Drilling machining device for metal plate

A processing device and metal plate technology, applied in metal processing equipment, boring/drilling, drilling/drilling equipment, etc., can solve problems such as low efficiency and poor effect, reduce errors, improve drilling accuracy, The effect of improving the drilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other; the present invention will be described in detail below with reference to the accompanying drawings and in combination with the embodiments.

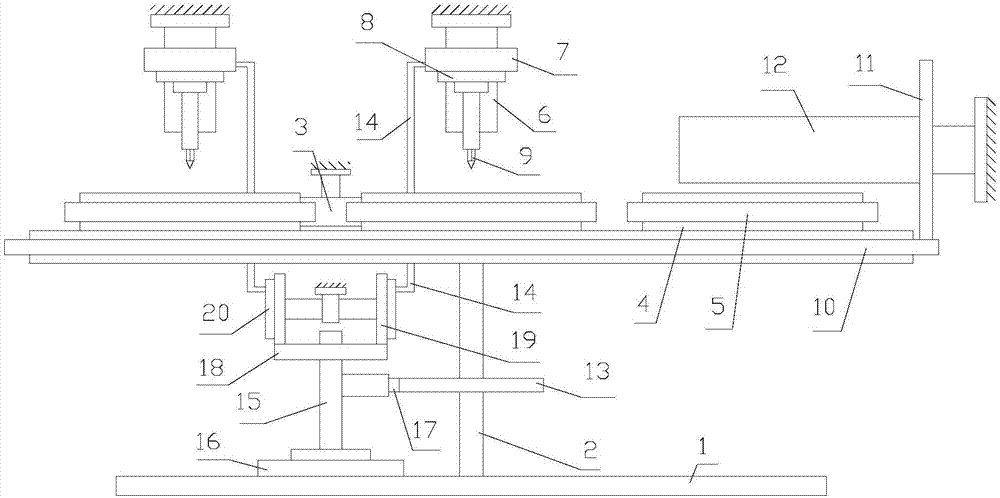

[0022] refer to figure 1 :

[0023] A metal plate drilling processing device proposed by the present invention includes a base 1, a support shaft 2, a driving mechanism, a processing table, a plurality of supporting units, N first racks 3, and (N+1) drilling mechanisms, Wherein, N is a positive integer.

[0024] The support shaft 2 is installed on the base 1 for vertical rotation; the driving mechanism is used to drive the support shaft 2 to rotate; the processing table is installed on the support shaft 2 .

[0025] A plurality of support units are sequentially distributed around the circumference of the support shaft 2 , the support units include a support plate 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com