Six-drop individual section bottle-making machine and pressing and blowing production technology thereof

A determinant bottle-making machine and dripping technology, applied in the field of bottle-making machines, can solve problems affecting the appearance quality of bottles, no overload safety protection, and inability to produce glass bottles, etc., to maintain strength, save raw materials and energy, and operate The effect of increasing the size of the space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

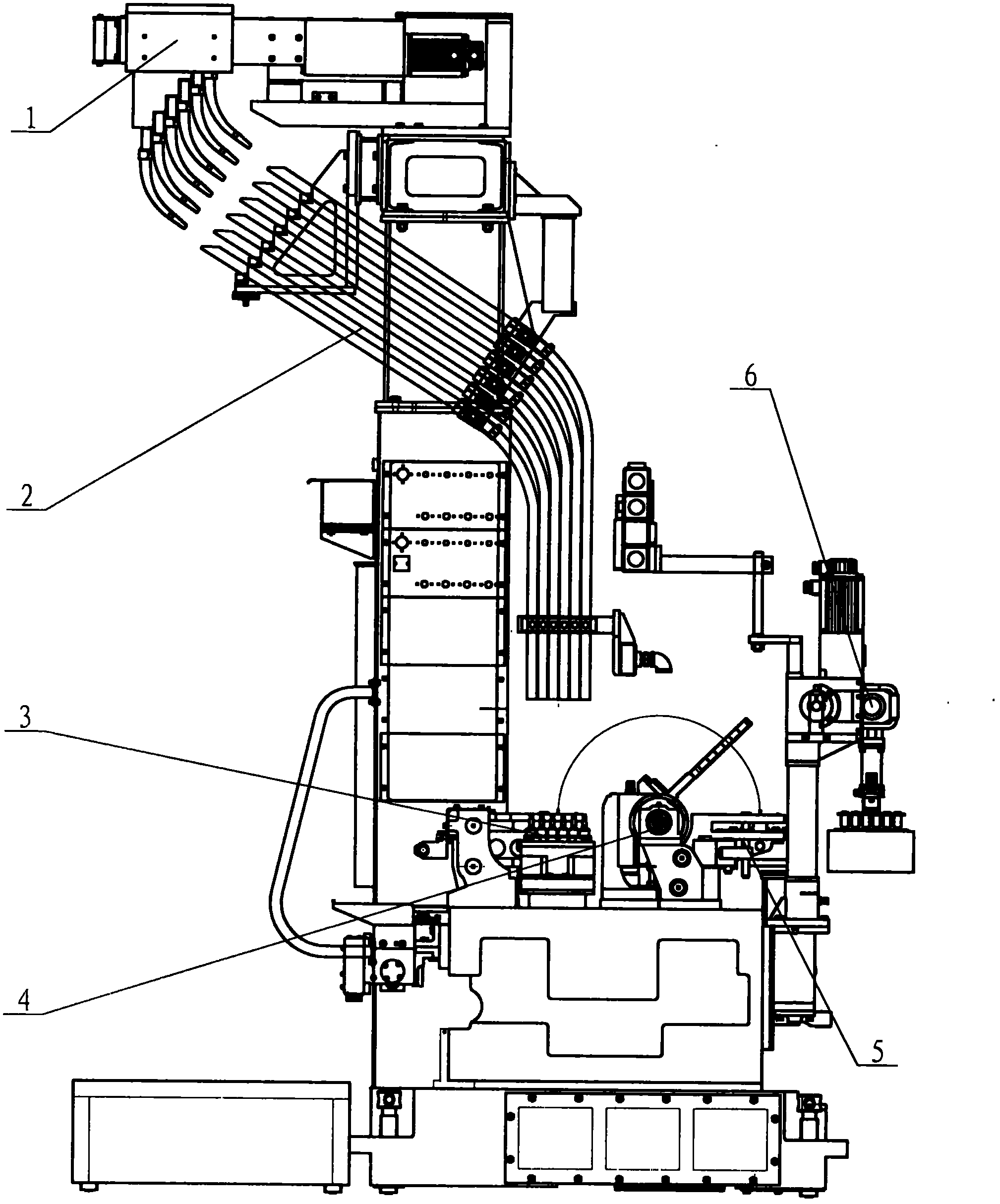

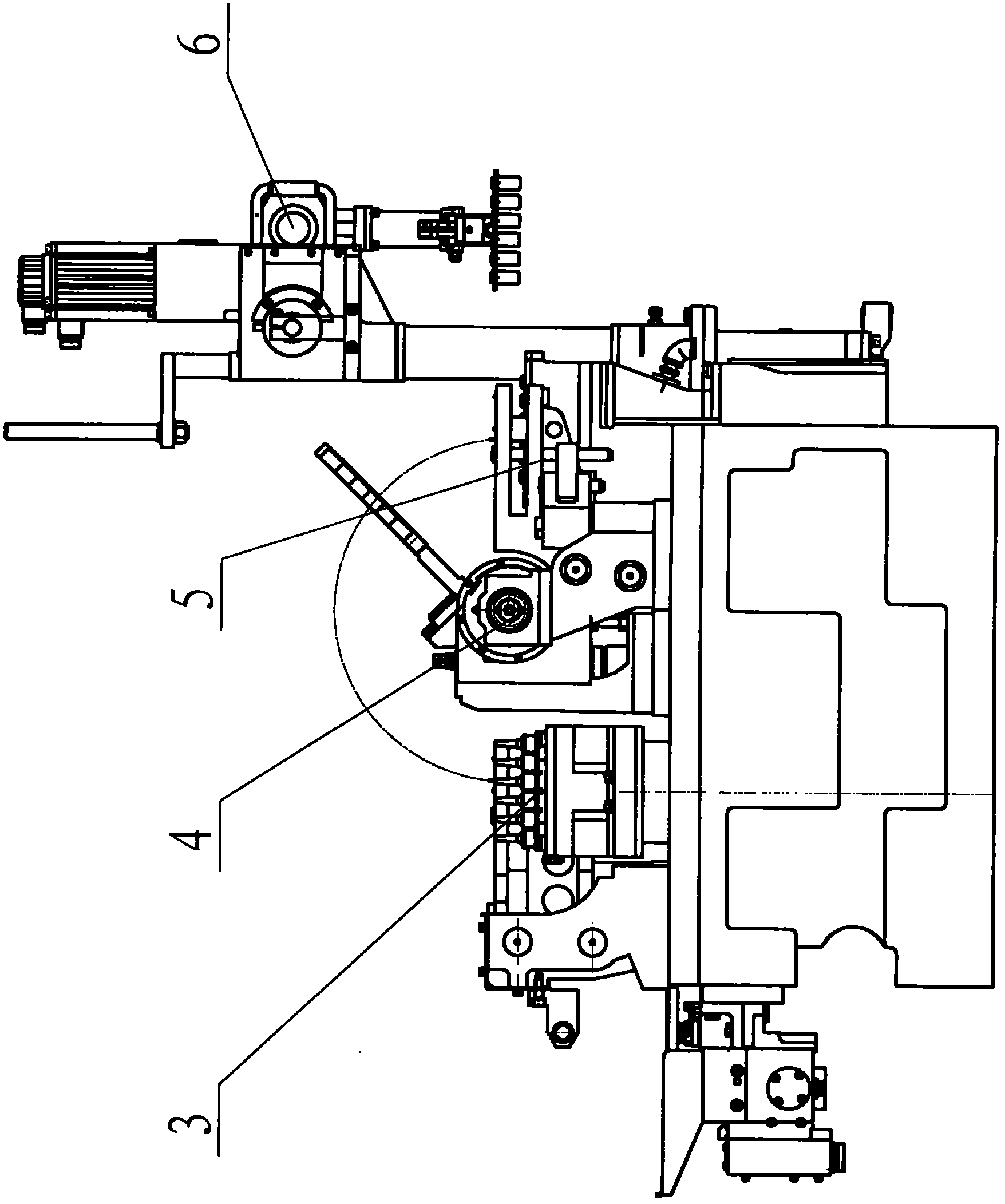

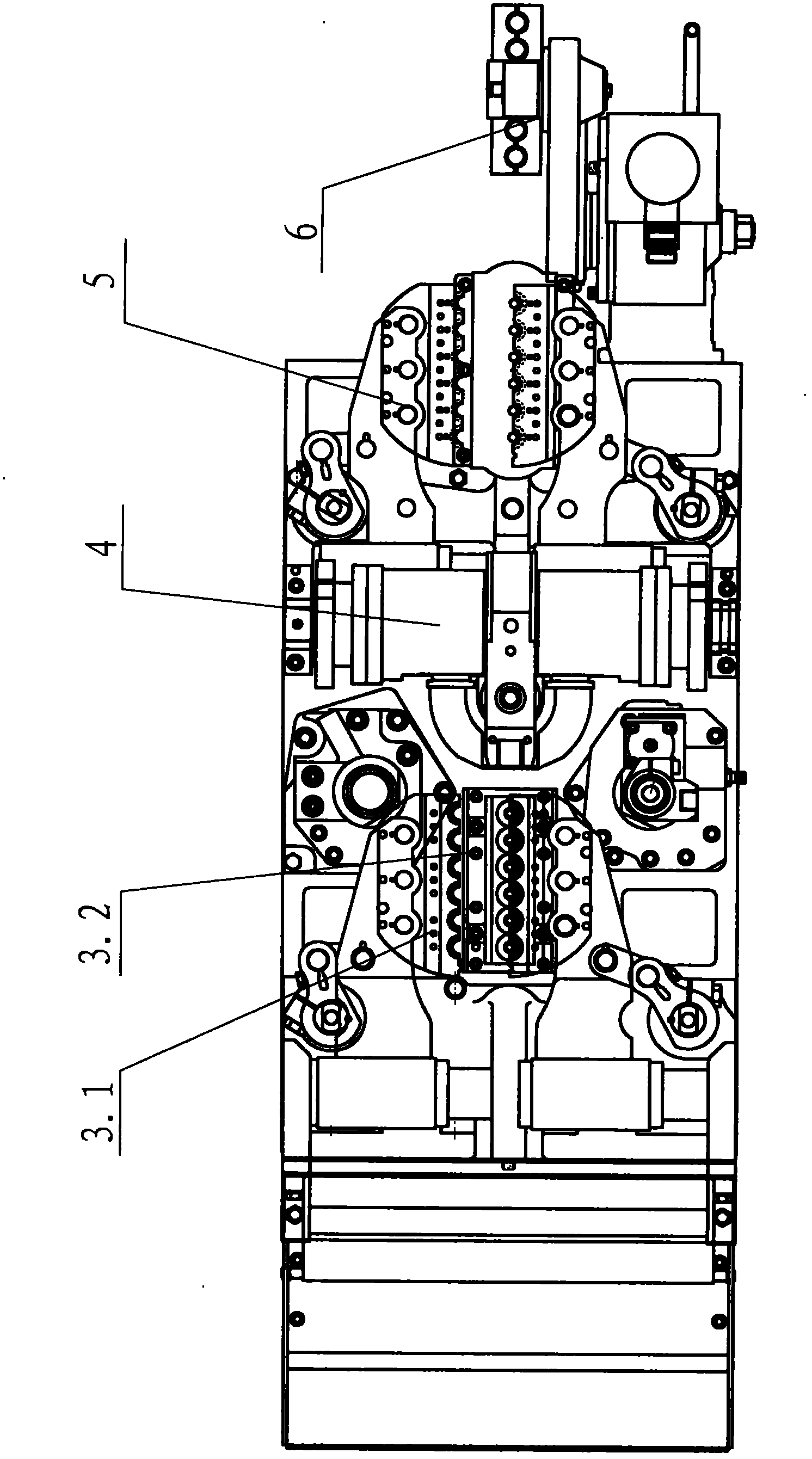

[0066] Such as figure 1 , 2 , A six-drop determinant bottle making machine shown in 3, a crank-link material distribution mechanism 1 is installed on the frame, and the crank-link material distribution mechanism 1 is connected to the initial mold forming mechanism 3 through the flow tube 2. The preliminary model forming mechanism 3, the servo turning mechanism 4, the forming mold forming mechanism 5 and the servo clamp bottle mechanism 6 are sequentially installed on the frame.

[0067] Such as Figure 4 , 5 As shown in , 6, the first servo motor 1.1 is installed on the frame, the output shaft of the first servo motor 1.1 is connected to the worm gear reducer 1.4 through a coupling, and the drive crank 1.8 is arranged on the worm gear reducer 1.4, and the drive crank 1.8 is articulated with the connecting rod One end of 1.7 and the other end of the connecting rod 1.7 are hinged to the distribution assembly module 1.5. The material distribution assembly module 1.5 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com