Physical gas-phase deposition chamber gastightness detecting method

A technology of physical vapor deposition and air tightness detection, which is applied in the direction of using liquid/vacuum degree to measure liquid tightness, and using electrical devices to test fluid tightness, etc. It can solve the changes in PVD deposition chamber environment and production conditions, etc. Problems, to achieve the effect of reducing quantity and reducing consumption

Inactive Publication Date: 2009-06-17

SEMICON MFG INT (SHANGHAI) CORP

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] Although the above method can be used to detect abnormal operation of the PVD deposition chamber in time, after the gas discharge in the vacuum is excited, it is easy to cause changes in the environment in the PVD deposition chamber, that is, it is easy to cause changes in production conditions.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

no. 1 example

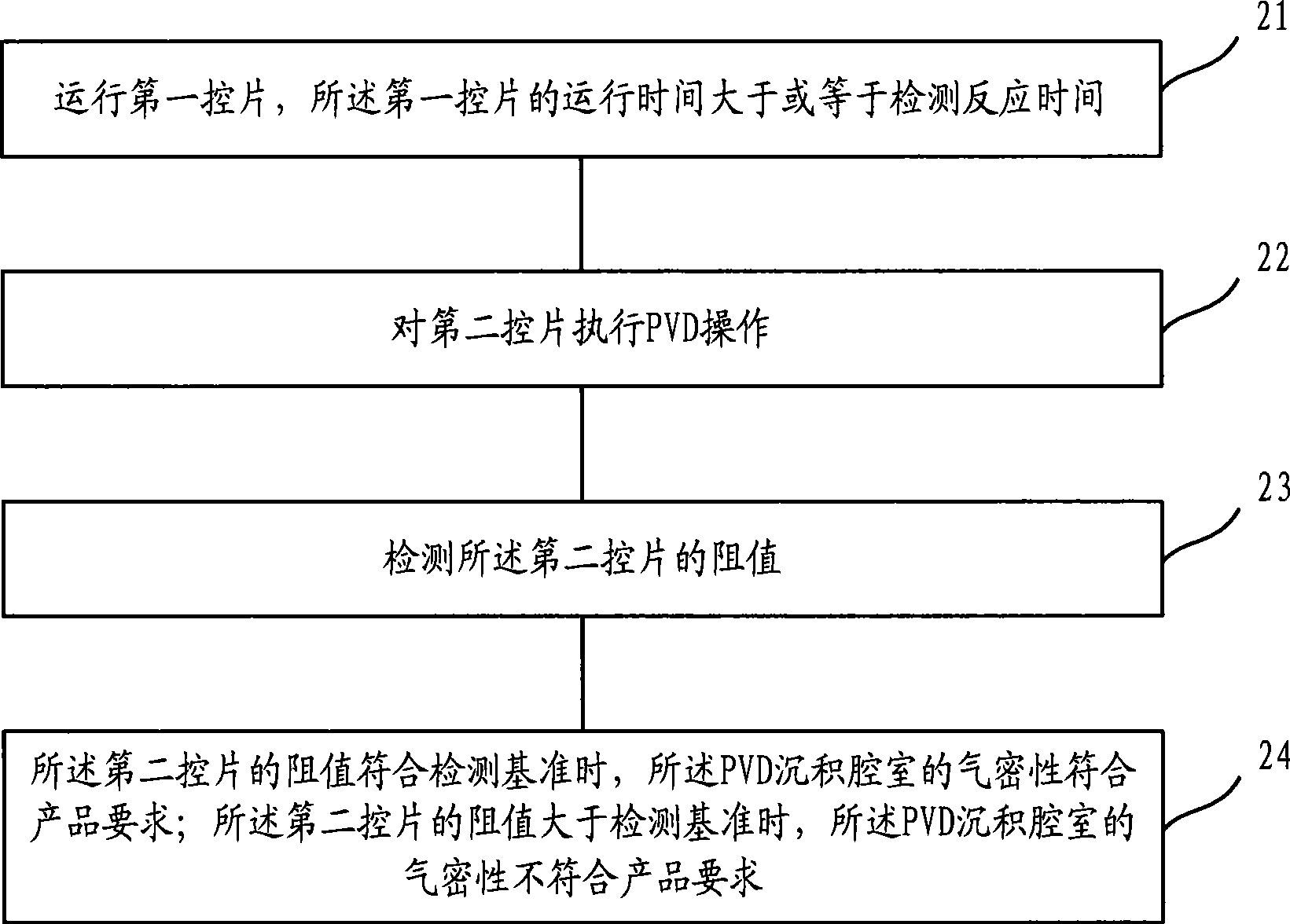

[0041] Such as figure 2 As shown, as the first embodiment of the present invention, the specific steps of applying the method provided by the present invention to detect the airtightness of the PVD deposition chamber include:

[0042] Step 21: Run the first control panel, the running time of the first control panel is greater than or equal to the detection reaction time.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

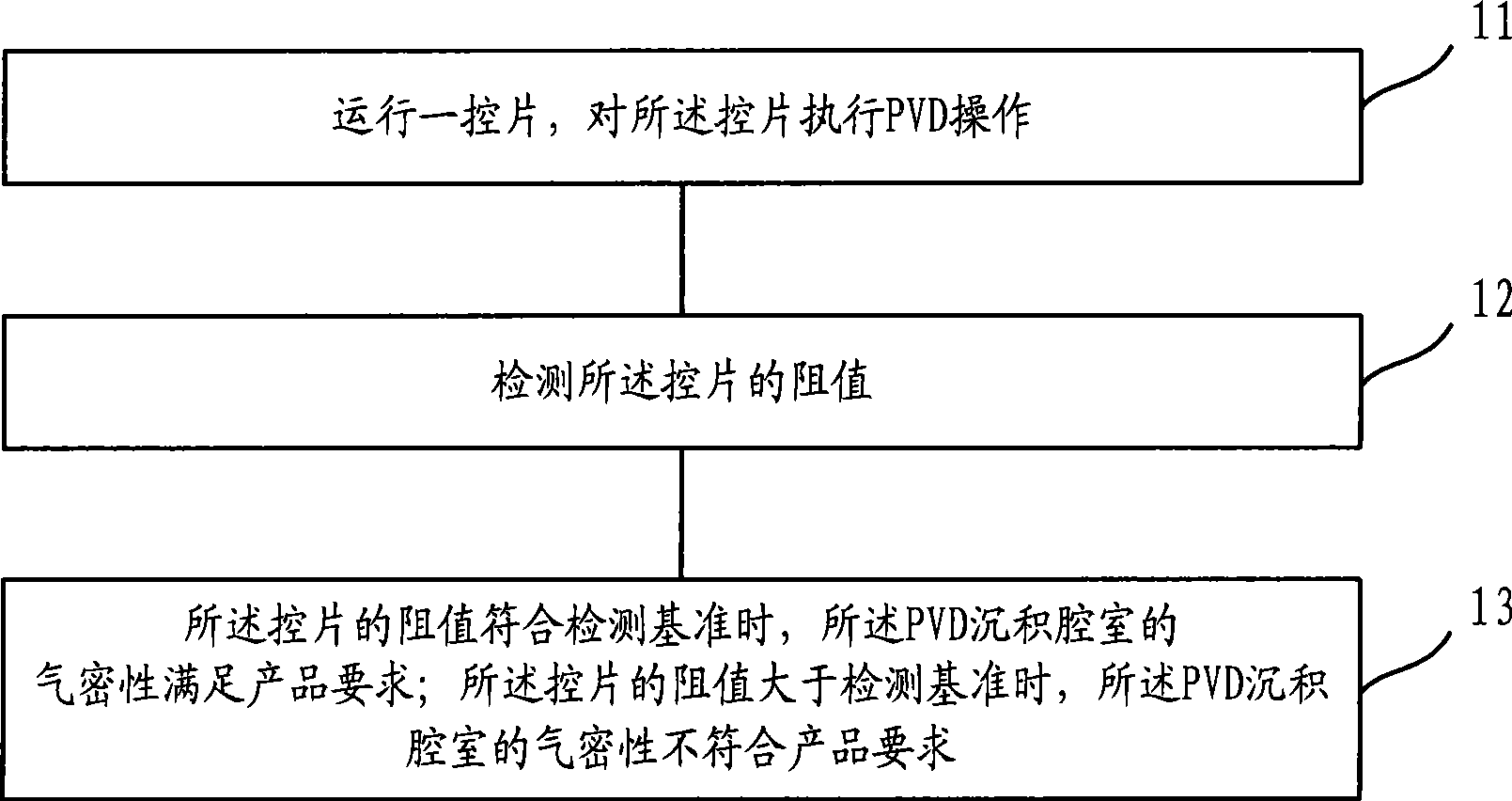

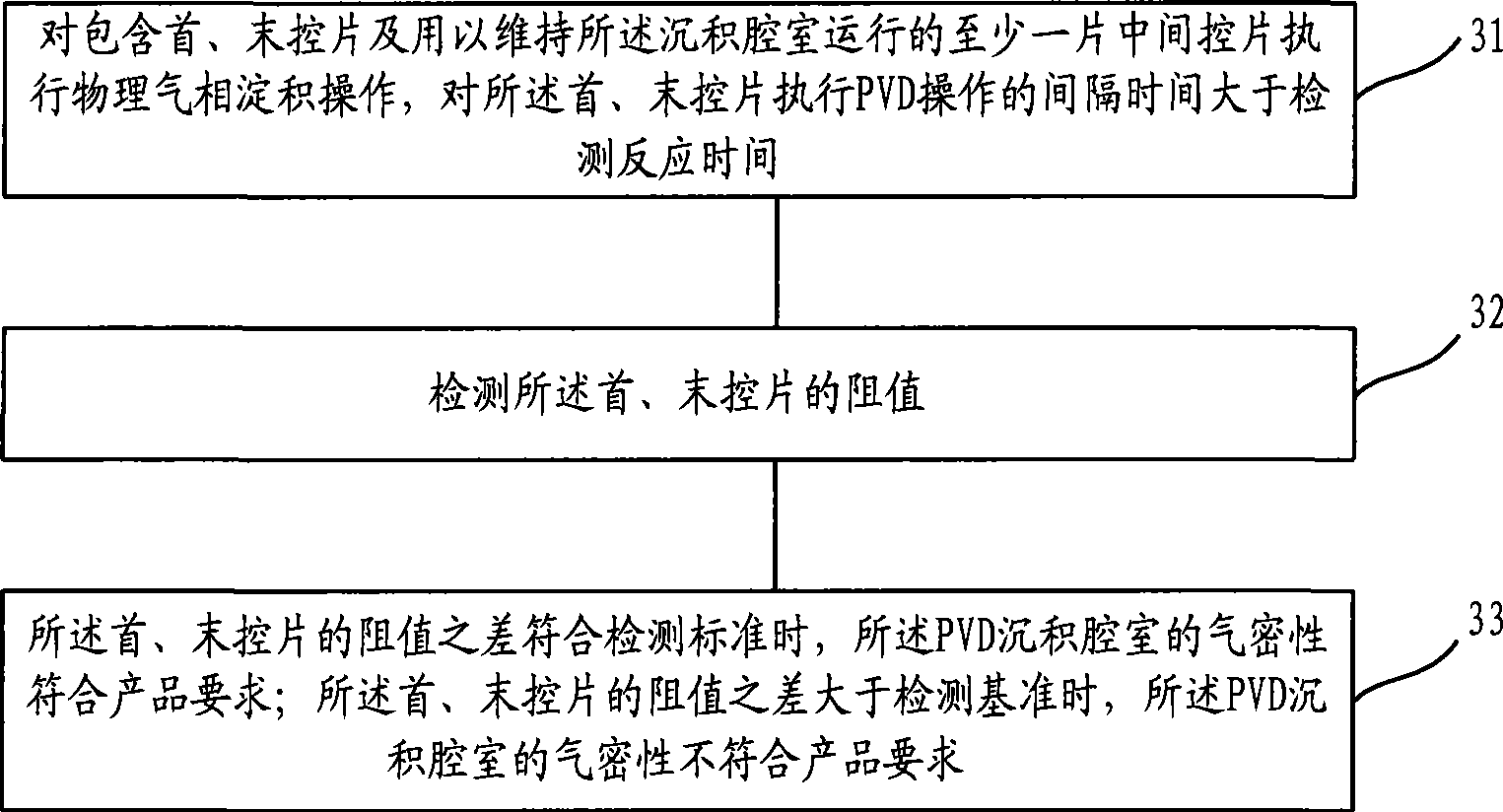

The invention relates to a method for detecting the air tightness of a physical vapor deposition and sedimentation cavity, which comprises the following steps: a first control wafer runs, and the running time of the first control wafer is more than or equal to detecting reaction time; physical vapor deposition is carried out on a second control wafer; the resistance value of the second control wafer is detected; when the resistance value of the second control wafer conforms to a detecting standard, the air tightness of the physical vapor deposition and sedimentation cavity meets product requirements; when the resistance value of the second control wafer is more than the detecting standard, the air tightness of the physical vapor deposition and sedimentation cavity does not meet the product requirements. The method can timely detect abnormal situations of the physical vapor deposition and sedimentation cavity after running, thus being good for shooting trouble, so as to reduce the quantity of production when the physical vapor deposition and sedimentation cavity is at abnormal state, while not changing the environment in the physical vapor deposition and sedimentation cavity.

Description

technical field [0001] The invention relates to the technical field of semiconductor manufacturing, in particular to a method for detecting air tightness of a physical vapor deposition deposition chamber. Background technique [0002] Currently, traditional metallization processes used in semiconductor manufacturing, including evaporation, sputtering, and electroplating, are all subsumed into physical vapor deposition (PVD). In order to maintain the purity of the deposited film, the vacuum in the PVD deposition chamber is an important parameter in the PVD process. When empty, the vacuum in the PVD deposition chamber is typically 10 -9 T; during operation, the vacuum in the PVD deposition chamber is typically 10 -2 T; however, usually when the PVD deposition chamber starts to operate or after a period of operation, such as 24 hours, the operation of the PVD deposition chamber needs to be detected. [0003] The air tightness test of the PVD deposition chamber is an importan...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M3/40G01M3/02

Inventor 聂佳相苏娜胡宇慧

Owner SEMICON MFG INT (SHANGHAI) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com