Preparation method of high-magnetic-conductivity low-temperature-sintering Z-shaped hexagonal ferrite material

A hexagonal ferrite, high magnetic permeability technology, applied in the field of electronic materials, can solve the problems of Z-type hexagonal ferrite structure and composition, low densification, low activity of pre-fired materials, etc., to achieve high magnetic Conductivity, compact structure, and reduction in synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

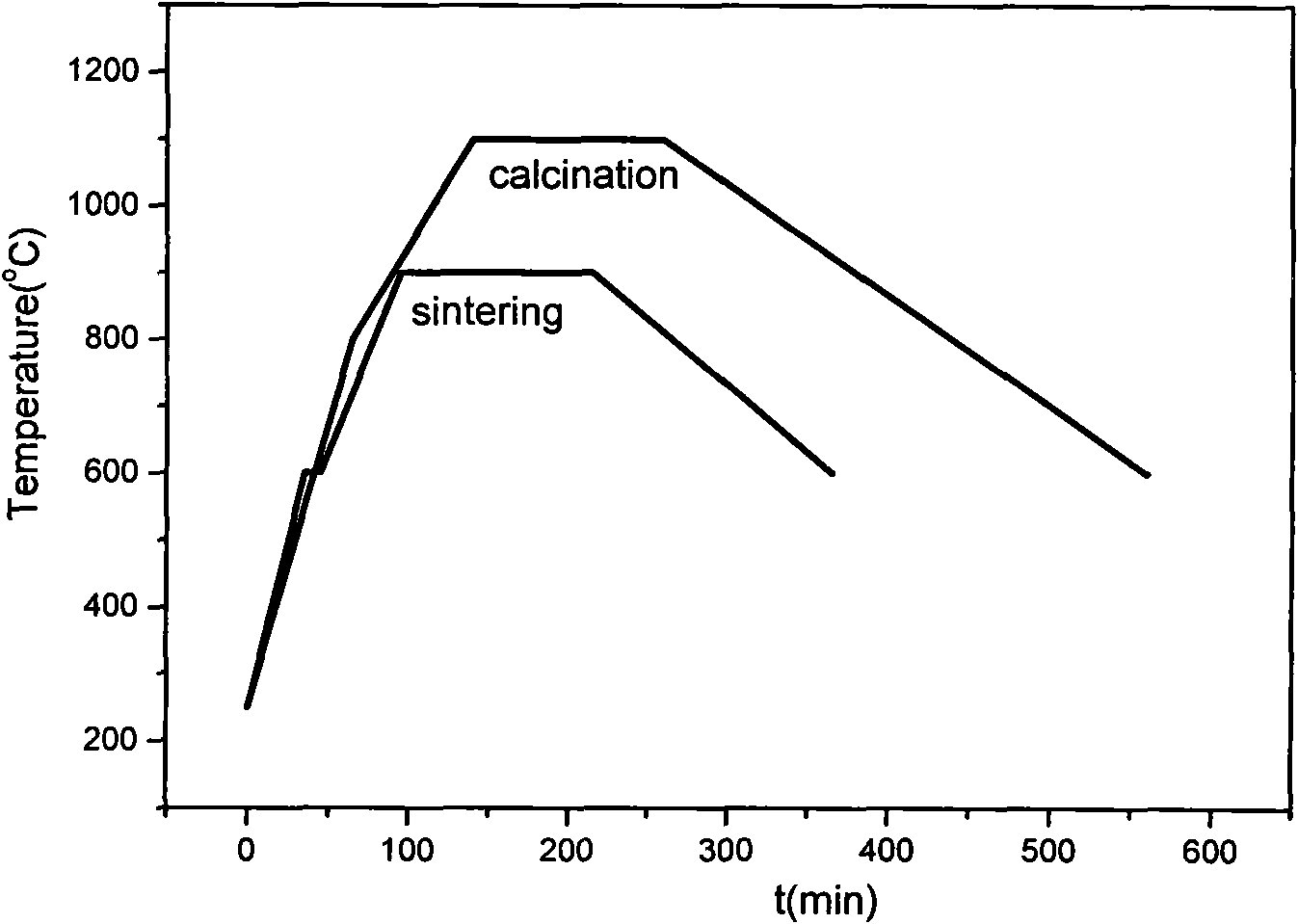

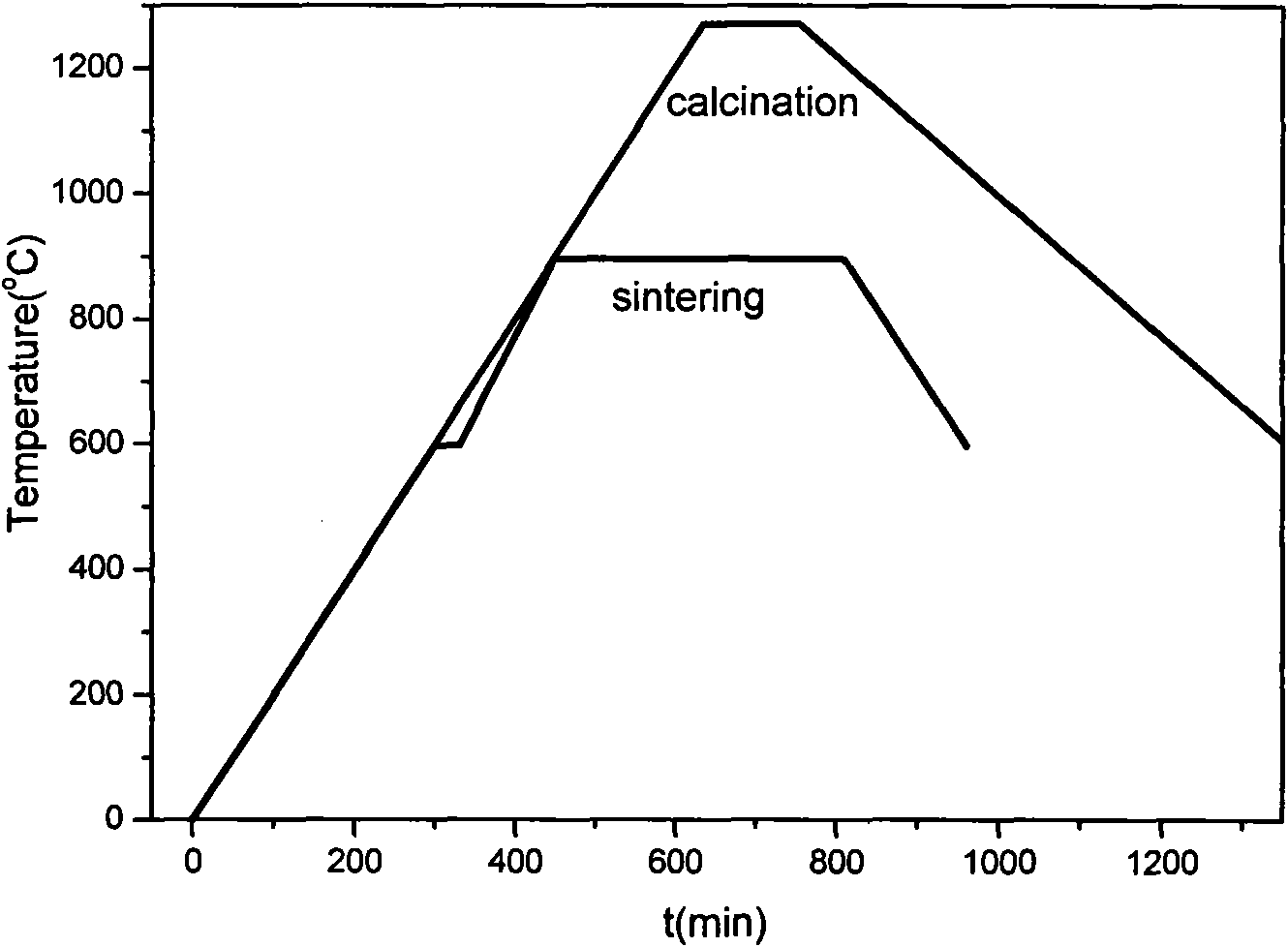

[0023] The present invention will be further described below in conjunction with accompanying drawing:

[0024] The microwave sintered Z-type hexagonal ferrite soft magnetic material proposed by the present invention adopts HAMiLab-C1500 microwave sintering furnace for heat treatment of the material, and the material is mainly made by the following six steps:

[0025] Step 1: According to the chemical formula Ba of Z-type hexagonal ferrite 3 Me 2 Fe 24 o 41 (Me=Co 2+ , Zn 2+ , Mg 2+ , Fe 2+ 、Cu 2+ 、Ni 2+ etc.) to calculate the required raw material BaCO 3 , Fe 2 o 3 、Co 3 o 4 and so on. For example, the preparation composition is Ba 3 co 2 Fe 24 o 41 (Co 2 Z) Material 100g, BaCO is required respectively 3 (99.0%) 23.09g, Co 3 o 4 (Co content 73.02%) 6.23g, consider to use steel ball ball mill during ball milling, adopt the formula of iron deficiency 5wt%, then need Fe 2 o 3 (99.46%) 70.68 g. And the preparation composition is Ba 3 (Zn 0.6 co 0.4 ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com