Low-smoke, zero-halogen and flame-retardant multi-core controlled cable sheath rubber for railway vehicles

A technology for rail vehicles and control cables, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of easy expansion of wire core insulating rubber, easy thinning of wire cores, affecting production quality, etc. Excellent performance, anti-aging ability and anti-fatigue ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

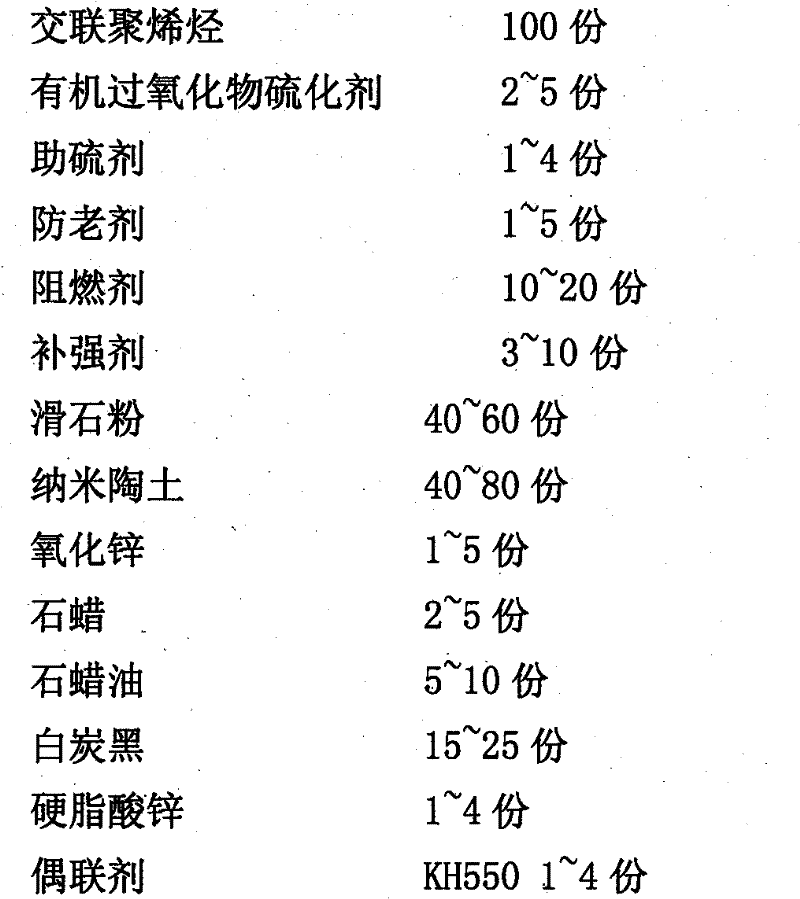

[0034] A multi-core control cable sheath rubber for low-smoke, halogen-free, flame-retardant rail vehicles according to the present invention, the sheath rubber mainly includes the following components by weight:

[0035] Cross-linked polyolefin 100 parts

[0036] 3 parts of organic peroxide vulcanizing agent

[0037] 2 parts of auxiliary sulfur agent

[0038] Anti-aging agent 3 parts

[0039] Flame retardant 15 parts

[0040] Reinforcing agent 8 parts

[0041] Talcum powder 50 parts

[0042] Nano clay 60 parts

[0043] 3 parts zinc oxide

[0044] 3 parts paraffin

[0045] 8 parts paraffin oil

[0046] White carbon black 20 parts

[0047] 3 parts zinc stearate

[0048] 3 parts of coupling agent KH550.

[0049] Among them, the cross-linked polyolefin is preferably ethylene ethyl acetate EVM700 produced by DuPont Company, the organic peroxide curing agent is preferably dicumyl peroxide DCP, the sulfur assistant is triallyl isocyanuric acid ester TAIC, and the anti-agi...

Embodiment 2

[0056] Yet another low-smoke, halogen-free, flame-retardant rail vehicle sheath rubber for multi-core control cables according to the present invention, the sheath rubber mainly includes the following components by weight:

[0057] Cross-linked polyolefin 100 parts

[0058] Organic peroxide vulcanizing agent 5 parts

[0059] 4 parts of auxiliary sulfur agent

[0060] Anti-aging agent 5 parts

[0061] Flame retardant 20 parts

[0062] Strengthening agent 10 parts

[0063] Among them, the cross-linked polyolefin is preferably ethylene ethyl acetate EVM700 produced by DuPont Company, the organic peroxide curing agent is preferably dicumyl peroxide DCP, the sulfur assistant is triallyl isocyanuric acid ester TAIC, and the anti-aging agent is preferably anti-aging Agent XH-3, the flame retardant is preferably zinc borate, and the reinforcing agent is preferably N550 carbon black.

Embodiment 3

[0065] Yet another low-smoke, halogen-free, flame-retardant rail vehicle sheath rubber for multi-core control cables according to the present invention, the sheath rubber mainly includes the following components by weight:

[0066] Cross-linked polyolefin 100 parts

[0067] Organic peroxide vulcanizing agent 2 parts

[0068] 1 part of auxiliary sulfur agent

[0069] Anti-aging agent 1 part

[0070] Flame retardant 10 parts

[0071] Reinforcing agent 3 parts

[0072] Talcum powder 60 parts

[0073] Nano clay 40 parts

[0074] Zinc oxide 5 parts

[0075] 2 parts paraffin

[0076] 10 parts paraffin oil

[0077] White carbon black 15 parts

[0078] Zinc stearate 4 parts

[0079] 4 parts of coupling agent KH550.

[0080] Among them, the cross-linked polyolefin is preferably ethylene ethyl acetate EVM700 produced by DuPont Company, the organic peroxide curing agent is preferably dicumyl peroxide DCP, the sulfur assistant is triallyl isocyanuric acid ester TAIC, and the an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com