Epoxy resin composition, prepreg, metal clad laminate and multilayer printed wiring board

A technology of epoxy resin and composition, applied in the direction of metal layered products, synthetic resin layered products, printed circuits, etc., can solve the problems of reduced drilling processability and easy wear of drill bits, and achieve excellent interlayer adhesion, Good desmear treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

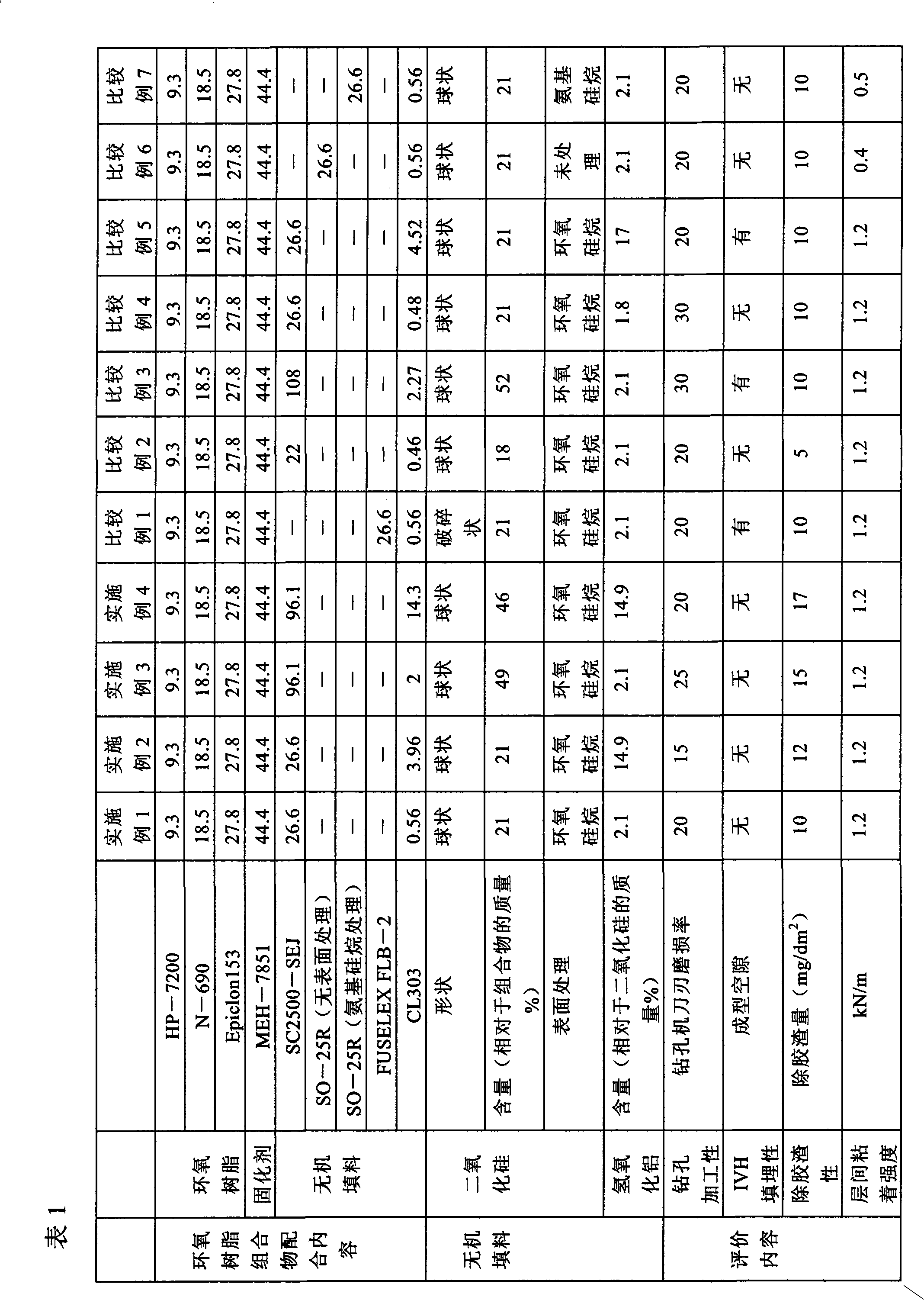

[0035] Hereinafter, the present invention will be specifically described by way of examples.

[0036] As the epoxy resin, "HP-7200" (epoxy equivalent 280) manufactured by Dainippon Ink Chemicals Co., Ltd., which is an epoxy resin having a dicyclopentadiene skeleton, and Dainichi, which is an epoxy resin having a novolak skeleton, were used. "N-690" manufactured by Nippon Ink Chemical Industry Co., Ltd. (epoxy equivalent is 225), halogenated epoxy resin (flame retardant) is "Epiclon153" manufactured by Dainippon Ink Chemical Industry Co., Ltd. (epoxy equivalent is 400, The bromine content is 48.0% by mass).

[0037] As a curing agent, "MEH-7851" manufactured by Meiwa Kasei Co., Ltd., which is a phenolic resin curing agent having a biphenyl skeleton, was used.

[0038] As the inorganic filler, "SC2500-SEJ" manufactured by admatechs.co., which is spherical silica surface-treated with epoxysilane, "CL303" manufactured by Sumitomo Chemical Co., Ltd., aluminum hydroxide, and crushe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com