Connecting joint between hollow steel tube concrete column and steel girder and construction method thereof

A technology for steel pipe concrete columns and connection nodes, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of inability to form lateral shrinkage and shear slip, unreasonable load path transfer of nodes, and beam web technology Large hole stress concentration and other problems, to achieve the effect of facilitating mechanized production, improving constructability, and improving seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the implementation and protection scope of the present invention are not limited thereto.

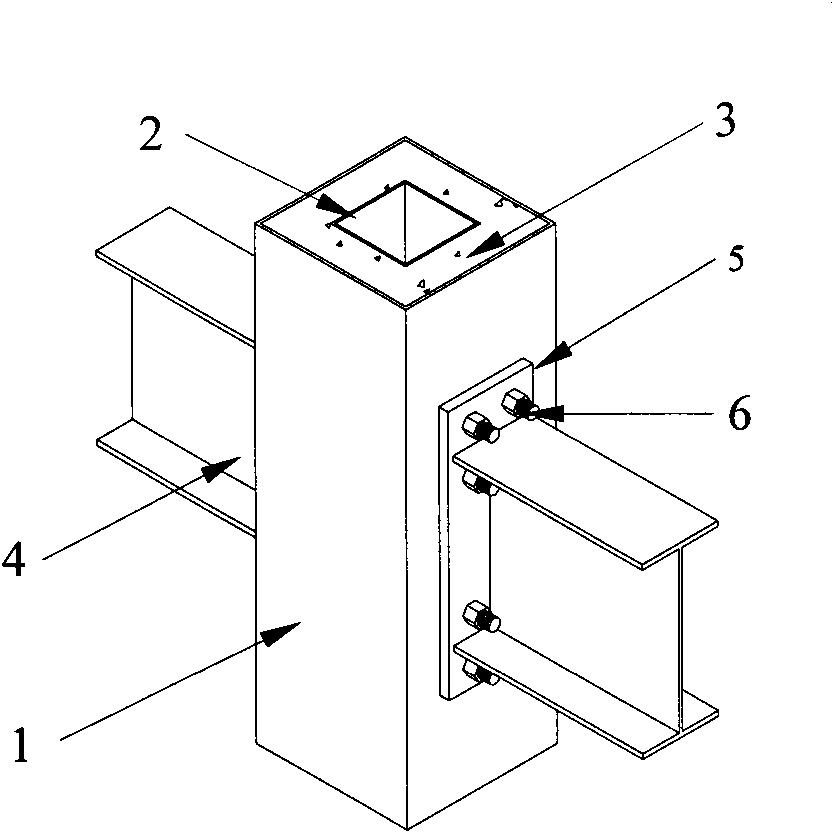

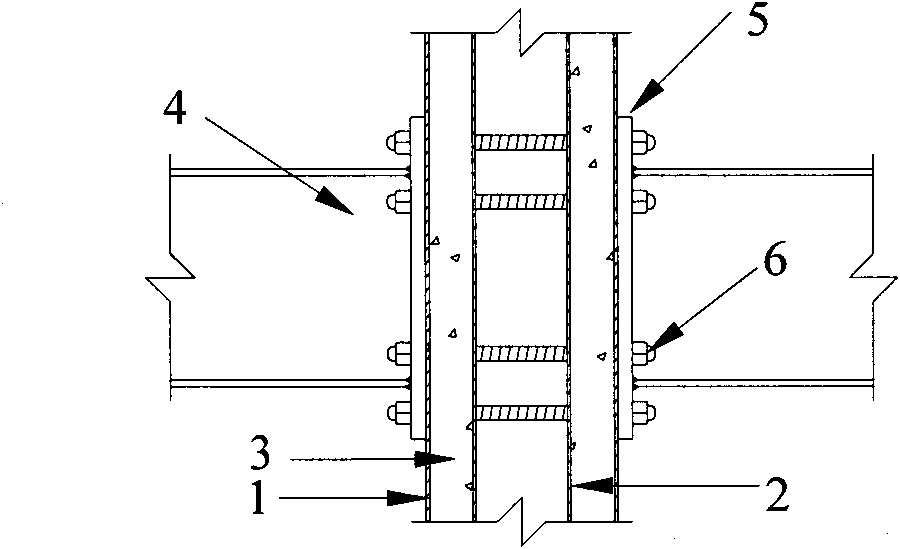

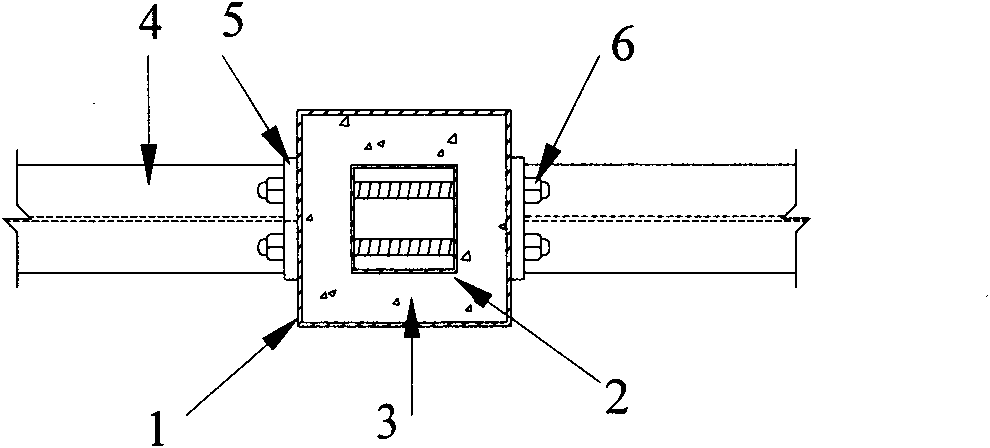

[0032] Such as Figure 1 ~ Figure 3 As shown, the connection node between the hollow concrete-filled steel pipe column and the steel beam includes a hollow concrete-filled steel pipe column, a steel beam 4, an end plate 5 and a high-strength bolt 6 connecting the hollow concrete-filled steel pipe column and the steel beam at the joint, and the end plate 5 Welded at the end of the steel beam 4, bolt holes 7 for the high-strength bolts 6 to pass through are opened on the end plates at the joints and the outer steel pipes of the hollow concrete-filled steel tube columns; the high-strength bolts 6 pass through the end plates 5 The node connection is realized with the bolt hole 7 on the hollow concrete-filled steel tube column. According to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com