Method for extracting and dephenolizing coal chemical industry wastewater

A coal chemical wastewater and extraction technology, applied in chemical instruments and methods, extraction water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of low extraction and removal efficiency, high energy consumption of solvent recovery, extraction and removal rate Low and other problems, to achieve the effect of reducing energy consumption of solvent recovery, small amount of solvent, and improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

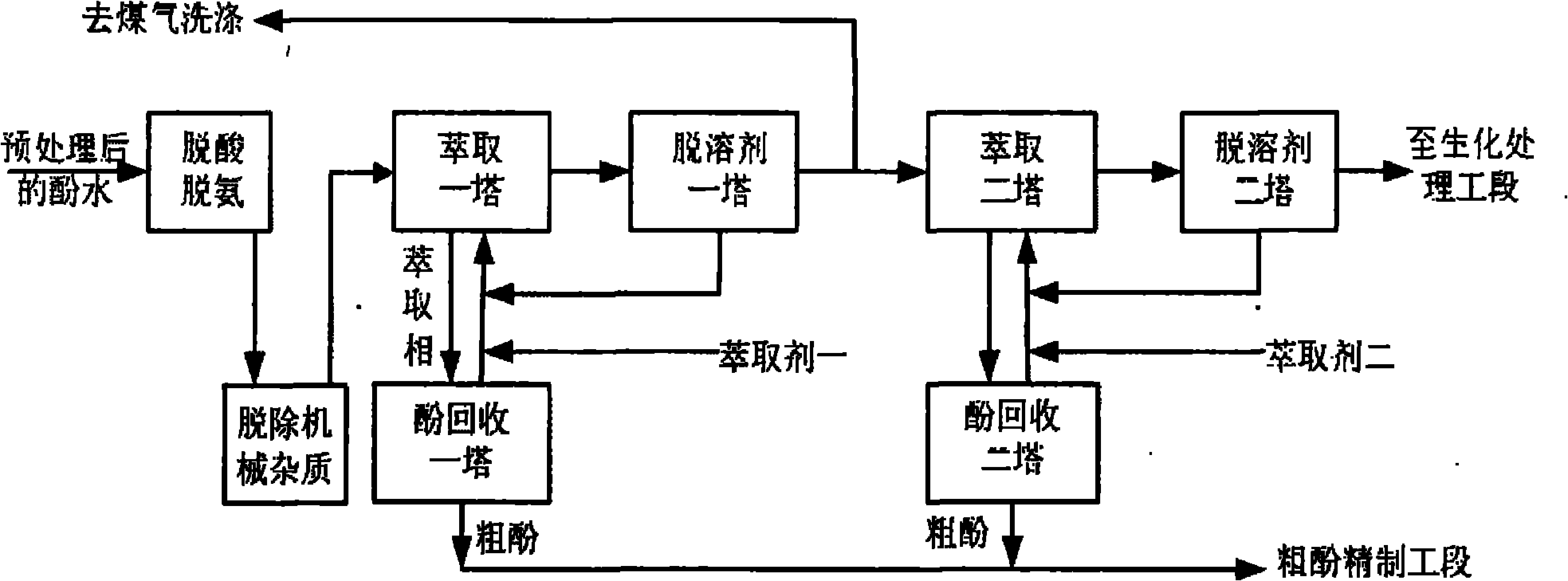

[0033] The high-concentration phenol-containing wastewater extraction and dephenolization equipment consists of deacidification and deamination tower, extraction tower 1, extraction tower 2, solvent recovery tower 1, solvent recovery tower 2, phenol recovery tower 1, phenol recovery tower 2 and auxiliary heating and heat exchange , Remove mechanical impurities equipment, pumping system. The extraction tower is a packed tower with honeycomb grid structured packing. The deacidification and deamination tower and the solvent recovery tower are plate towers, which are heated by high-pressure steam.

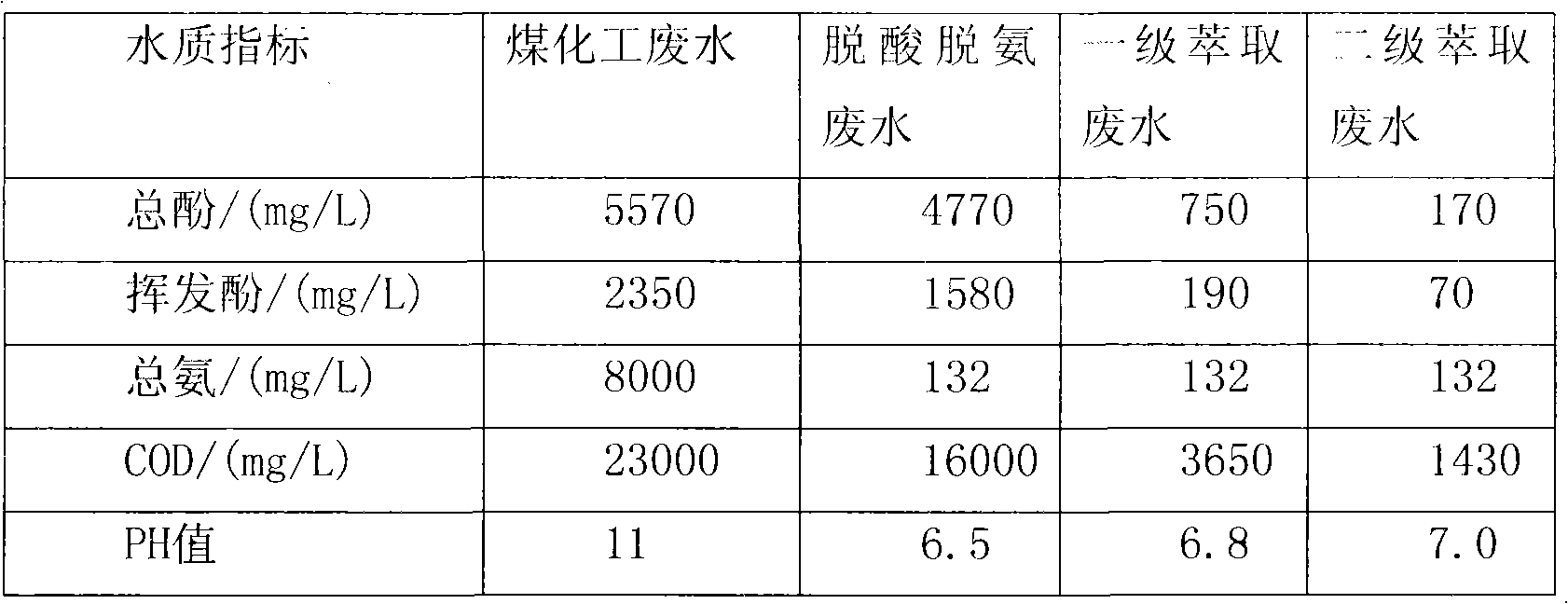

[0034] The process flow of extraction and dephenolization of high-concentration phenol-containing wastewater is as follows: figure 1shown. The high-concentration phenol-containing wastewater produced by Lurgi furnace gasification is pretreated by gravity sedimentation to remove oil, and first enters the stripping, deacidification and deamination tower. The stripping tower is heated ...

example 2

[0038] The water treatment equipment is as described in Example 1. The extraction and dephenolization process of phenolic wastewater is as follows: figure 1 shown.

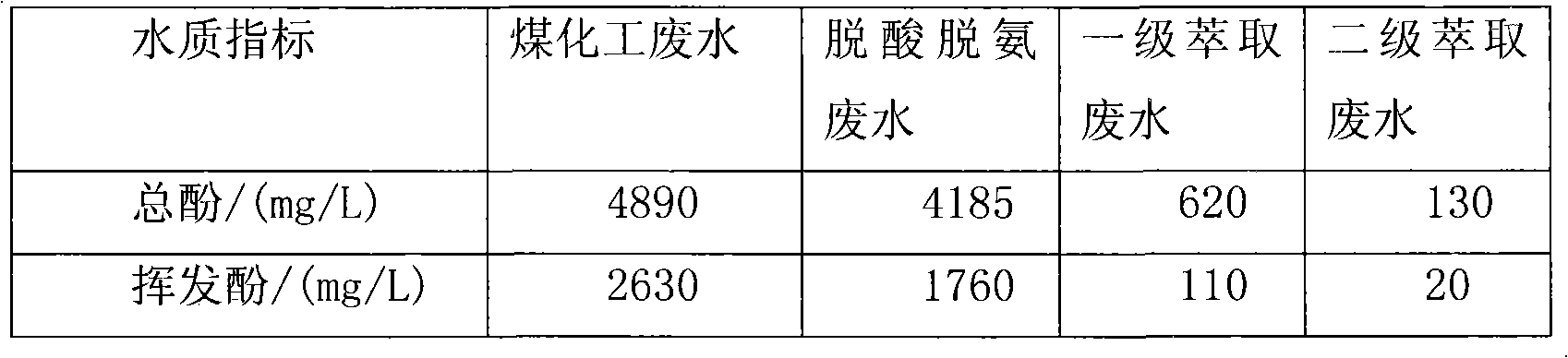

[0039] The high-concentration phenol-containing wastewater produced by Lurgi furnace gasification is pretreated by gravity sedimentation to remove oil, and first enters the stripping, deacidification and deamination tower. The stripping tower is heated by steam, the temperature of the tower kettle is controlled at 145-155°C, the pressure of the tower kettle is 0.3-0.4MP, and the deacidification and deammoniation water flows out from the bottom of the tower. After removing mechanical impurities, it is cooled by heat exchanger To 45 ~ 50 ℃, the pH value is about 6. Then, the phenolic water is pumped into the top of the first extraction tower and contacted with the extractant diisopropyl ether countercurrently to perform primary extraction and dephenolization. The volume ratio of the extractant and waste water is 1...

example 3

[0044] The water treatment equipment is as described in Example 1. The extraction and dephenolization process of phenolic wastewater is as follows: figure 1 shown.

[0045] The high-concentration phenol-containing wastewater produced by the Lurgi furnace is pretreated by gravity sedimentation to remove oil, and then first enters the stripping, deacidification and deamination tower. The stripping tower is heated by steam, the temperature of the tower tank is controlled at 145-155°C, and the pressure of the tower tank is 0.3-0.4MP. The deamination and deacidification water flows out from the bottom of the tower. After removing mechanical impurities, the heat is exchanged by the heat exchanger. Cool to 45 ~ 50 ℃, pH value is about 7.5. Then, the phenolic water is pumped into the top of the first extraction tower and contacted with the extractant diisopropyl ether countercurrently to perform primary extraction and dephenolization. The volume ratio of the extractant and waste wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com