Device and method for rapidly measuring viscosity of high-temperature melt by using free vibration method of spring oscillator

A rapid measurement, spring oscillator technology, applied in the field of metallurgy and casting, can solve the problem of real-time detection limitation of test methods, and achieve the effect of sufficient and reliable mathematical basis, easy acquisition and processing, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The device for quickly measuring the viscosity of high-temperature melts by the free vibration method of a spring vibrator consists of: a vane vibrator 1, the vane vibrator 1 is connected to one end of the connecting rod 2, and the spring 3 is inserted into the connecting rod 2 to connect as a whole. The other end of the connecting rod 2 is connected to the permanent magnet 4, the outer ring of the permanent magnet is covered with a coil 5, the size of the coil is greater than the outer ring size of the permanent magnet, and the coil 5 is connected to the signal amplification processor 6. The signal amplifying processor 6 is connected to a computer 7, and the vane vibrator 1 extends into the crucible 8.

[0019] The device for rapidly measuring the viscosity of high-temperature melts by the spring oscillator free vibration method, the measured melt 9 is installed in the crucible 8, and the crucible 8 is placed on the platform 10 directly below the blade oscillator 1, and...

Embodiment 2

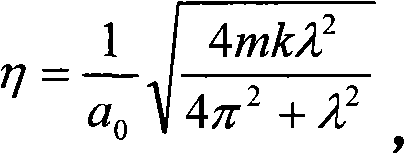

[0021] The device and method for quickly measuring the viscosity of a high-temperature melt by the spring vibrator free vibration method described in Example 1, hangs a blade vibrator with a mass m on a vertically suspended spring to form a spring vibrator, and the vibrator vibrates vertically in the liquid When , due to the velocity gradient between different liquid layers, when one liquid layer moves relative to another liquid layer, there will be internal friction force tangential to the surface of the liquid layer. When the shape of the vibrator is fixed and the vibration does not cause turbulence or the turbulence is very small, the internal friction force on the vibrator is proportional to the velocity gradient.

[0022] Let f be the internal friction force on the vibrator, s be the total area of friction between the vibrator and the liquid layer, is the velocity gradient between liquid layers, and η is the dynamic viscosity value of the liquid. According to the relev...

Embodiment 3

[0068] The method for quickly measuring the viscosity of high-temperature melts by the free vibration method of the spring vibrator,

[0069] The calibration of the system constants:

[0070] The parameters of the system should be calibrated before each use; a standard liquid produced by the National Metrology Institute is used as the standard liquid to calibrate the parameters of the system; the software program of the system is set to the parameter calibration state, and the program requires the input of the m value k value of the system and the viscosity parameters of the standard liquid, follow the program prompts,

[0071] (1) Place the crucible containing the liquid to be tested directly below the weak spring vibrator;

[0072] (2) Rotate the compass of the lifting mechanism so that the spring vibrator slowly descends and immerses into the center of the liquid to be tested;

[0073] (3) Start the computer signal acquisition system to make it in the signal acquisition s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com