Preparation method of Mildronate intermediate

The technology of an intermediate, Meldonium, is applied in the field of preparation of Meldonium intermediate, that is, 3-methyl propionate salt, which can solve the problems of flammability, high volatility, and potential safety hazards, and reduce energy consumption and reduce Effects of investment in equipment and improvement in safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

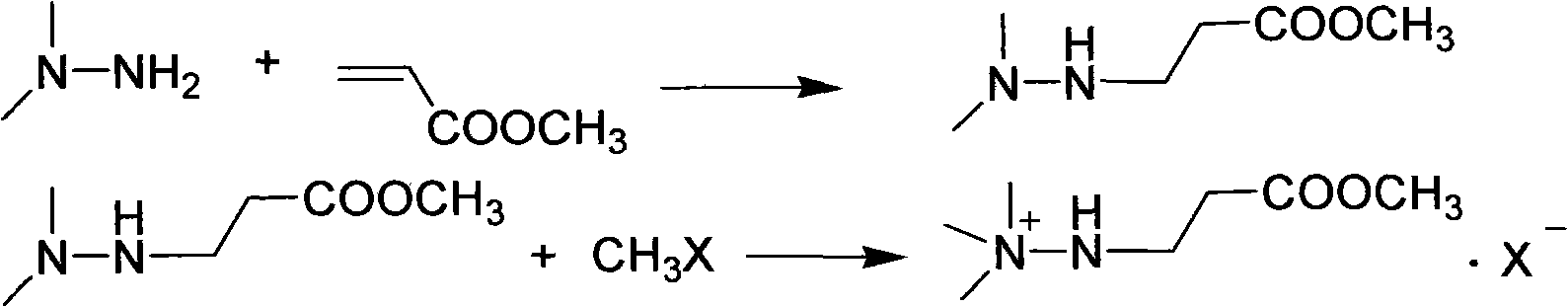

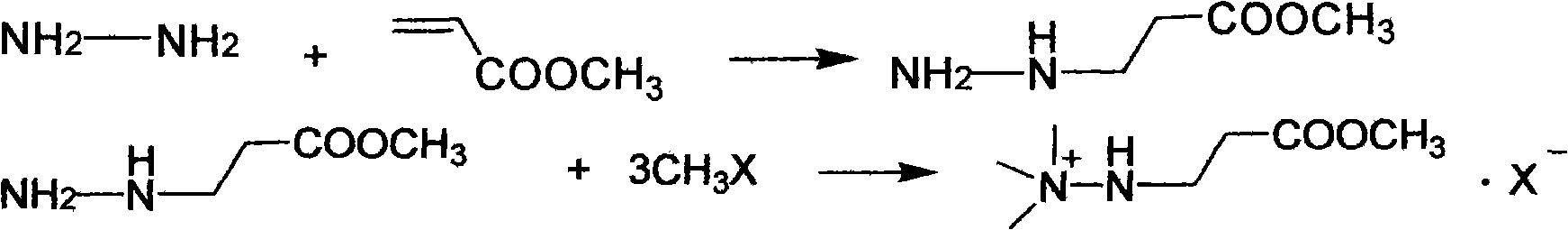

Method used

Image

Examples

Embodiment 1

[0032] In the there-necked flask with mechanical stirring and dropping funnel, add methyl acrylate 86g (1mol), 95% ethanol 60ml, control temperature at 20-30 ℃, add dropwise the hydrazine hydrate of 80% 68.8g (1.1mol), After 1.5 hours of dripping, continue to stir at the same temperature for 1 hour, first distill ethanol under normal pressure, and then distill 93.8 g of methyl 3-hydrazinopropionate under reduced pressure, with a yield of 79.5% and a content of 98.8% (GC);

[0033] Dissolve the above distillation product in 150ml of ethanol, control the temperature at 20-30°C, pass in 237.9g of methyl bromide, and at the same time pass in ammonia gas as an acid-binding agent for 1 hour, continue stirring at the same temperature for 1 hour, filter, and wash with cold ethanol , and dried to obtain 174.3 g of methyl 3-(2,2,2-trimethylhydrazine)propionate bromide, with a yield of 91.0% and a content of 99.1% (HPLC).

Embodiment 2

[0035] Add 86g (1mol) of methyl acrylate and 60ml of methanol in a three-necked flask with mechanical stirring and dropping funnel, control the temperature at 30-40°C, add 80% of 65.6g (1.05mol) of hydrazine hydrate dropwise, time 1 After hours of dripping, continue to stir at the same temperature for 1 hour, first distill methanol at normal pressure, and then distill 92.5 g of methyl 3-hydrazinopropionate under reduced pressure, with a yield of 78.4% and a content of 99.0% (GC);

[0036] Dissolve the above-mentioned distillation product in 150ml of ethanol, control the temperature at 30-40°C, pass in 245.8g of methyl bromide, and at the same time pass in ammonia gas as an acid-binding agent for 1.5 hours, continue to stir at the same temperature for 1.5 hours, filter, and wash with cold ethanol , and dried to obtain 172.5 g of methyl 3-(2,2,2-trimethylhydrazine) propionate bromide, with a yield of 91.3% and a content of 99.1% (HPLC).

Embodiment 3

[0038] In the there-necked flask with mechanical stirring and dropping funnel, add methyl acrylate 86g (1mol), isopropanol 60ml, control the temperature at 40-50°C, add dropwise 80% of 68.8g (1.1mol) of hydrazine hydrate, After 2 hours of dripping, continue to stir at the same temperature for 2 hours, first distill isopropanol under normal pressure, and then distill 93.2g of methyl 3-hydrazinopropionate under reduced pressure, with a yield of 79.0% and a content of 98.7% (GC) ;

[0039] Dissolve the above-mentioned distillation product in 150ml of ethanol, control the temperature at 40-50°C, add 313.6g of dimethyl sulfate dropwise, and at the same time pass through ammonia gas as an acid-binding agent for 3 hours, continue to stir at the same temperature for 1 hour, filter, and use Wash with cold 50% ethanol and dry to obtain 181.8 g of methyl sulfate of methyl 3-(2,2,2-trimethylhydrazine)propionate, with a yield of 84.6% and a content of 98.5% (HPLC).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com