Enhanced fiber unit and manufacturing method thereof

An optical fiber unit and enhanced technology, which is applied in the field of enhanced optical fiber unit and its production, can solve the problems of not having mechanical protection functions such as tensile and compressive resistance, etc., so as to improve tensile performance, ensure integrity and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

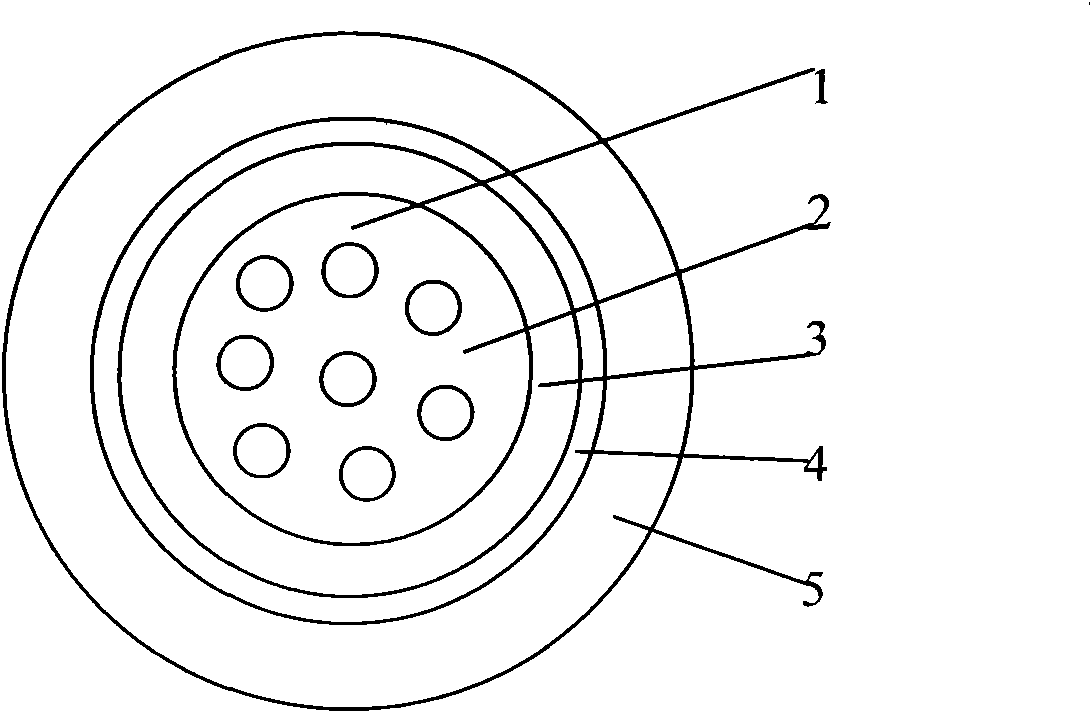

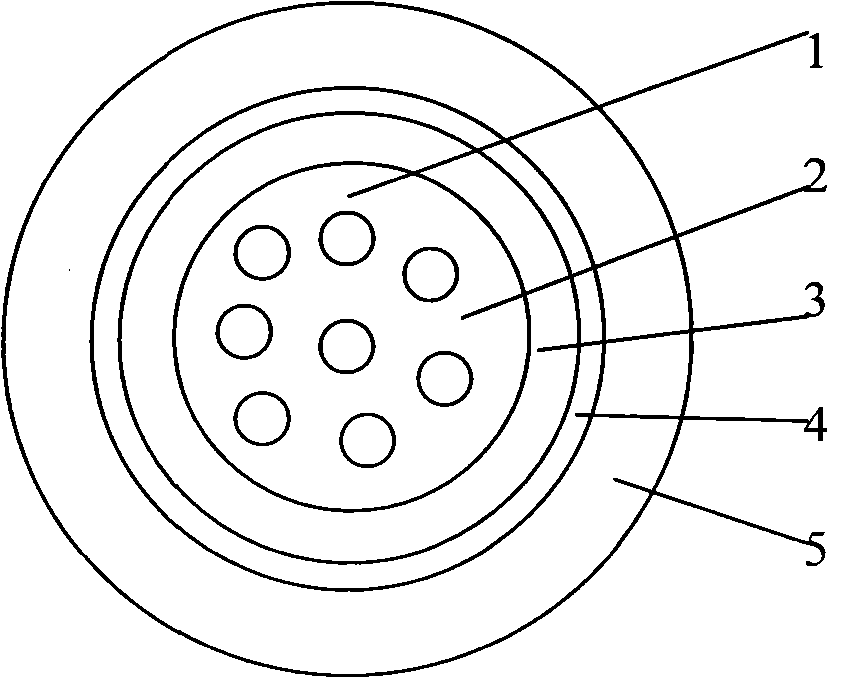

[0017] Refer to attached figure 1 The enhanced optical fiber unit includes several optical fibers 1 , optical fiber filling grease 2 , optical fiber protection layer 3 , fiber reinforcement layer (reinforcement element) 4 , and reinforcement outer sheath layer 5 . A fiber protection layer 3 is wrapped outside several optical fibers 1, and there is an optical fiber filling ointment 2 between several fibers in the fiber protection layer 3, and a fiber reinforcement layer (reinforcement element) 4 is arranged outside the fiber protection layer, and the fiber reinforcement layer (Strengthening element) 4 has a reinforced outer sheath 5 on the outside.

[0018] Optical fiber 1 is mainly made of high-purity quartz through coarse and fine processing. The optical fiber protective layer 3 is a plastic protective layer (PBT loose tube) that is tightly wrapped or loosely wrapped around the optical fiber. The fiber-reinforced layer (reinforcing element) adopts non-metallic high-strength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com