Method for eliminating edge fault of aluminium killed steel with low manganese-sulfur ratio and low carbon

A low-carbon aluminum-killed steel and manganese-sulfur ratio technology is applied in the field of steel rolling to achieve the effect of reducing the production cost and the difficulty of smelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific implementation examples

[0019] The rolling of low-carbon aluminum-killed steel SPHC (a low-carbon aluminum-killed steel named after a Japanese brand name) was carried out on the 2250mm hot continuous rolling production line of Shougang Qiangang by using the method and control means involved in the present invention. The size of the slab is 230×1250×9000mm, the rolling specification of No. 1~9 is 3.0×1275mm, and the rolling specification of No.10~12 is 3.0×1110mm.

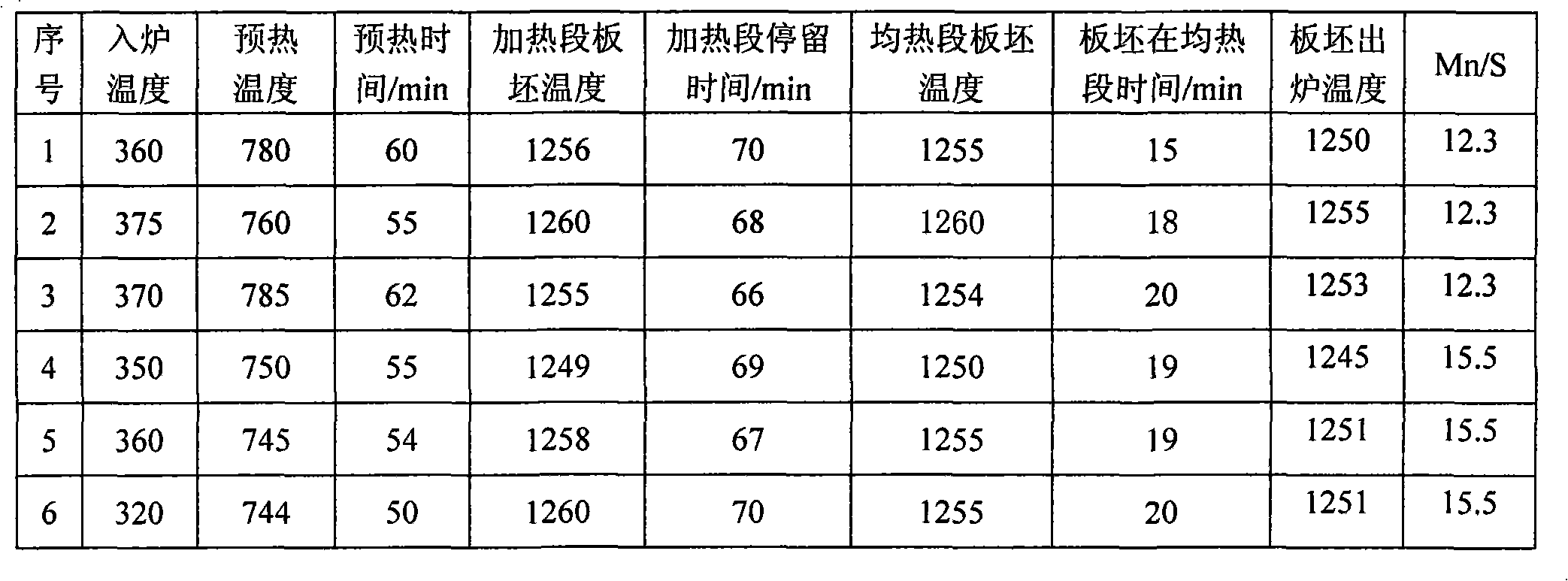

[0020] Table 1 Key points of process control, ℃

[0021]

[0022]

[0023] 1. For No. 1-9 slabs, stack cooling after off-line, the calculated cooling rate is 8°C / min, and air-cooling after No. 10-12 slabs off-line;

[0024] 2. The temperature and residence time of the slabs in each section of the heating furnace are shown in Table 1, and the slabs of No. The slab is cold loaded and heated according to conventional methods;

[0025] 3. For rough descaling of slabs No. 1 to 9, single descali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com