Method for recovering gold and silver from waste circuit boards

A technology for recycling gold from waste circuit boards, applied in the field of recycling gold and silver, can solve the problems of unstable gold leaching agent, serious pollution, high cost, etc., and achieve the effects of easy industrialization, efficient recycling, and high leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

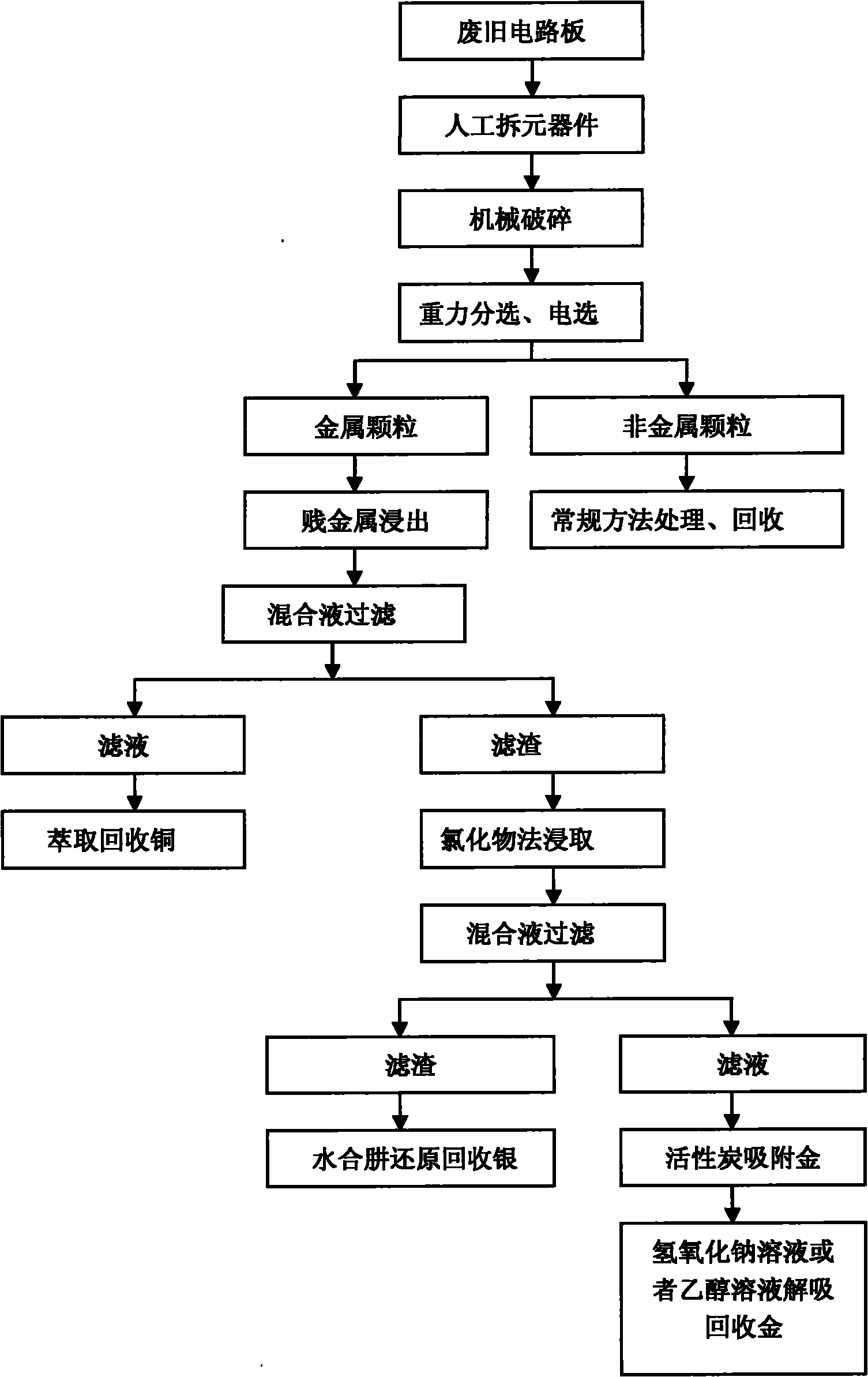

Image

Examples

Embodiment 1

[0026] Using waste circuit boards as raw materials, after pretreatment such as crushing and sorting, the complete separation of metals and non-metals is realized, and non-metals are subjected to conventional recycling treatment, and metal particles and sulfuric acid solution (concentration: 6m / L) are poured into the In the reactor, the solid-to-liquid ratio of the two is 1:8, heated to 75°C, and the oxidant sodium chlorate is added under stirring, the mass ratio of the metal to the oxidant sodium chlorate is 1:0.1, and the reaction continues after the addition of the oxidant After 3 hours, the reacted mixture is filtered, and the filtrate is used to recover copper and other metals by solvent extraction of copper. The solid after solid-liquid separation is the gold and silver leaching raw material. Use hydrochloric acid to adjust the pH of the solution to 1.5, then add chloride, which is sodium chloride, so that the concentration of chloride in the solution is 5M / L, and then add...

Embodiment 2

[0031] Using waste circuit boards as raw materials, after pretreatment such as crushing and sorting, the complete separation of metals and non-metals is realized, and non-metals are subjected to conventional recycling treatment, and metal particles and sulfuric acid solution (concentration: 6m / L) are poured into the In the reactor, the solid-to-liquid ratio of the two is 1:10, heated to 75°C, and the oxidant sodium chlorate is added under stirring, the mass ratio of the metal to the oxidant sodium chlorate is 1:0.15, and the reaction continues after the addition of the oxidant After 2 hours, the reacted mixture is filtered, and the filtrate is used to recover copper and other metals by solvent extraction of copper. The solid after solid-liquid separation is the raw material for leaching gold and silver. Use hydrochloric acid to adjust the pH of the solution to 2, then add chloride, which is sodium chloride, so that the concentration of chloride in the solution is 7M / L, and then...

Embodiment 3

[0036] Using waste circuit boards as raw materials, after pretreatment such as crushing and sorting, the complete separation of metals and non-metals is realized, and non-metals are subjected to conventional recycling treatment, and metal particles and sulfuric acid solution (concentration: 1m / L) are poured into the In the reactor, the solid-to-liquid ratio of the two is 1:3, heated to 70°C, and the oxidant sodium chlorate is added under stirring, the mass ratio of the metal to the oxidant sodium chlorate is 1:0.08, and the reaction continues after the oxidant is added. After 1h, the reacted mixture is filtered, and the filtrate is used to recover copper and other metals by solvent extraction of copper. The solid after solid-liquid separation is the gold and silver immersion raw material. Use hydrochloric acid to adjust the pH of the solution to 1, then add chloride, which is sodium chloride, so that the concentration of chloride in the solution is 4M / L, and then add gold leach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com