Circular cooler air inlet system

A technology of air intake system and ring cooler, which is applied in mechanical equipment, engine components, engine sealing, etc., can solve the problems of temperature difference between the two sides of the spacer, difficulty in ensuring reliability, and limited strength, so as to ensure normal operation, The effect of preventing vaporization and speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

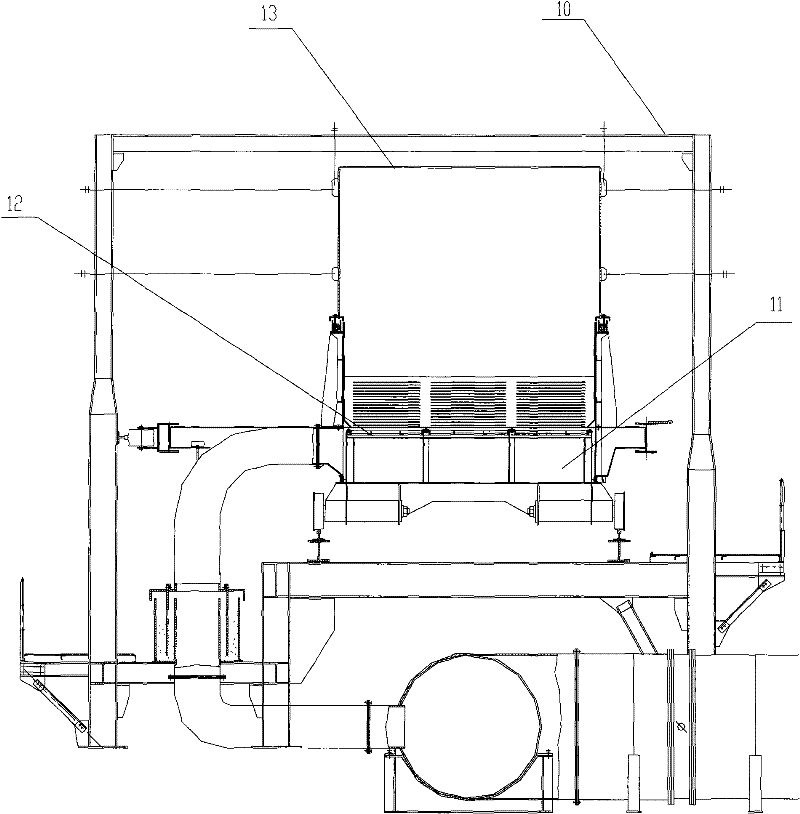

[0044]The invention provides an air intake system of a ring cooler, which can prevent the liquid in the annular liquid tank from vaporizing, and provide a power source for pushing the air flow in the double wall sleeve.

[0045] In order to facilitate the understanding of those skilled in the art, the structure and working principle of the air inlet system of the annular cooler according to the present invention will be described in detail below with reference to the accompanying drawings.

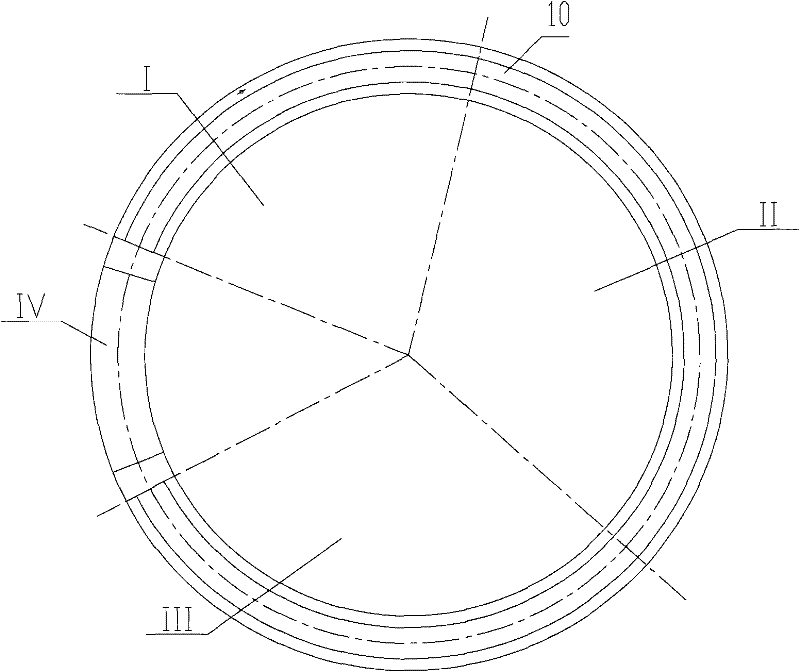

[0046] see Figure 4 , which is a structural diagram of the air intake system of the annular cooler according to the embodiment of the present invention.

[0047] The air inlet system of the annular cooler in the embodiment of the present invention includes an annular air duct 31, which is connected to a branch air duct 32 of the annular air duct 31, and the branch air duct 32 is connected to an annular air duct 33, and the annular air duct 33 Each outlet of each outlet is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com