Cement concrete pavement and construction method for macroscopic and microscopic texture reconstruction thereof

A technology of cement concrete and construction method, which is applied to pavement details, roads, roads, etc., can solve the problems of poor surface anti-skid performance, large driving noise, limited application, etc., and achieves improved anti-skid performance, reduced driving vibration, and road surface. The effect of improved flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

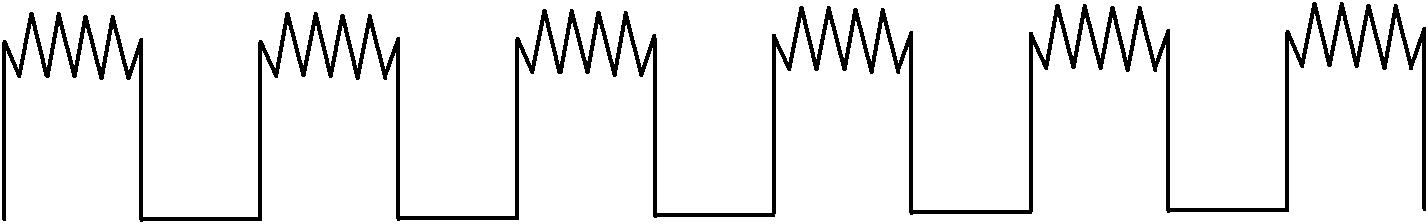

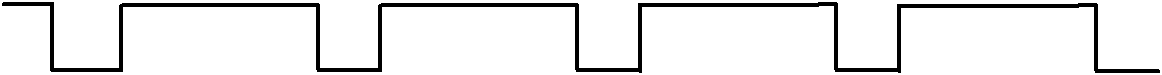

[0020] Depend on figure 1 , figure 2 It can be seen from the comparison that the pavement texture structure obtained after diamond grinding not only has a macro texture, but also forms a jagged micro texture structure between the grooves, thus achieving good results in terms of noise reduction, anti-skid and flatness. .

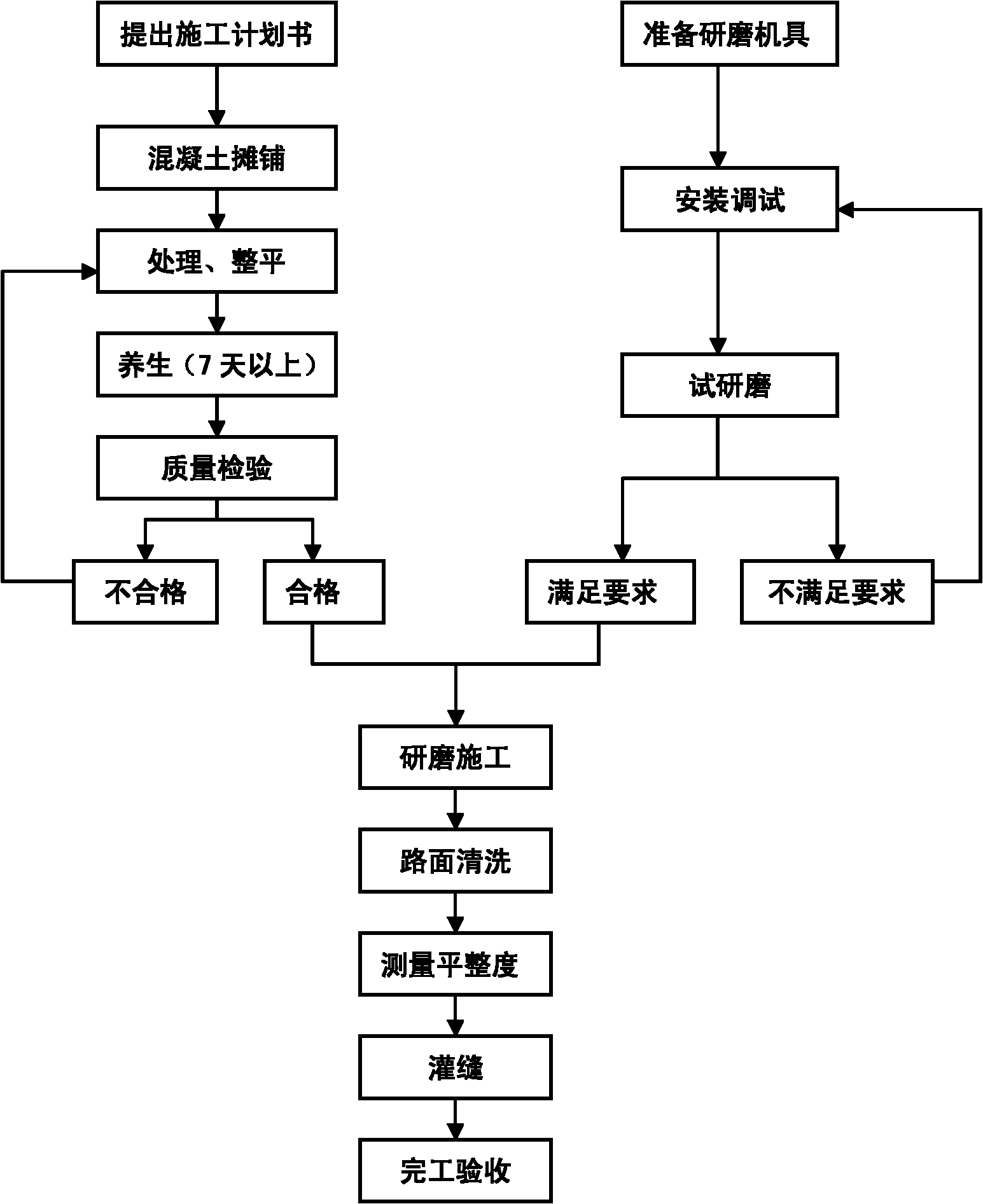

[0021] Include the following steps:

[0022] 1. The contractor proposes a complete construction plan, including: types of grinding machines, types of level control instruments, flatness and skid resistance testing instruments and testing methods, sludge and wastewater collection equipment, grinding methods and scheduled construction progress, Types and specifications of seam repair and caulking materials.

[0023] 2. For new roads, the grinding construction can be organized after the joint construction of the surface layer is completed, after seven days of health preservation and the quality inspection is passed. At the same time, the timing of grinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com