Undersize-hole oil pipe plugging device

A tubing plug, too small technology, applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problems of reliable clogging of tubing, high cost, not easy to clog, etc., to protect the environment And the effect of safe production, high safety in use, and high reliability of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

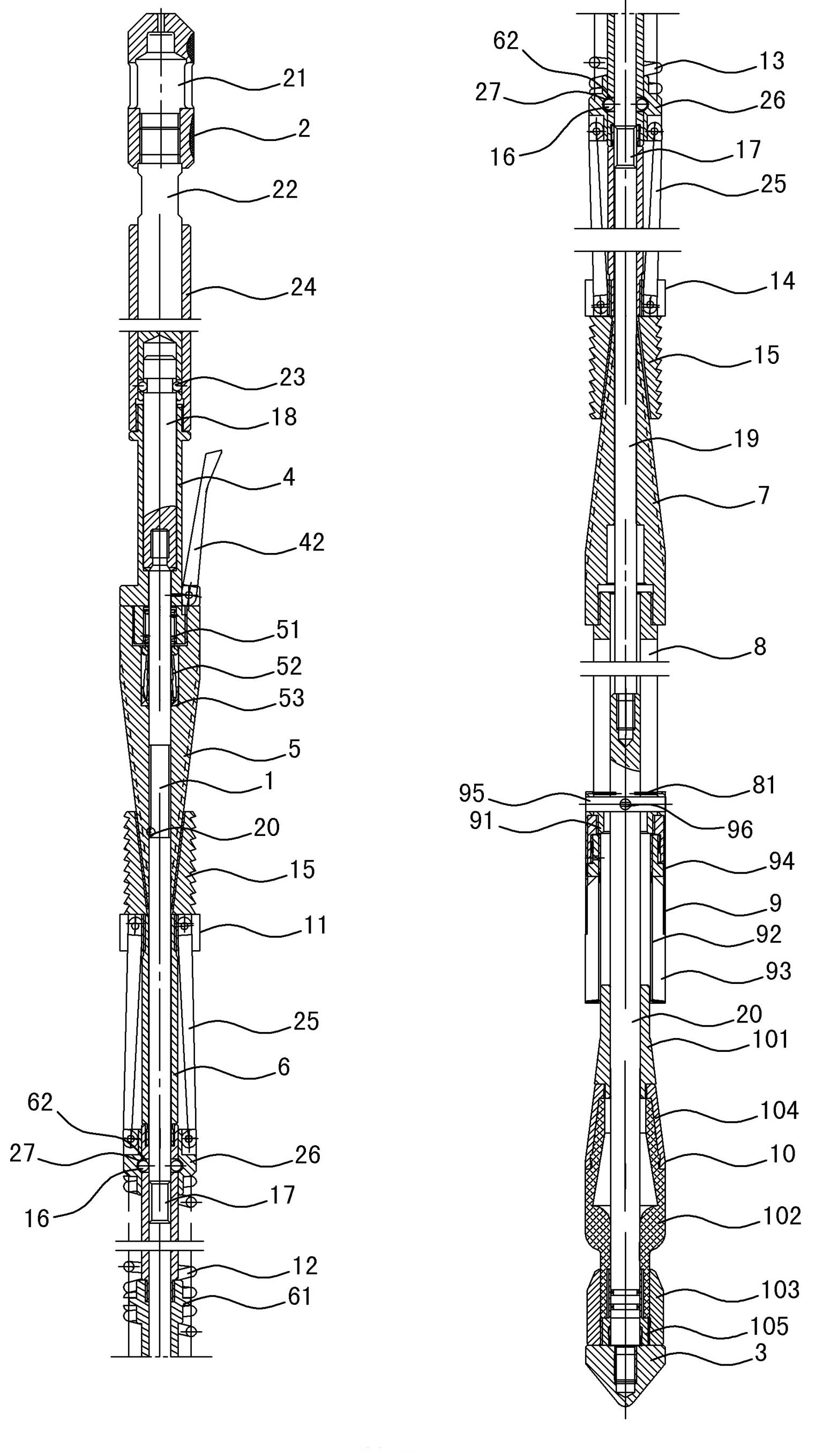

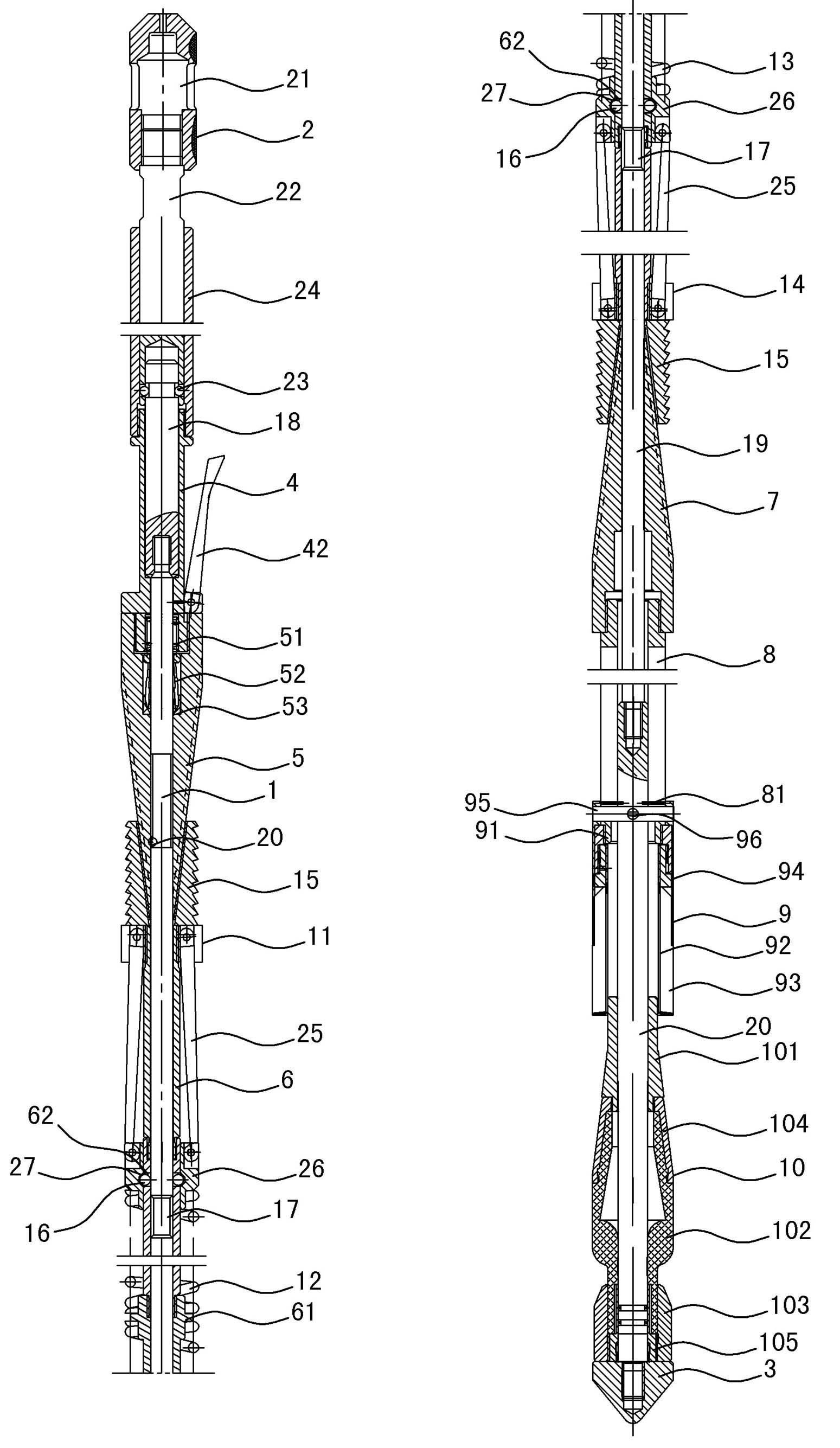

[0015] As shown in the figure, it includes a core rod 1. The upper end of the core rod 1 is connected with the feeder body 2, and the lower end is connected with the guide head 3. The upper end of the core rod 1 is connected with the head feeder body 2 and the guide head 3 from top to bottom. The set includes claw assembly 4, upper slip guide cone sleeve 5, middle connecting sleeve 6, lower slip guide cone sleeve 7, lower connecting sleeve 8, sheath assembly 9 and plugging assembly 10, upper slip guide cone Sleeve 5, middle connecting sleeve 6, lower slip guide tapered sleeve 7, lower connecting sleeve 8 and sheath assembly 9 are fixedly connected from top to bottom in sequence, middle connecting sleeve 6 and core rod 1 are guided by upper slips The upper slip assembly 11, the upper compression spring 12, the lower compression spring 13 and the lower slip assembly 14 are arranged sequentially from top to bottom between the taper sleeve 5 and the lower slip guide taper sleeve 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com