Device for concentrating and separating colloid in underground water

A separation device and groundwater technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of poor treatment effect, unsatisfactory treatment effect and low selectivity, etc. Achieve the effects of easy promotion, large-scale promotion and application, and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

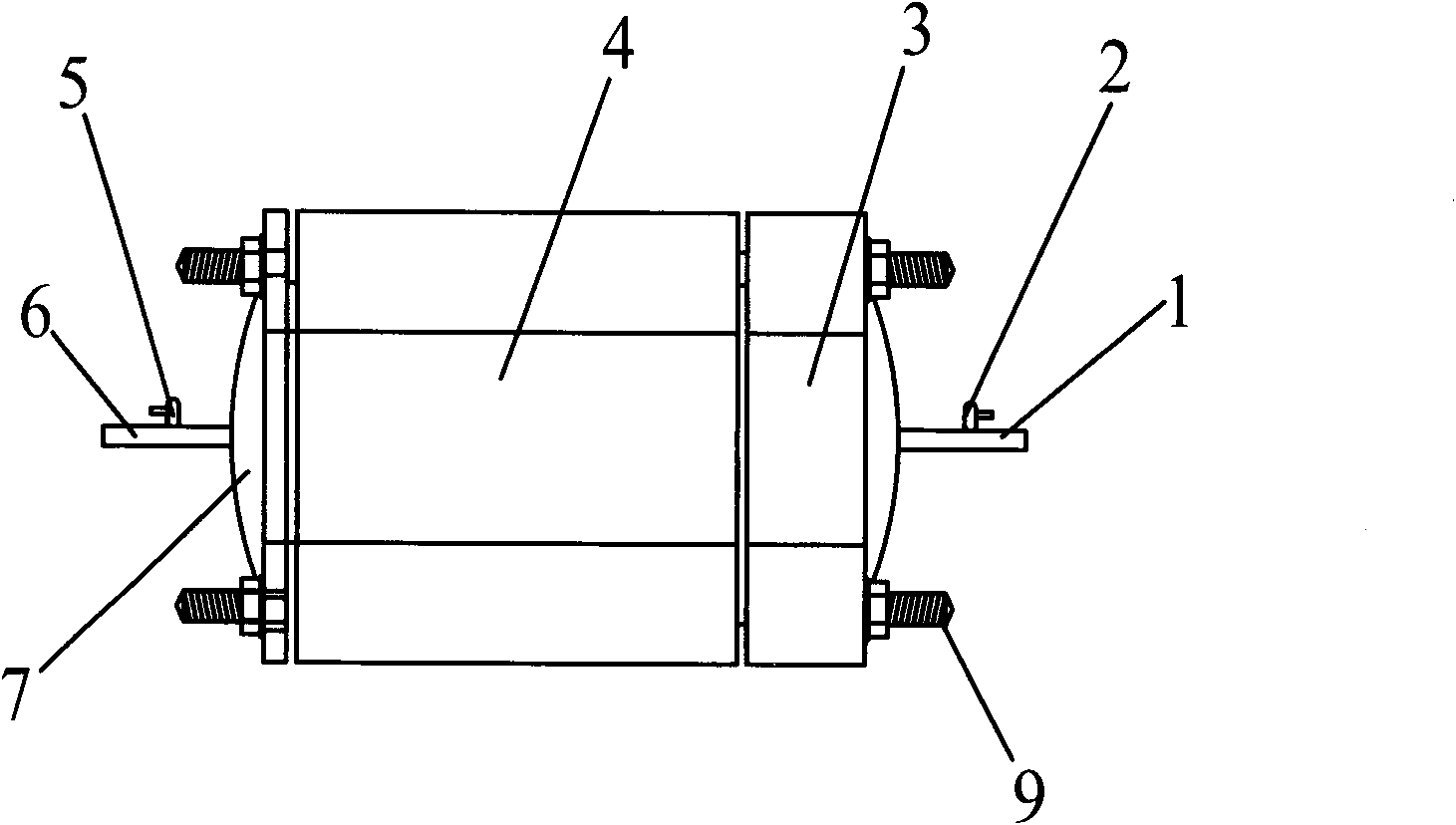

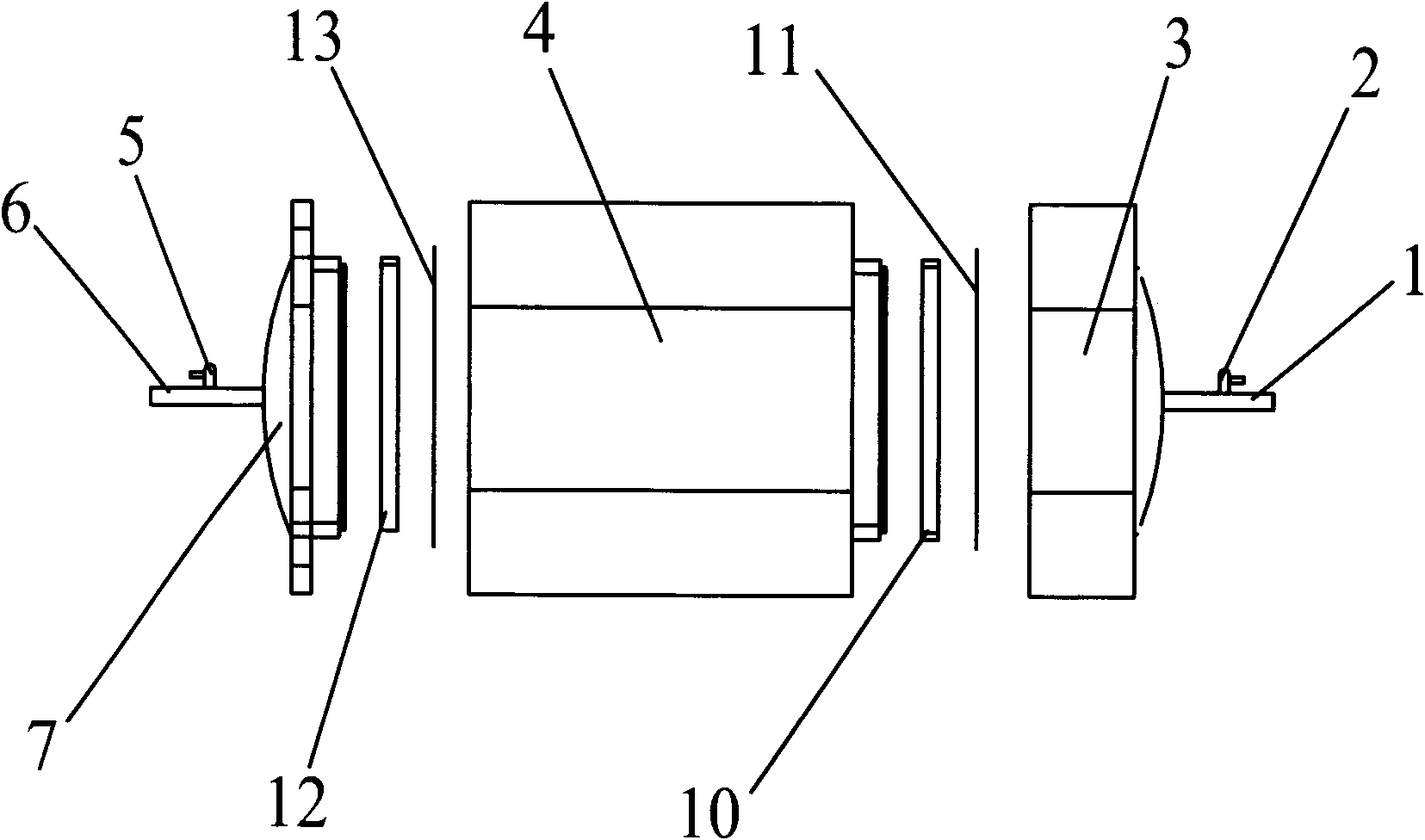

[0053] Such as figure 1 and figure 2 A kind of device that concentrates and separates the colloid in groundwater shown, comprises left end sealing cover 7, right end sealing cover 3 and is positioned at the separating device between left end sealing cover 7 and right end sealing cover 3, described left end sealing cover 7, separating device and The right-end sealing cover 3 is sequentially connected by a fastening screw 9, the side of the right-end sealing cover 3 away from the separation device is provided with a liquid inlet 1, and the side of the left-end sealing cover 7 far away from the separation device is provided with a liquid discharge port 6. A sealing ring 10 is arranged between the right sealing cover 3 and the separation device, and a filter membrane 11 is arranged on the side of the sealing ring 10 close to the right sealing cover 3, and the left sealing cover 7 and the separating device A sealing ring two 12 is arranged between the devices, and a filter membra...

Embodiment 2

[0057] Such as Figure 5 A kind of device that concentrates and separates the colloid in groundwater shown, comprises left end sealing cover 7, right end sealing cover 3 and is positioned at the separating device between left end sealing cover 7 and right end sealing cover 3, described left end sealing cover 7, separating device and The right-end sealing cover 3 is sequentially connected by a fastening screw 9, the side of the right-end sealing cover 3 away from the separation device is provided with a liquid inlet 1, and the side of the left-end sealing cover 7 far away from the separation device is provided with a liquid discharge port 6. A sealing ring 10 is arranged between the right sealing cover 3 and the separation device, and a filter membrane 11 is arranged on the side of the sealing ring 10 close to the right sealing cover 3, and the left sealing cover 7 and the separating device A sealing ring two 12 is arranged between the devices, and a filter membrane two 13 is a...

Embodiment 3

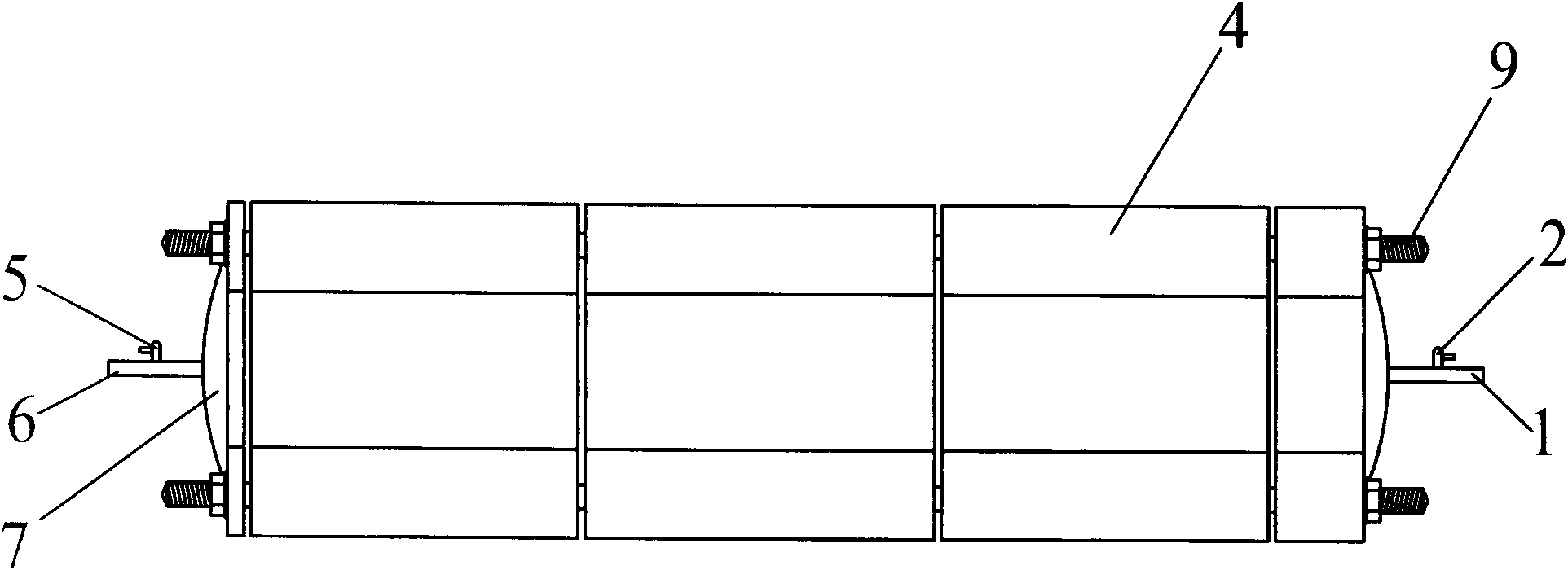

[0062] Such as image 3 and Figure 4 A kind of device that concentrates and separates the colloid in groundwater shown, comprises left end sealing cover 7, right end sealing cover 3 and is positioned at the separating device between left end sealing cover 7 and right end sealing cover 3, described left end sealing cover 7, separating device and The right-end sealing cover 3 is sequentially connected by a fastening screw 9, the side of the right-end sealing cover 3 away from the separation device is provided with a liquid inlet 1, and the side of the left-end sealing cover 7 far away from the separation device is provided with a liquid discharge port 6. A sealing ring 10 is arranged between the right sealing cover 3 and the separation device, and a filter membrane 11 is arranged on the side of the sealing ring 10 close to the right sealing cover 3, and the left sealing cover 7 and the separating device A sealing ring two 12 is arranged between the devices, and a filter membra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com