Intelligent three-phase equipment safety detector

A detector and intelligent technology, which is applied in the field of intelligent three-phase equipment safety detectors, can solve the problems of low intelligence, low work efficiency, and poor measurement accuracy, and achieve the goal of improving the technical level, convenient operation, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

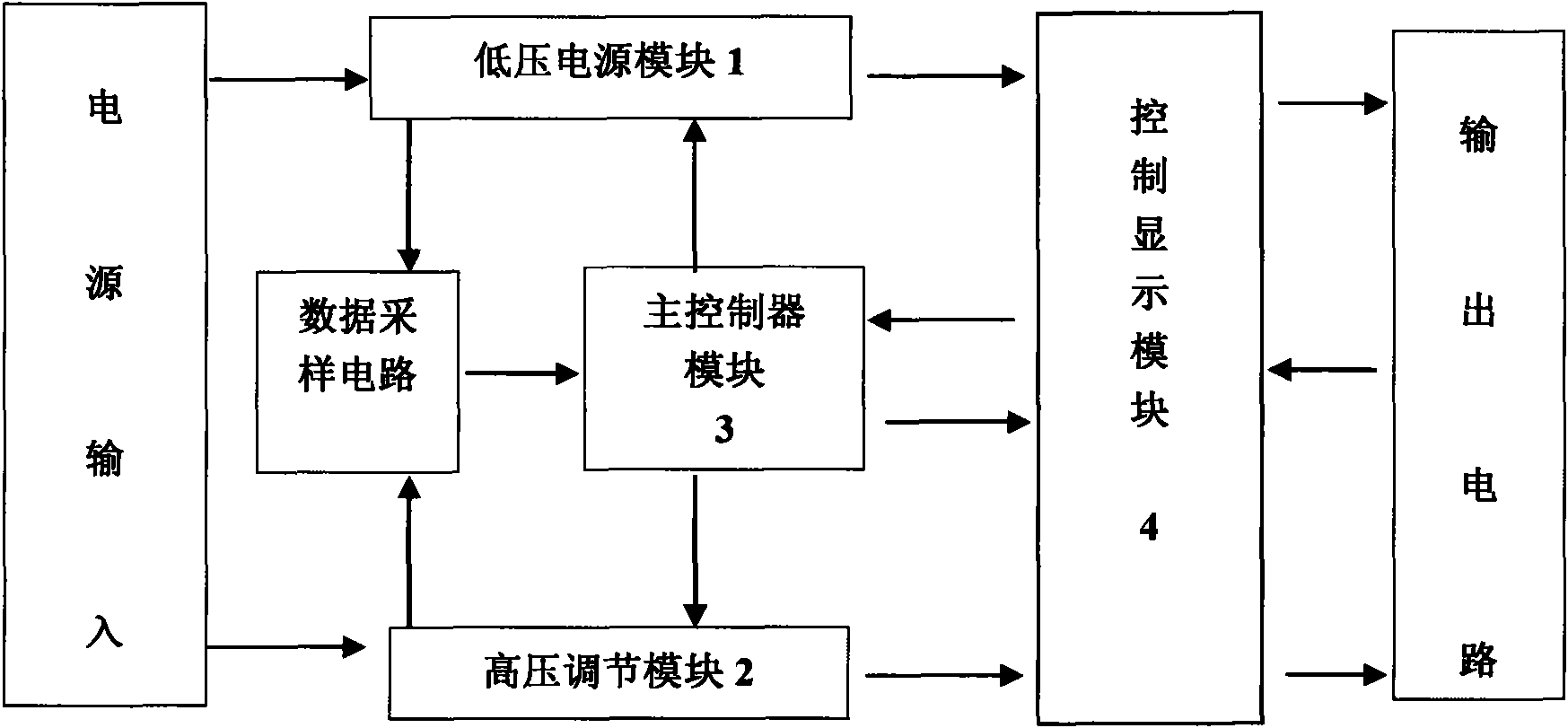

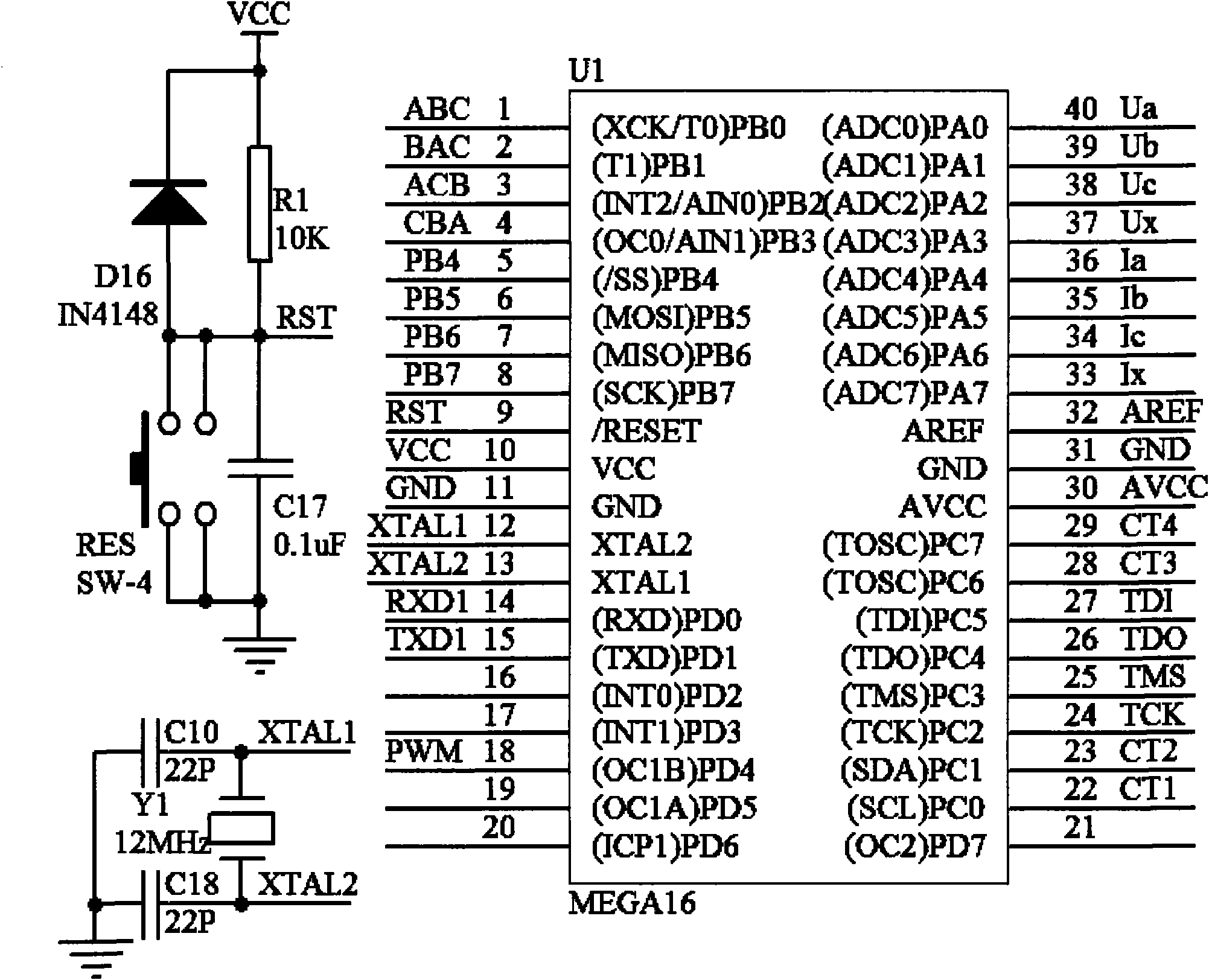

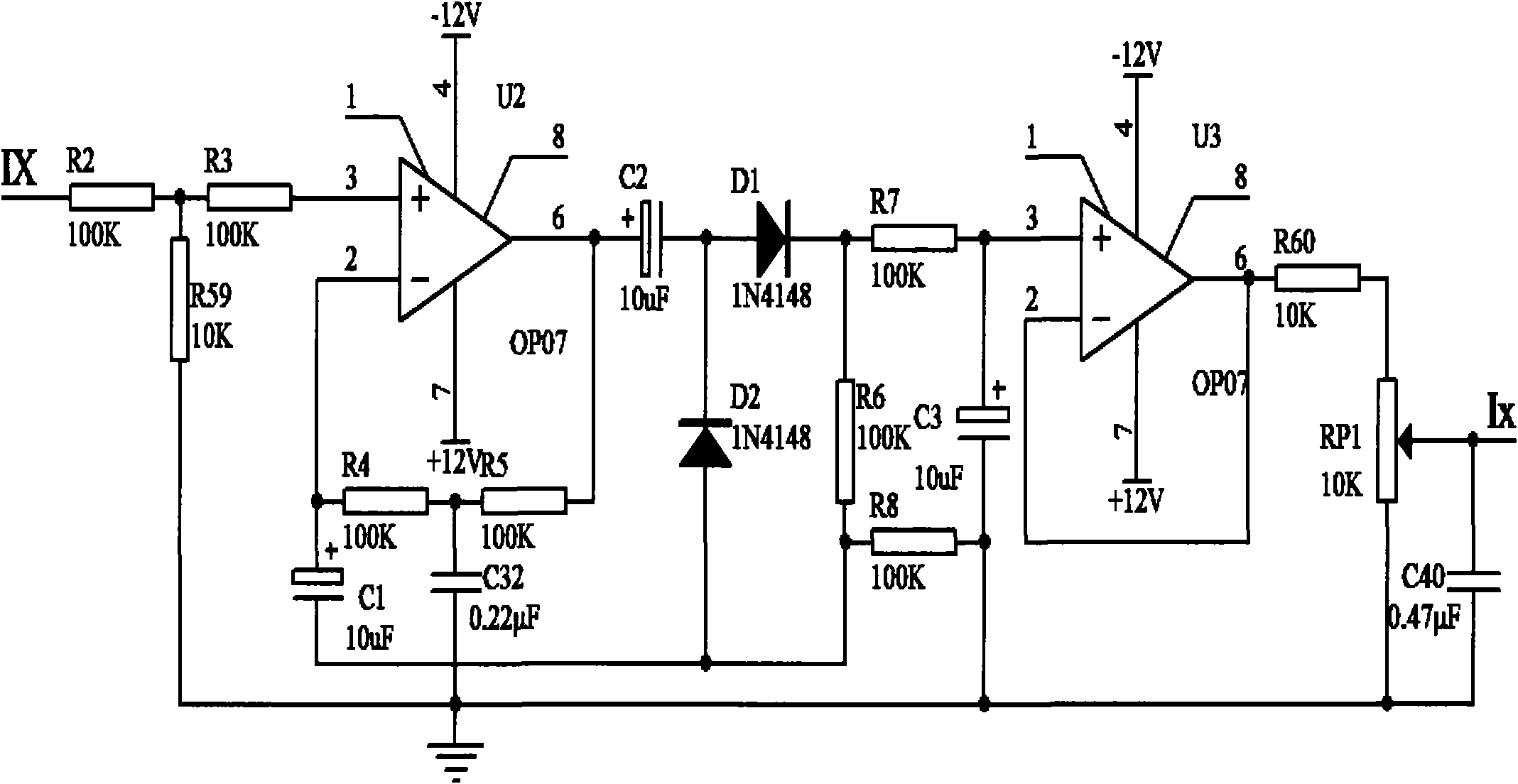

[0016] An intelligent three-phase equipment safety detector according to the present invention, figure 1 It is a structural block diagram of the present invention. The safety detector includes a low-voltage power supply module 1, a high-voltage power supply module 2, a main controller module 3 and a control display module 4, wherein the main controller module 3 controls the circuits of the other three modules. The low-voltage power supply module 1, the high-voltage power supply module 2 and the control display module 4 are all connected to the main controller module 3; the main controller module 3 collects and calculates the data sampling circuit 5, and displays the measurement results through the control display module 4; The low-voltage power supply module 1 provides a stable power supply to the external device under test; the high-voltage power supply module 2 provides high voltage for measuring the insulation performance and high-voltage resistance performance of the equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com