Driving device for fan-shaped pouring ladle

A technology of driving device and pouring ladle, applied in the field of driving device, can solve the problems of easy wear of constant velocity plate and support arm roller, uneven wall thickness of ductile iron pipe, inability of molten iron to be constant velocity, etc., so as to avoid economic loss and ensure pouring Quality, the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the above objects, features and beneficial effects of the present invention more obvious and easy to understand, the technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the drawings and specific implementation manners in the embodiments of the present invention.

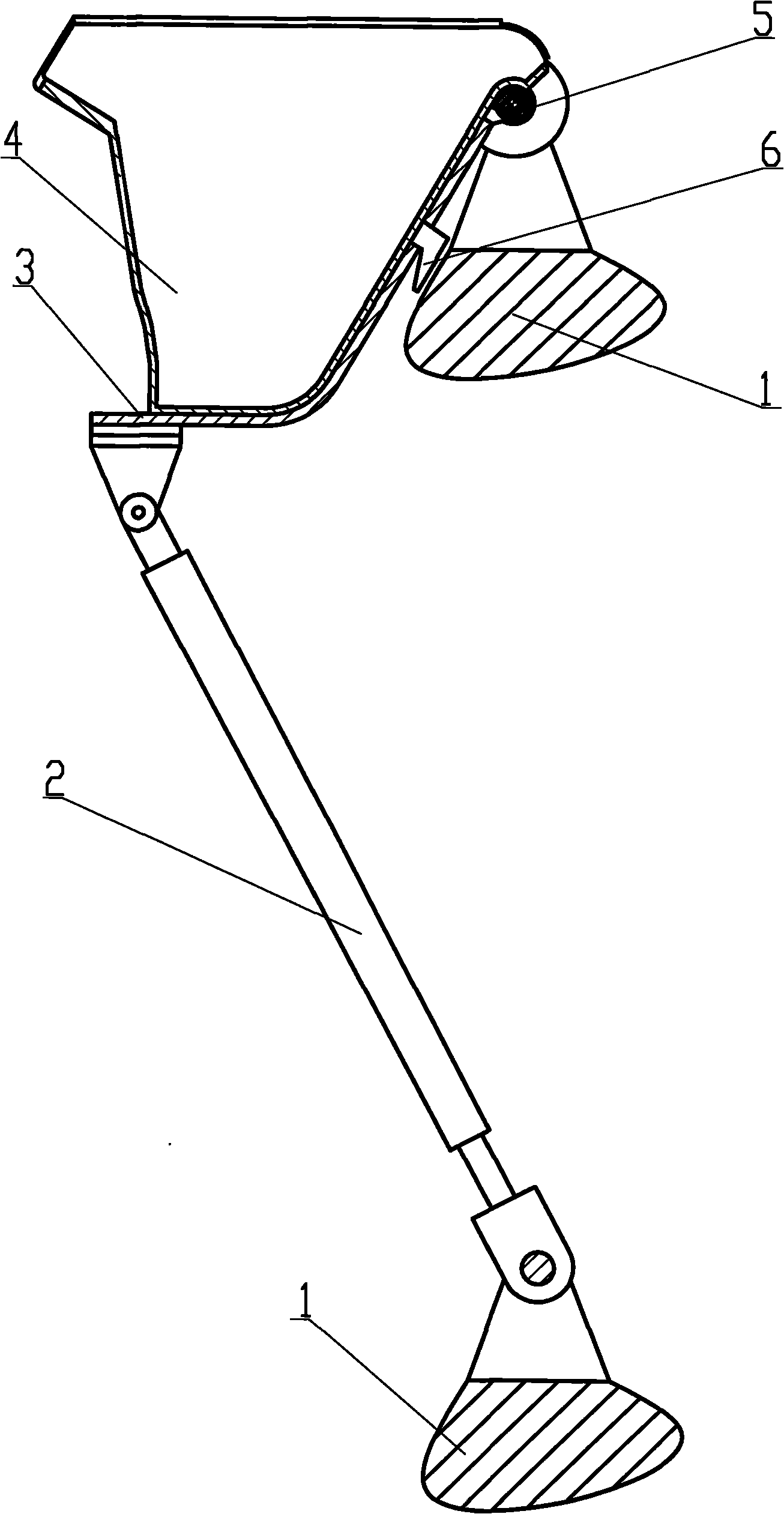

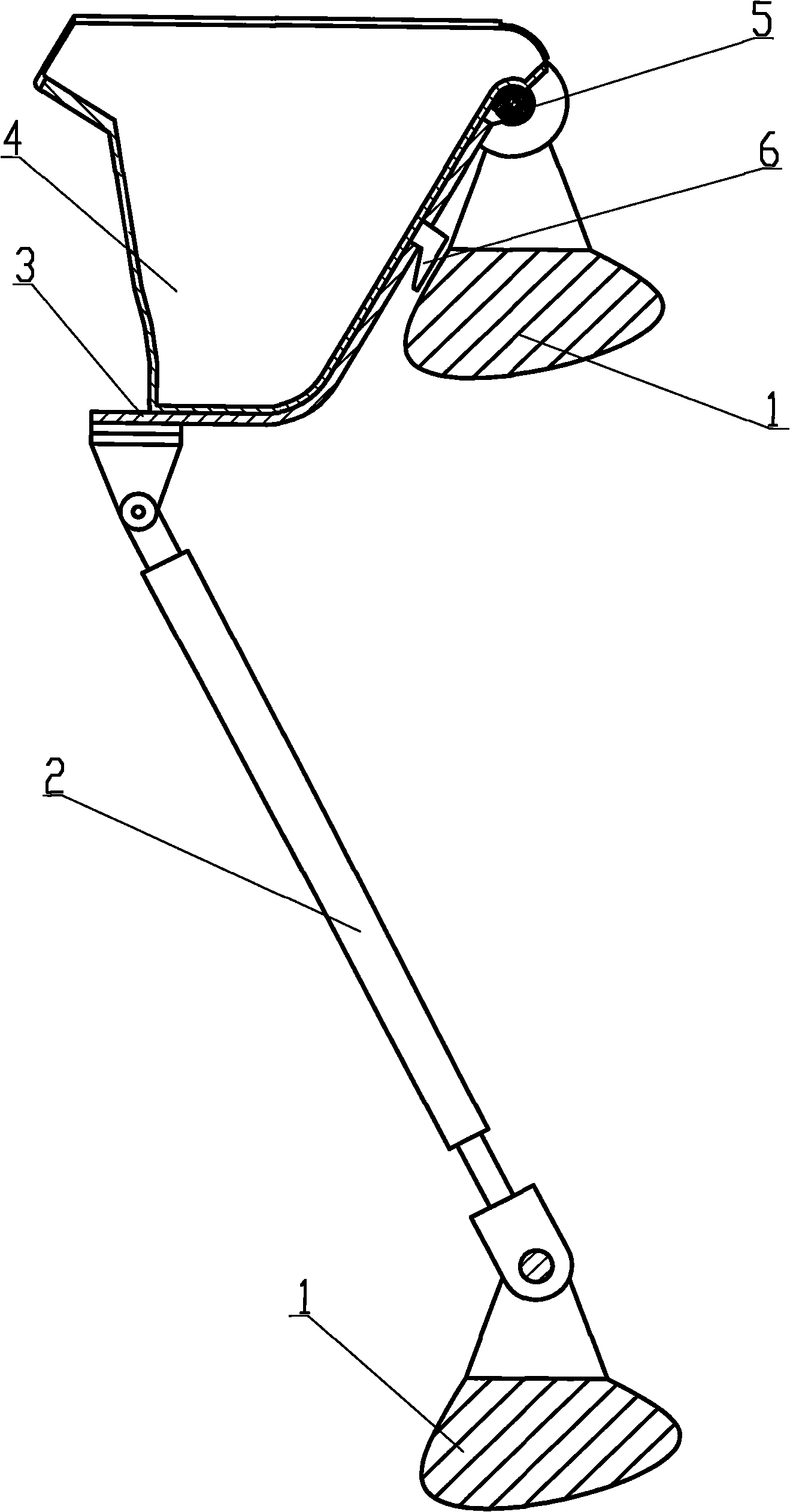

[0011] like figure 1 The key improvement of the fan-shaped ladle driving device shown is that it includes a bracket 3 fixedly installed at the bottom of the fan-shaped ladle 4 and hydraulic cylinders 2 symmetrically arranged on both sides of the fan-shaped ladle; The rotating shaft 5 is fixedly installed on the top of the casting frame 1, and an angular displacement sensor and an angular velocity sensor are arranged on the rotating shaft 5, and the signal output ends of the angular displacement sensor and the angular velocity sensor are connected with the hydraulic station control circuit of the driving hydraulic cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com