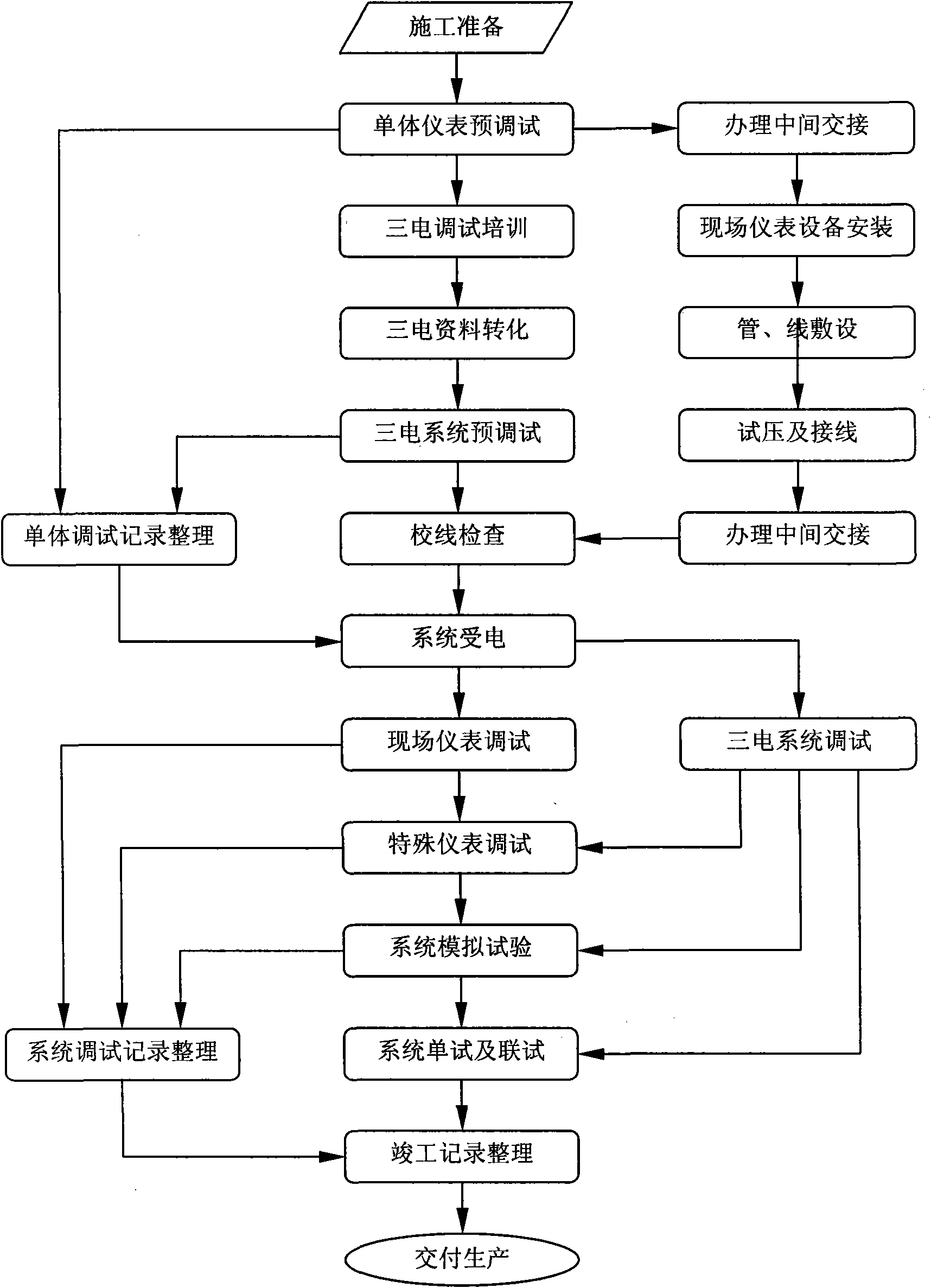

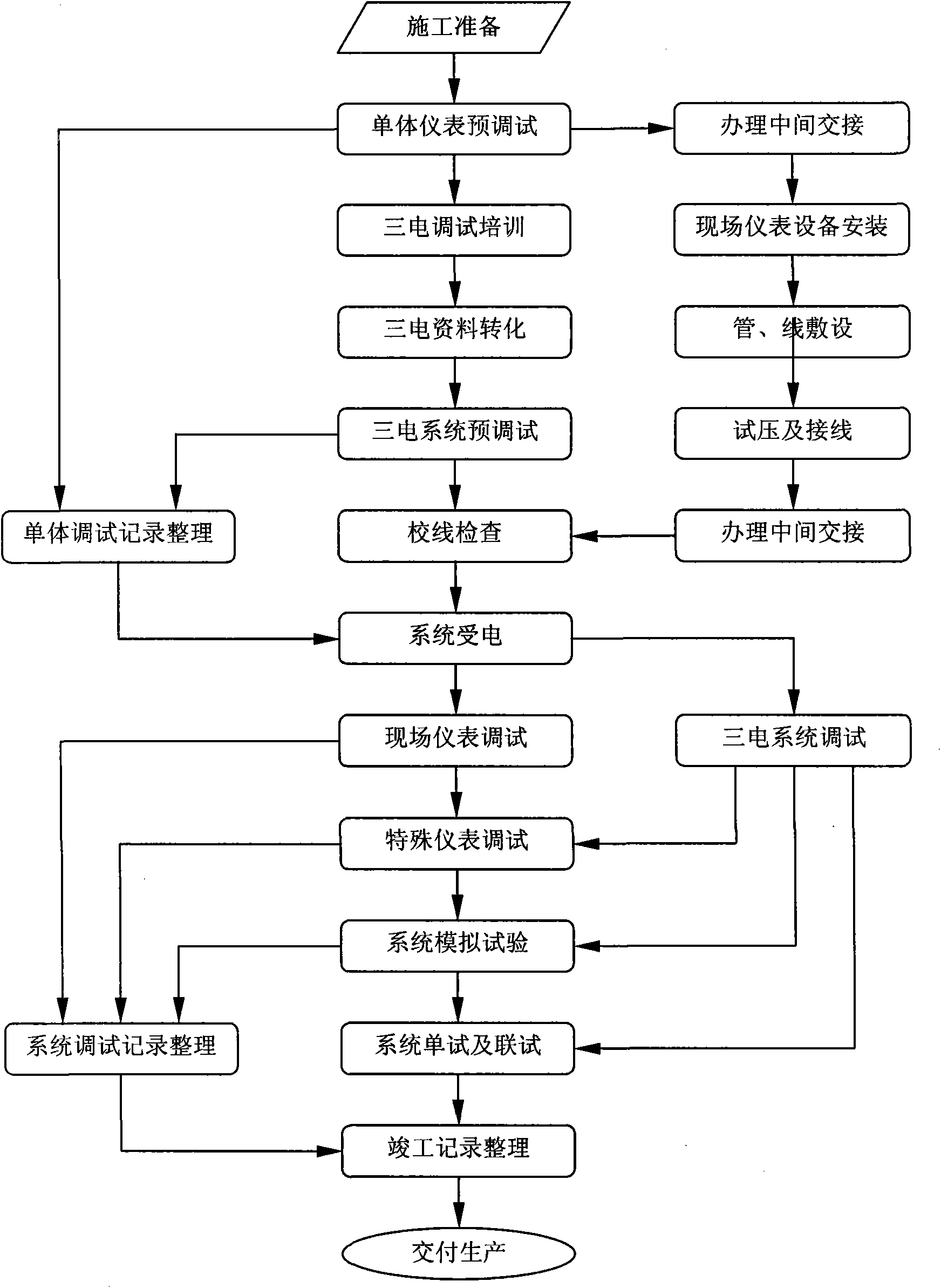

Image

Examples

Embodiment 1

[0014] A CDQ automatic instrumentation system debugging method, after the construction preparation is completed, the following steps are carried out in sequence: a. Debugging of conventional instruments, b. Debugging of special instruments, c. Detection test input and output components, d. Simulation test of instrumentation system, e. The instrument system cooperates with the joint test and f. The no-load linkage test run,

[0015] Complete the following construction preparations before commissioning:

[0016] 1. Technical preparation

[0017] (1) Before commissioning, the project leader must make a safety and technical disclosure to all commissioning personnel, clarify the scope and key points of commissioning, and explain the commissioning requirements.

[0018] (2) Familiar with the instrument construction drawings and related technical materials, and prepare various debugging record forms.

[0019] (3) Debugging personnel must hold an electrician operation certificate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com