Coating film supporting mechanism of high temperature deposition hard mask of film coating workpiece

A technology of supporting mechanism and workpiece, applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problem of crushing infrared light window and other problems, achieve large supporting force, uniform contact force and low friction force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

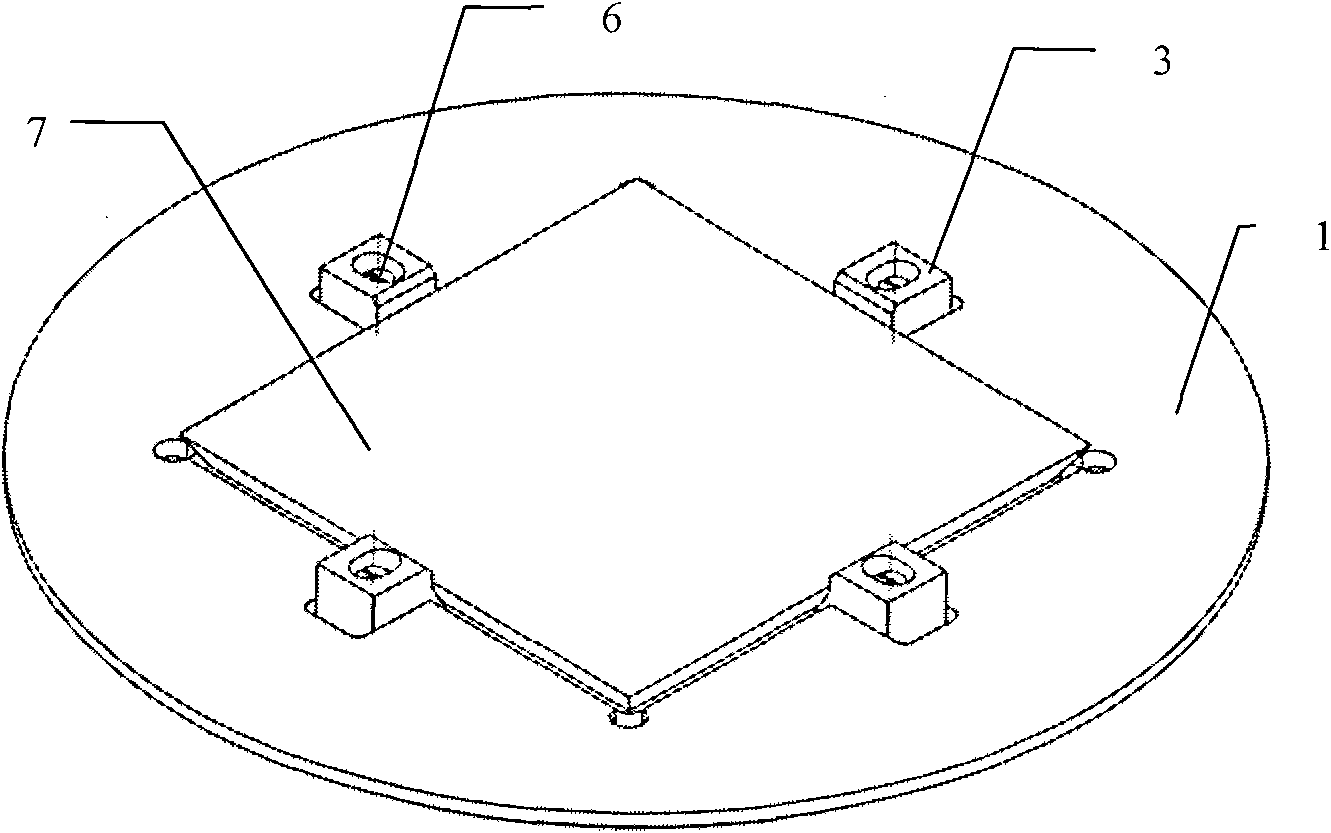

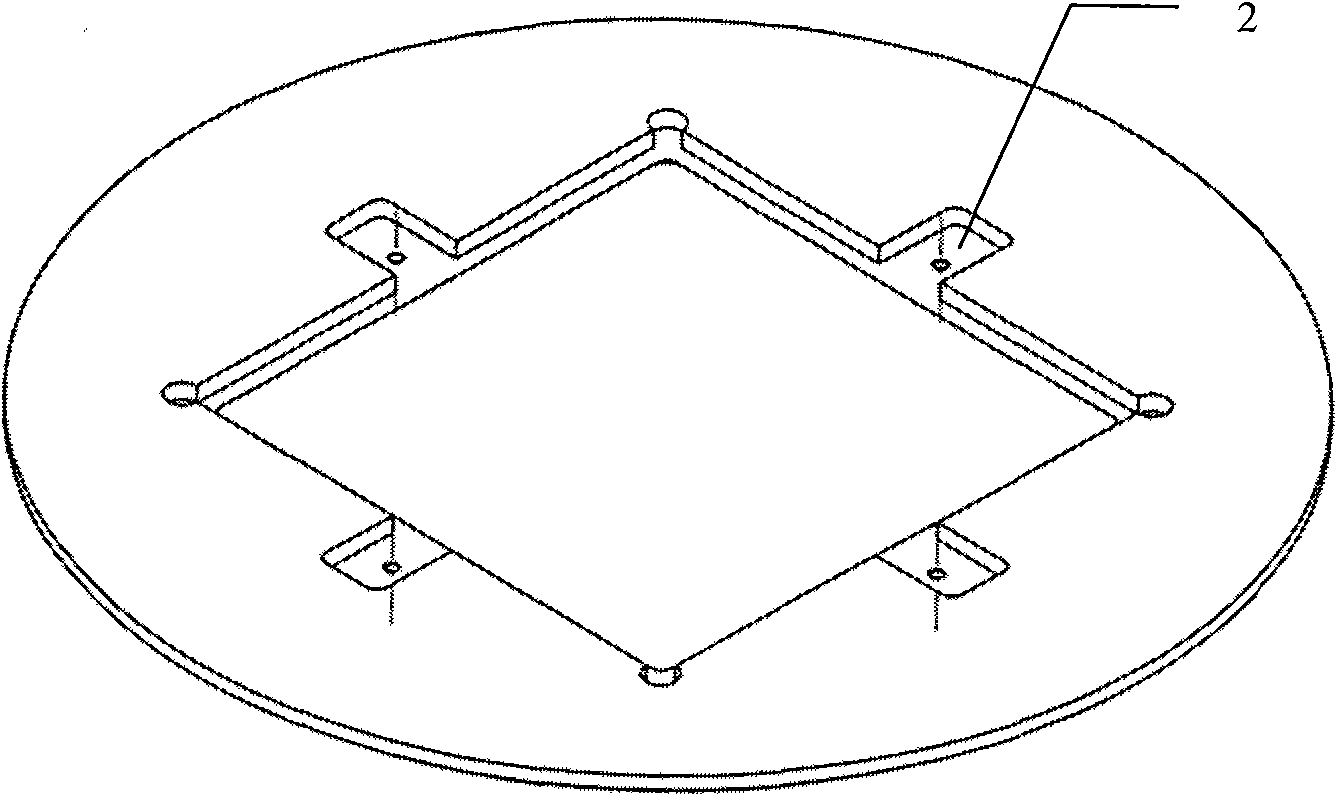

[0010] Taking the coated infrared light window as an example to illustrate the use process of the coating support mechanism:

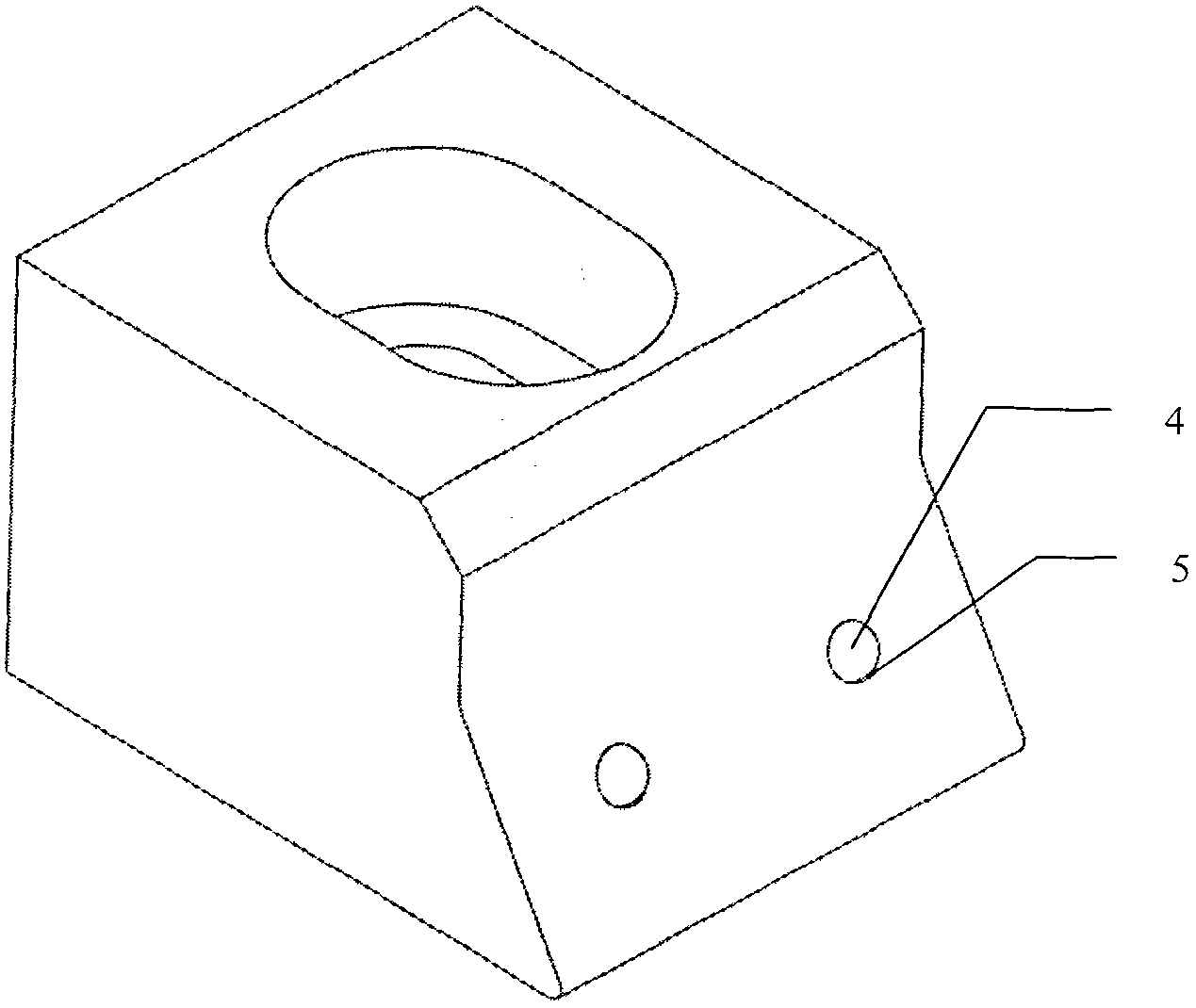

[0011] Clean the coating tray, workpiece stopper, and locking screws, and fix the workpiece stopper on the coating tray with locking screws according to the size of the workpiece. Place the coating workpiece on the coating support device, so that the steel ball is in uniform contact with the inclined surface of the workpiece. Then, put the workpiece and the whole device into the ring tray of the coating machine, heat up, coat and cool down. After the coating machine is completely cooled, remove the workpiece and the coating support device together, unload the coating workpiece, and complete the coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com