Premixed type combustion system for heat treatment of outer surface of plastic pipe and gas nozzle

A technology of combustion system and plastic pipe, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of non-adjustment, uneven temperature of ordinary nozzles, and achieve the effect of overcoming potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

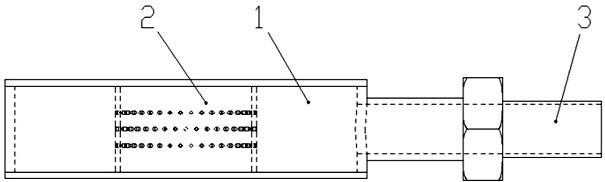

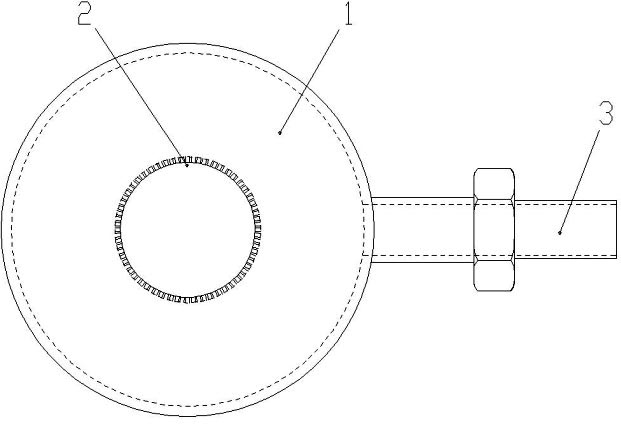

[0014] Such as figure 1 , as shown in 2, the gas nozzle includes a ring-shaped nozzle column, and an annular gas-air mixing nozzle 2 is arranged in the middle of the nozzle column, and three rows of holes are alternately arranged on the nozzle 2, and between the annular gas-air mixing nozzle 2 and the outer wall of the nozzle column A gas-air mixture chamber 1 is provided, and the gas-air mixture chamber 1 is connected to a gas-air mixture inlet 3 . In order to achieve the purpose of safe and reliable combustion system, adjustable temperature and uniform temperature field, a premixed combustion method is adopted, and the nozzle is designed as a ring structure nozzle with three rows of holes arranged alternately, in order to eliminate the unsafety of premixed combustion .

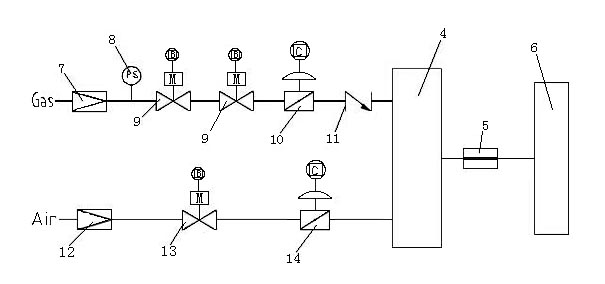

[0015] Such as image 3 As shown, the present invention also includes a set of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com