Electrohydraulic energy regenerative vibration absorber

A technology of shock absorber and accumulator, applied in the direction of liquid shock absorber, etc., can solve the problems of low efficiency of energy feed system, inferior to passive suspension, low overall system efficiency, etc., and achieve the effect of active control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

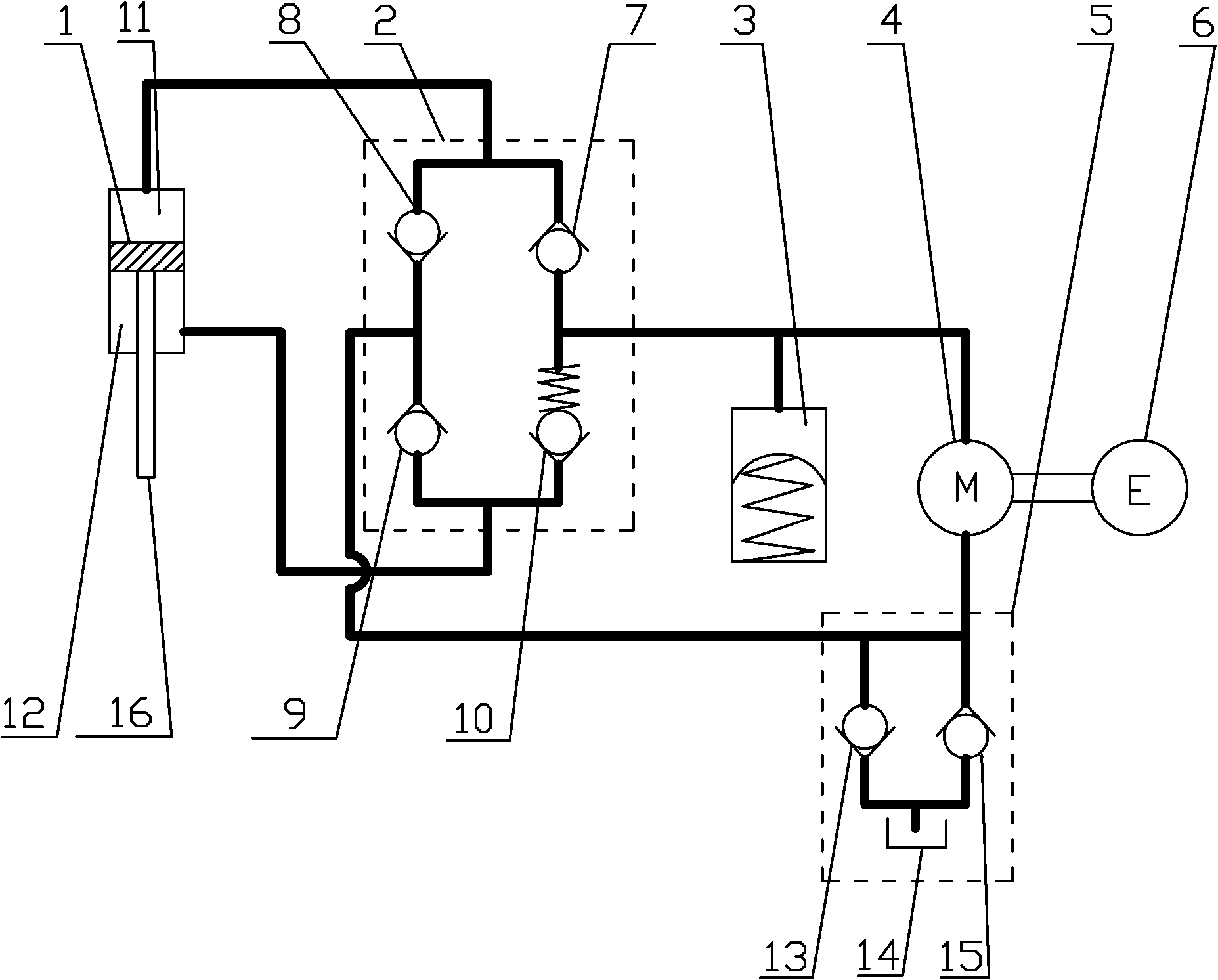

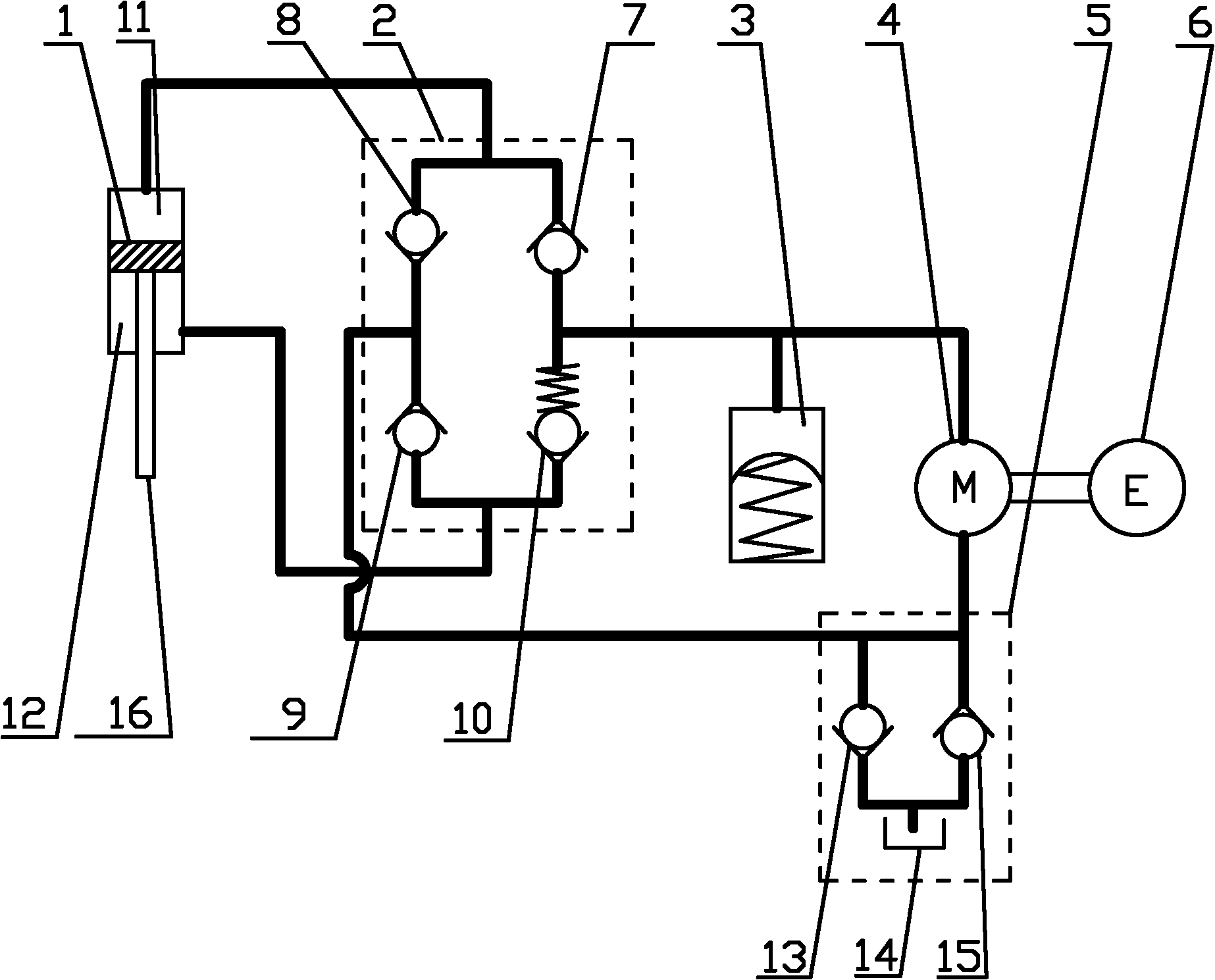

[0020] The liquid-electric energy-feeding shock absorber provided by the present invention has a structure such as figure 1 As shown, it includes piston 1, hydraulic check bridge 2, accumulator 3, hydraulic motor 4, volume conversion bridge 5 and rotary generator 6, wherein: the shock absorber cavity is divided into no The rod cavity 11 and the rod cavity 12, each of these two parts of the cavity has an oil outlet and an oil inlet, and each oil outlet and oil inlet is provided with a one-way valve, and the one-way valve is connected with it The connected pipeline constitutes the hydraulic check bridge 2; the accumulator 3 is connected in parallel on the connecting pipeline between the two oil outlets and the oil inlet of the hydraulic motor 4; between the oil outlet of the hydraulic motor 4 and the shock absorber cavity A volume conversion bridge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com