Extraction technology of gambogic acid

An extraction process, the technology of gambogic acid, which is applied in the field of medicine, can solve the problems of unfavorable industrial scale-up production, cumbersome operation steps, and low extraction yield, and achieve the effects of recyclable solvent, high purity, and fast extraction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

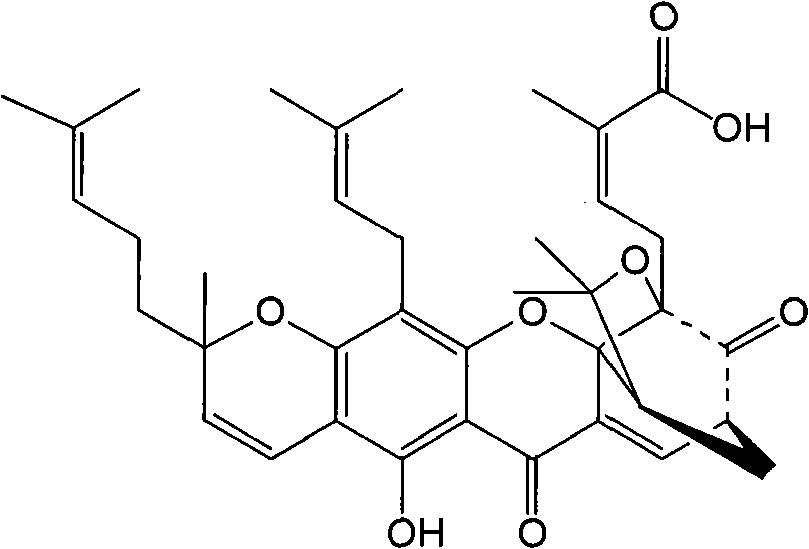

Image

Examples

Embodiment 1

[0017] Embodiment 1 A kind of extraction process of gambogic acid

[0018] Proceed as follows:

[0019] (1) Weigh Garcinia cambogia 6kg, pulverize into 50 mesh powder, add 12kg of silica gel (silica gel is pretreated in advance: add 8000mL methanol to silica gel to wash silica gel, to dryness. Wash silica gel with 8000mL of ethyl acetate again, to dryness ) uniformly mixed, filled into a chromatographic column with a diameter of 50 cm, and eluted with ethyl acetate. The eluent was initially dark brown, and the elution was stopped when the eluent turned pale yellow. Concentrate under reduced pressure at 40°C and recover the solvent to obtain a yellow primary extract of gambogic acid.

[0020] (2) Dissolve the primary extract of gambogic acid in pyridine (mass volume (g:ml) ratio 1:2), fully shake for 1 hour, add 1 volume of 50°C distilled water of the mixture, stir well, let stand, after cooling There was solid precipitation, suction filtration, and drying to obtain 1.89Kg of...

Embodiment 2

[0024] Embodiment 2 A kind of extraction process of gambogic acid

[0025] Proceed as follows:

[0026] (1) Weigh 6kg of Garcinia cambogia, pulverize it into 30 mesh powder, add 24kg of diatomaceous earth and mix evenly, fill it into a chromatographic column with a diameter of 80cm, elute with methanol, the eluent is initially dark brown, and the eluent is The elution was stopped when light yellow, the eluate was collected, the eluate was concentrated under reduced pressure at 40° C. and the solvent was recovered to obtain a yellow paste-like primary extract of gambogic acid.

[0027] (2) dissolving the first extract of gambogic acid in triethylamine (mass volume (g: ml) ratio 2: 1), fully shaken for 1 hour, add 4 times the volume of distilled water of the mixture and fully stir for 2 hours, after standing A solid was precipitated, which was filtered off with suction and dried to obtain 1.98Kg of crude gambogic acid triethylamine salt.

[0028] (3) the obtained gambogic acid...

Embodiment 3

[0031] Embodiment 3 A kind of extraction process of gambogic acid

[0032] Proceed as follows:

[0033] (1) take by weighing garcinia resin 6kg, pulverize into 60 mesh powder; Add 6kg quartz powder (quartz powder is pretreated in advance: add 8000mL methanol washing quartz powder in quartz powder, to dry. Wash with 8000mL ethyl acetate again Quartz powder, to dryness), evenly mixed, filled into a chromatographic column with a diameter of 50 cm, and eluted with an organic solvent (volume ratio of methanol and dichloromethane is 1:1), the eluent was initially dark brown, and the eluent was When light yellow, the elution was stopped, the eluate was collected, the eluate was concentrated under reduced pressure at 40° C. and the solvent was recovered to obtain a yellow primary extract of gambogic acid.

[0034] (2) dissolving the gambogic acid initial extract in pyridine (mass volume (g: ml) ratio 1: 3), fully shaken for 1 hour, add 2 times the volume of distilled water of the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com