Ceramic filtering machine dehydrating system and dehydration technique thereof

A technology of ceramic filter and concentration tank, applied in the field of ceramic filter dehydration process and ceramic filter dehydration system, can solve the problems of clogging of micropores of ceramic filter plate, decreased cleaning effect, small output, etc., to improve production capacity and avoid a large number of blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

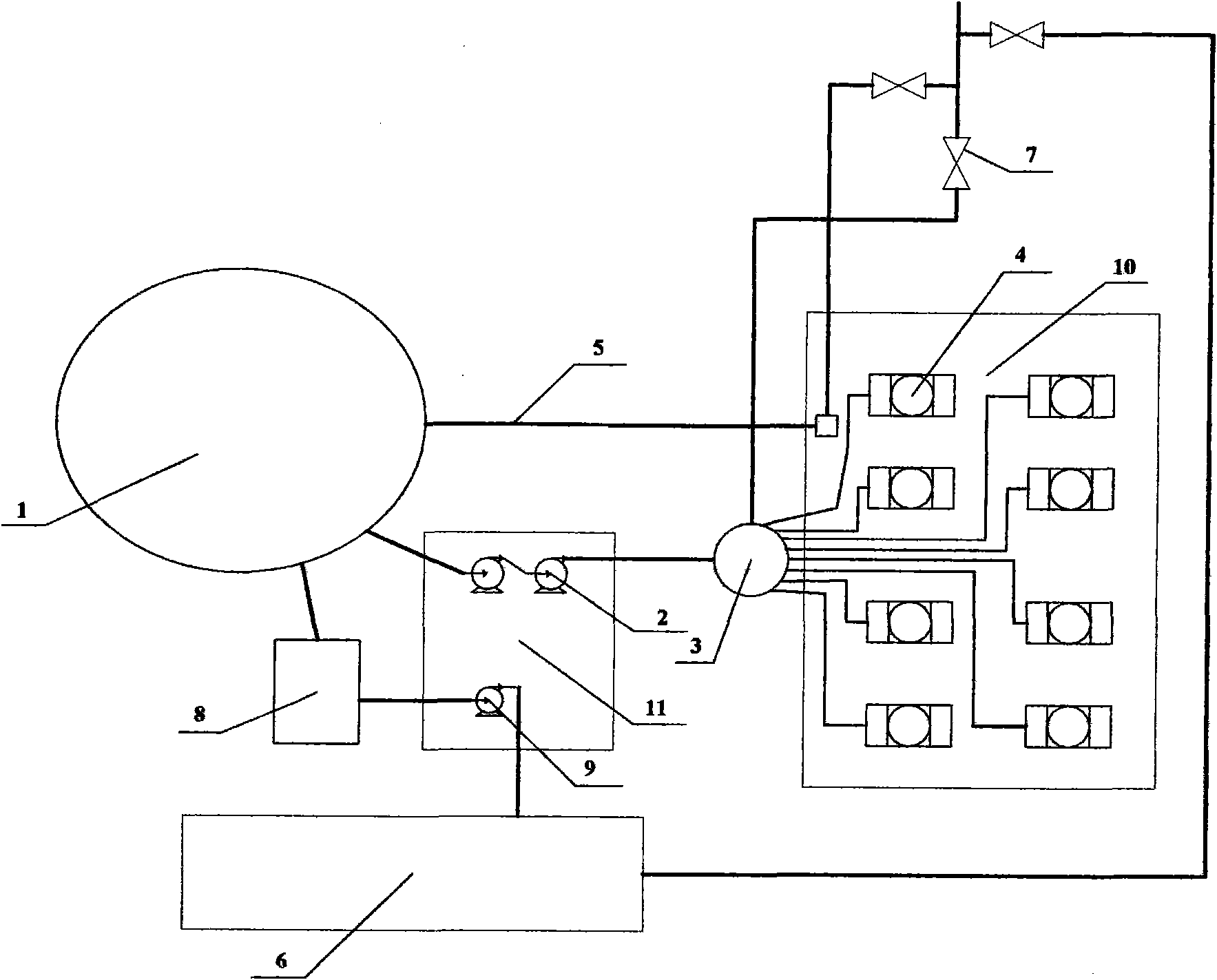

[0030] Combine below Figure 1-4 , the present invention will be further described.

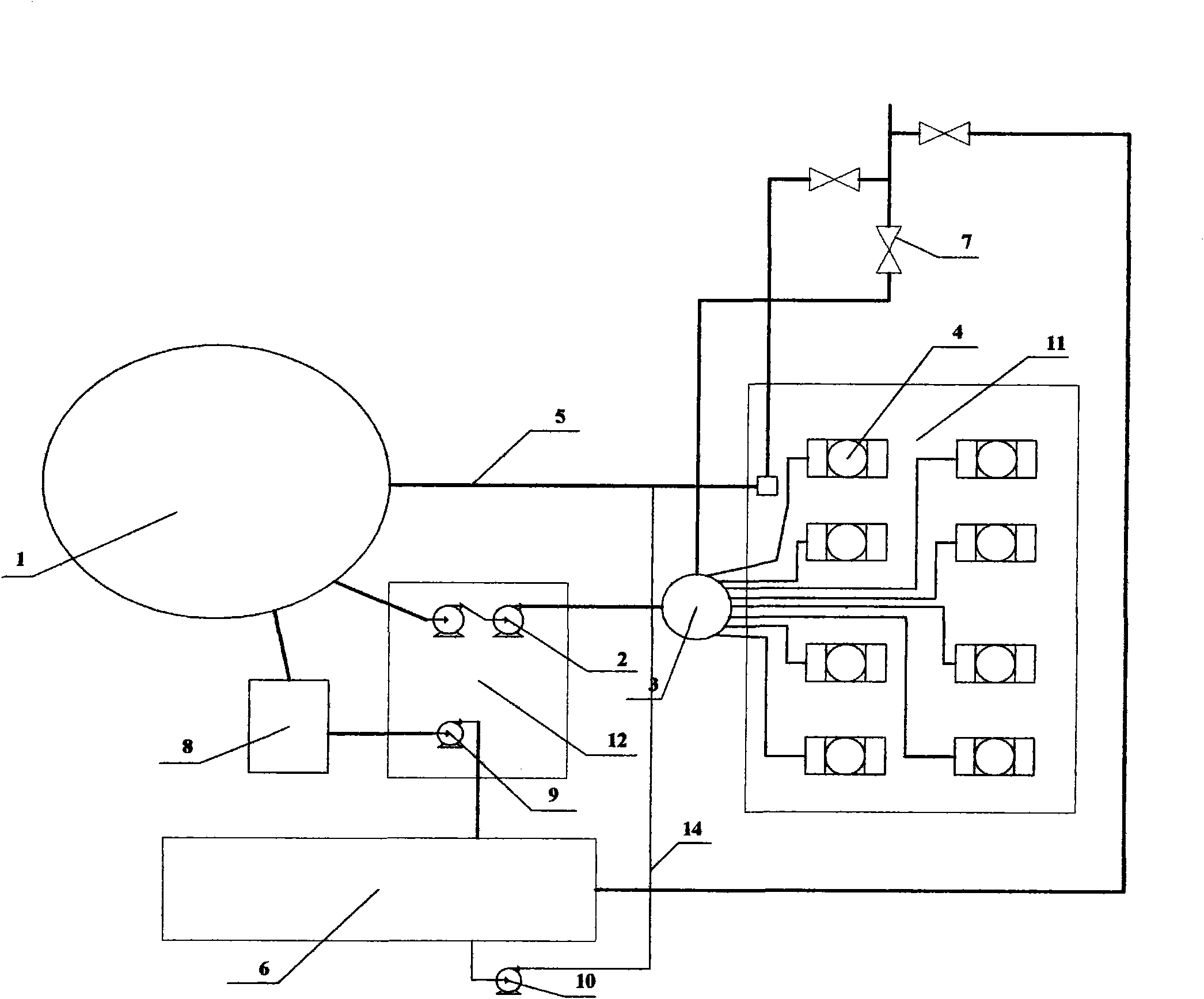

[0031] figure 2 Show the ceramic filter dehydration system provided by the present invention, in figure 1 Based on the prior art shown, the figure 2 In addition, a sewage pipeline connected to the accident pool 6 from the sewage pump 9 in the bottom flow pump room 12 is used for the overflow water of the concentration pool 1 to enter the accident pool 6 for precipitation. A new slurry pump 10 and an accident pool slurry pipe 14 are added after the accident pool 6 to connect the accident pool to the overflow pipe 5, which is used to stir the fine-grained ore deposited in the accident pool with water to the concentration pool 1 during the maintenance period, and then re-enter Dehydration workshop 11 is dehydrated.

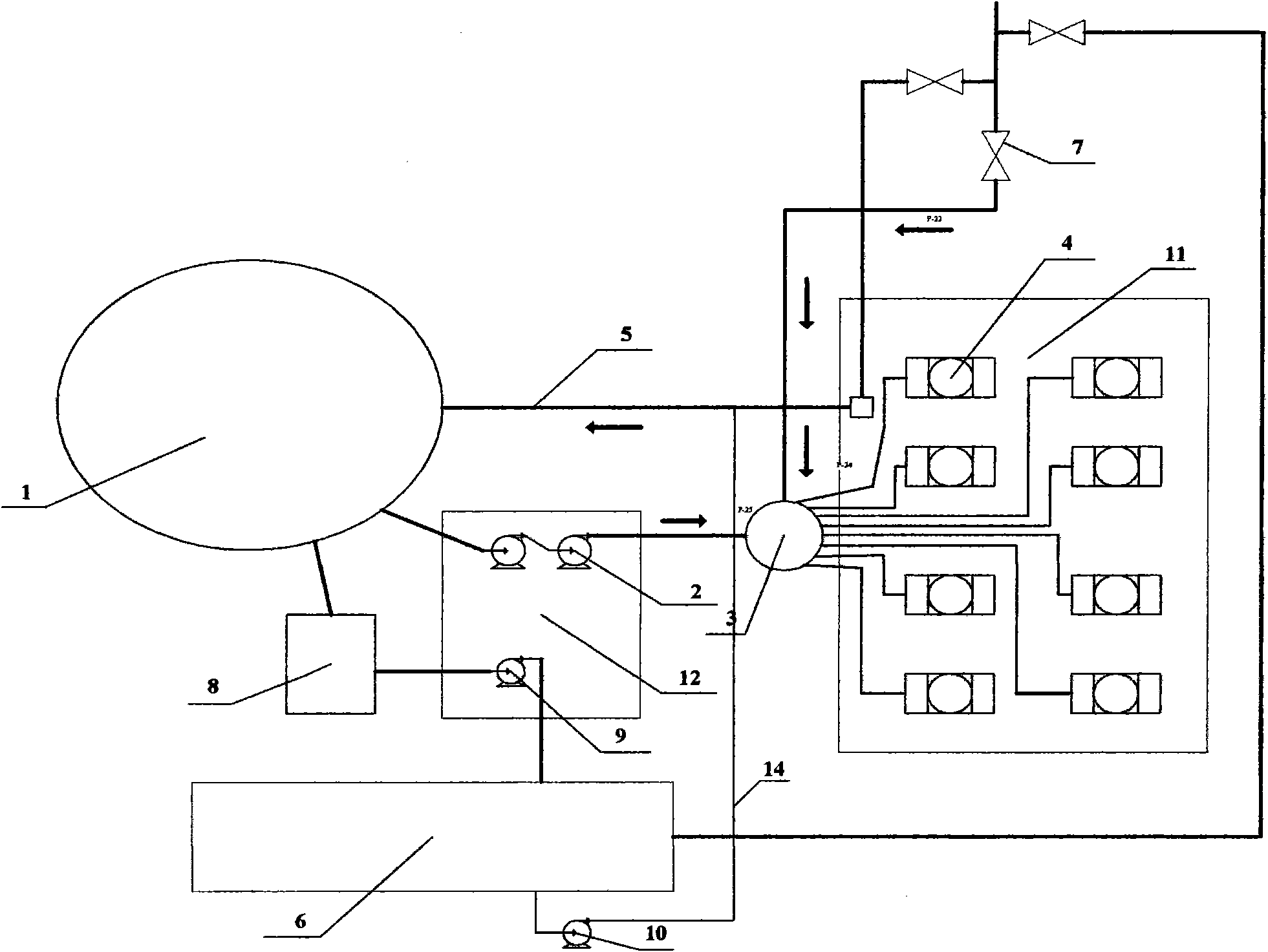

[0032] image 3 Shown in is the production process when the slurry properties are normal. After the pulp reaches the terminal dehydration station, it directly enters the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com