Large-tonnage high-purity nitrogen equipment

A high-purity nitrogen, high-yield technology, applied in lighting and heating equipment, liquefaction, solidification, etc., can solve the problems of large floor area and high energy consumption, and achieve the goals of reduced floor space, simple process configuration, and material saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principle of the invention is to use the difference in the boiling points of oxygen and nitrogen in the air to produce high-purity nitrogen by means of low-temperature rectification.

[0024] Specific embodiments of the present invention will be described below with reference to the drawings.

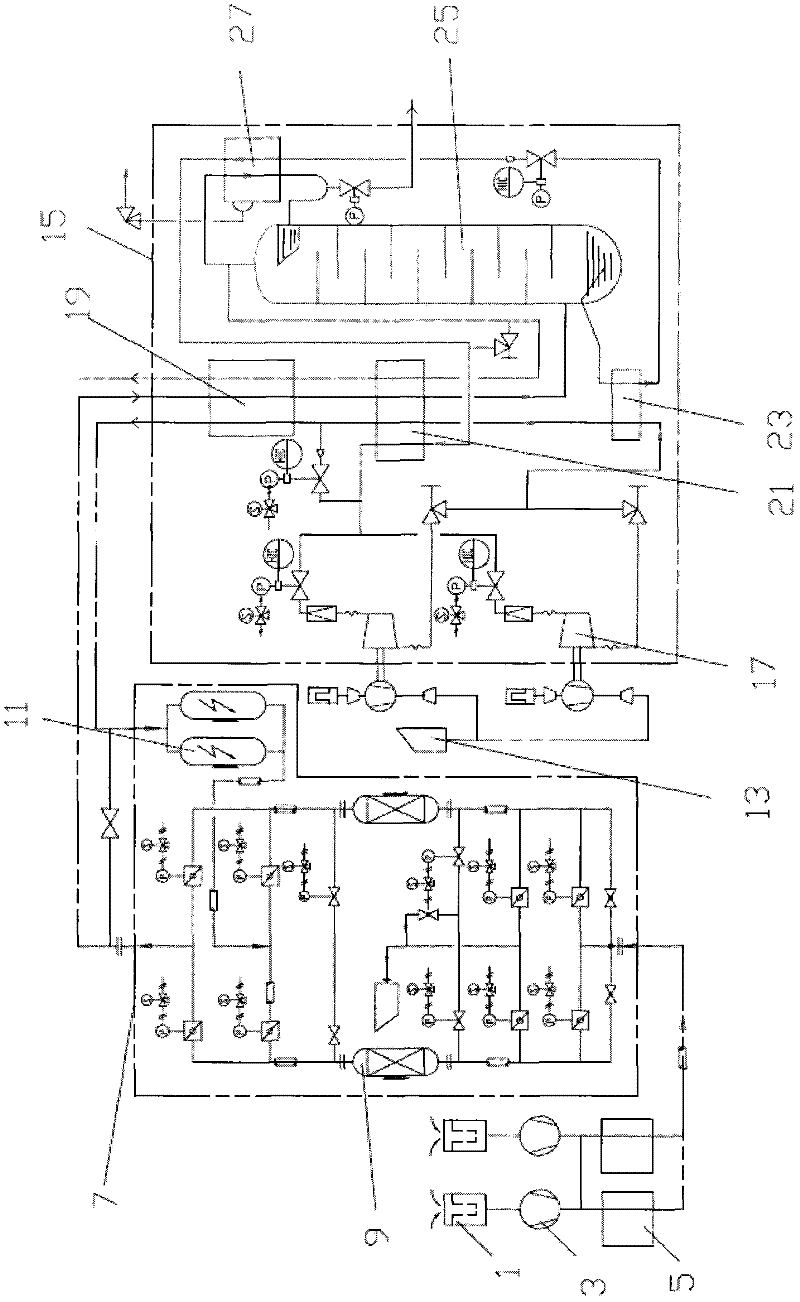

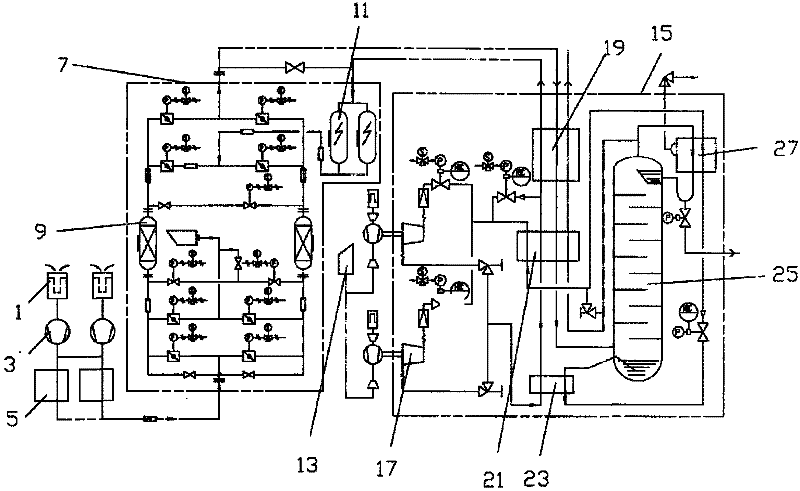

[0025] Such as figure 1 , the large-capacity high-purity nitrogen equipment of the present invention mainly includes a pretreatment system, a purification system 7 and a fractionation tower 15 interconnected by pipelines.

[0026] The pretreatment system includes a filter 1, an air compressor 3, and a precooler 5 interconnected by pipelines. The pre-cooler 5 adopts the Freon pre-cooling unit to cool the air to 5~10°C, and the condensed water is separated through the water separator, so as to reduce the load of the purification system, make the adsorption effect of the purification system better, and ensure the continuous safety of the equipment The requirement for the opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com