Continuous processing method of printed color coated steel plates at normal temperature

A processing method, color coating technology, applied to the surface coating liquid device, coating, surface pretreatment, etc., can solve the problems of increased production cost, inconvenient production, difficult control of process quality, etc., to achieve long-term aging resistance Performance and shelf life, cost savings, ease of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

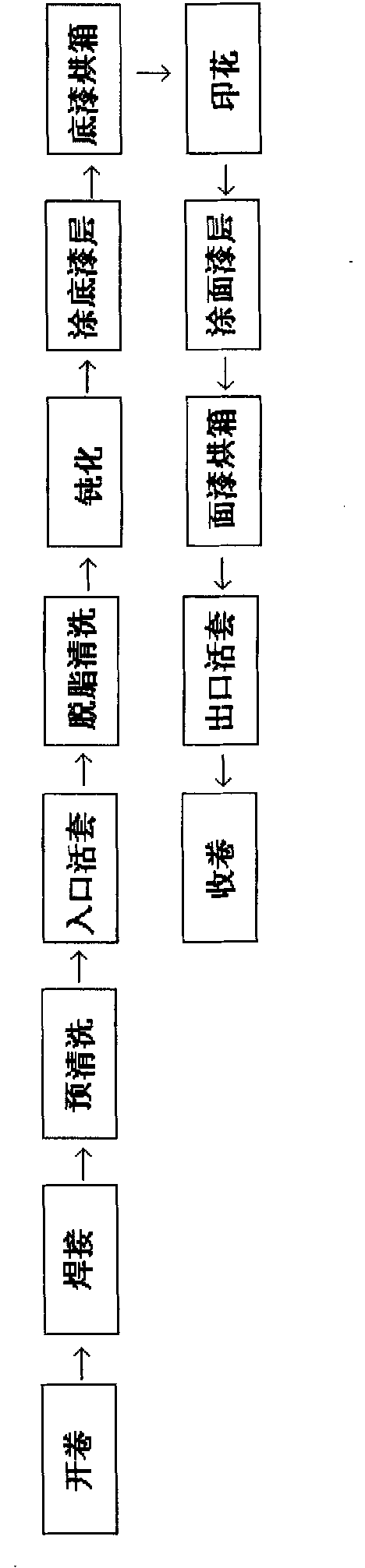

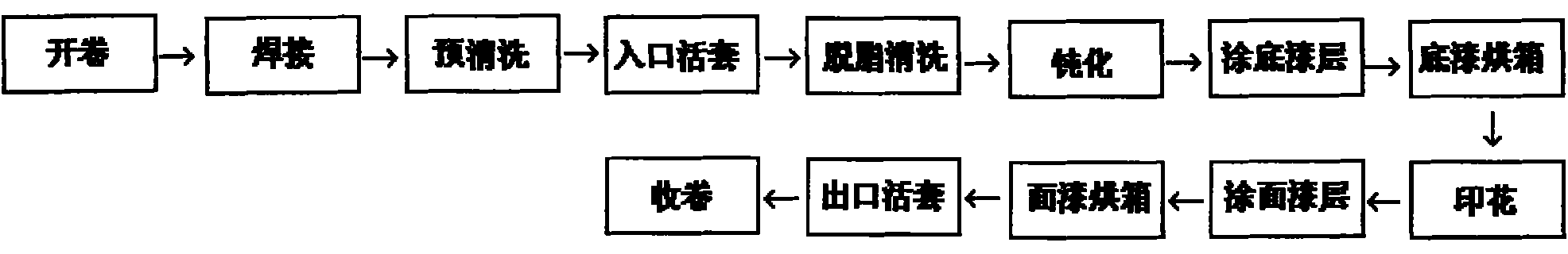

[0017] As shown in the accompanying drawings, a continuous processing method for printed color coated steel sheets at room temperature of the present invention comprises the following steps:

[0018] A) Uncoiling and docking, uncoiling the color coated steel plate substrate in the steel coil state with an uncoiler, so that the steel coils are unrolled into steel strips, and after uncoiling, the steel strips unrolled on each steel coil are welded head to tail by welding, That is to say, the steel strips unfolded on the adjacent steel coils are connected to each other, so as to meet the requirements of the subsequent continuous processing process and obtain the steel plate to be cleaned.

[0019] B) degreasing cleaning, introducing the steel plate to be cleaned obtained by step A) into a degreasing tank filled with degreasing agent solution for degreasing, in the degreasing tank, the consumption of degreasing agent is 5g / L, the temperature of degreasing agent solution is 70 ℃, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com