Drawing plug of pipe material and drawing method employing the plug

A processing method and pipe technology, applied in the direction of the mandrel, etc., can solve the problems that the drawing performance of the plug for drawing processing cannot be properly improved, and the vibration pattern defect and the vibration pattern defect plug are not studied, so as to reduce product defects and vibration lines. Defect prevention and plug breakage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] As a test pipe blank, a steel pipe made of S45C (0.44C-0.75Mn-0.15Cr-0.1Ti steel material) specified in JIS G4051, which is a carbon steel pipe for machine structure, was prepared, and various plugs were used for drawing. Processing, evaluate the processing status at this time. Regarding the drawing process, five types of cold-worked tube wall thickness series (schedule) shown in Table 1, Sch.

[0054] The area reduction ratio Rd (%) shown in Table 1 was calculated from the following formula (4).

[0055] Rd={(D 0 -D 1 ) / D 0}×100(%)... (4)

[0056] Among them, D 0 : Sectional area before processing (mm 2 ), D 1 : Sectional area after processing (mm 2 )

[0057] Table 1

[0058]

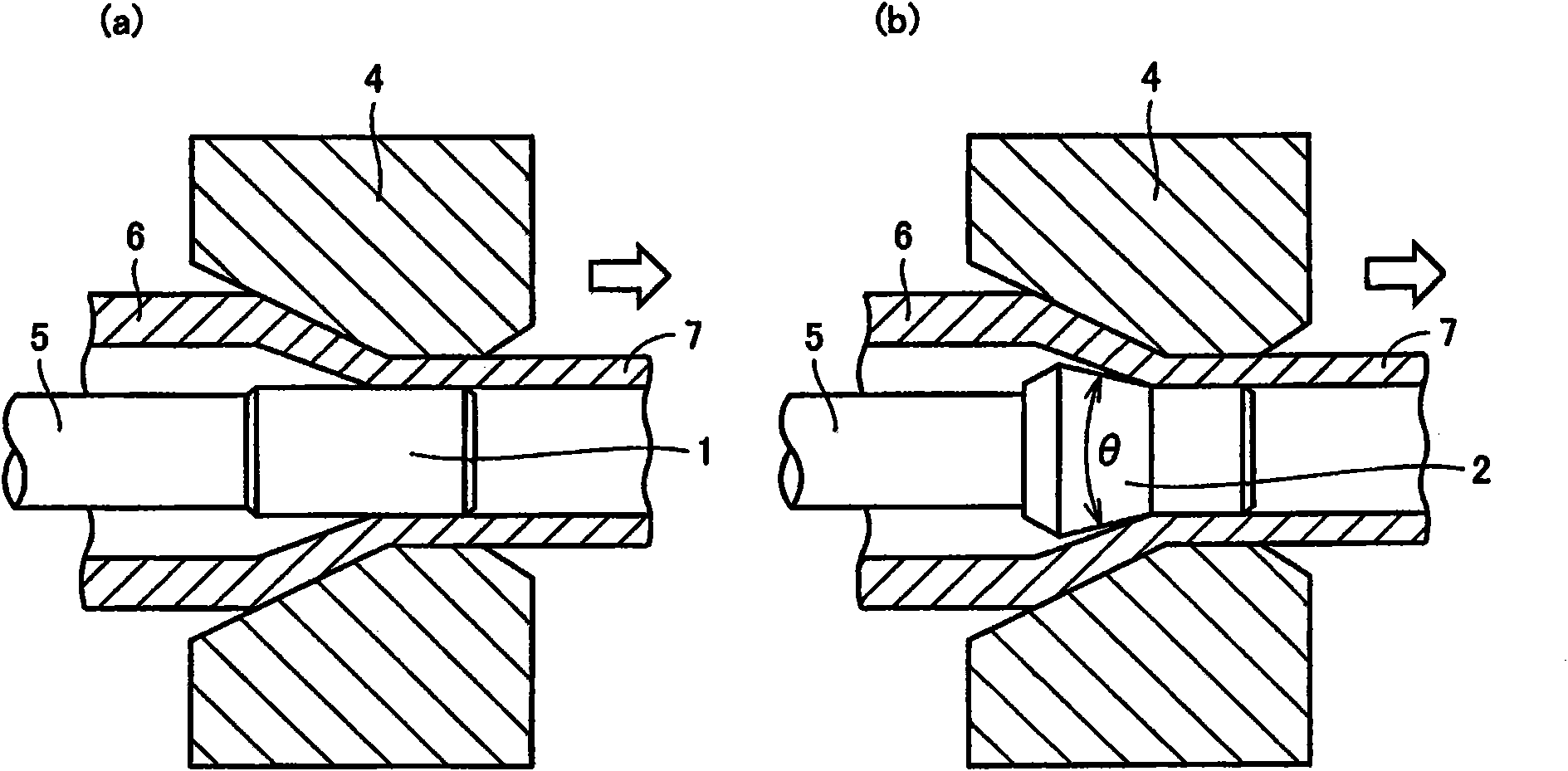

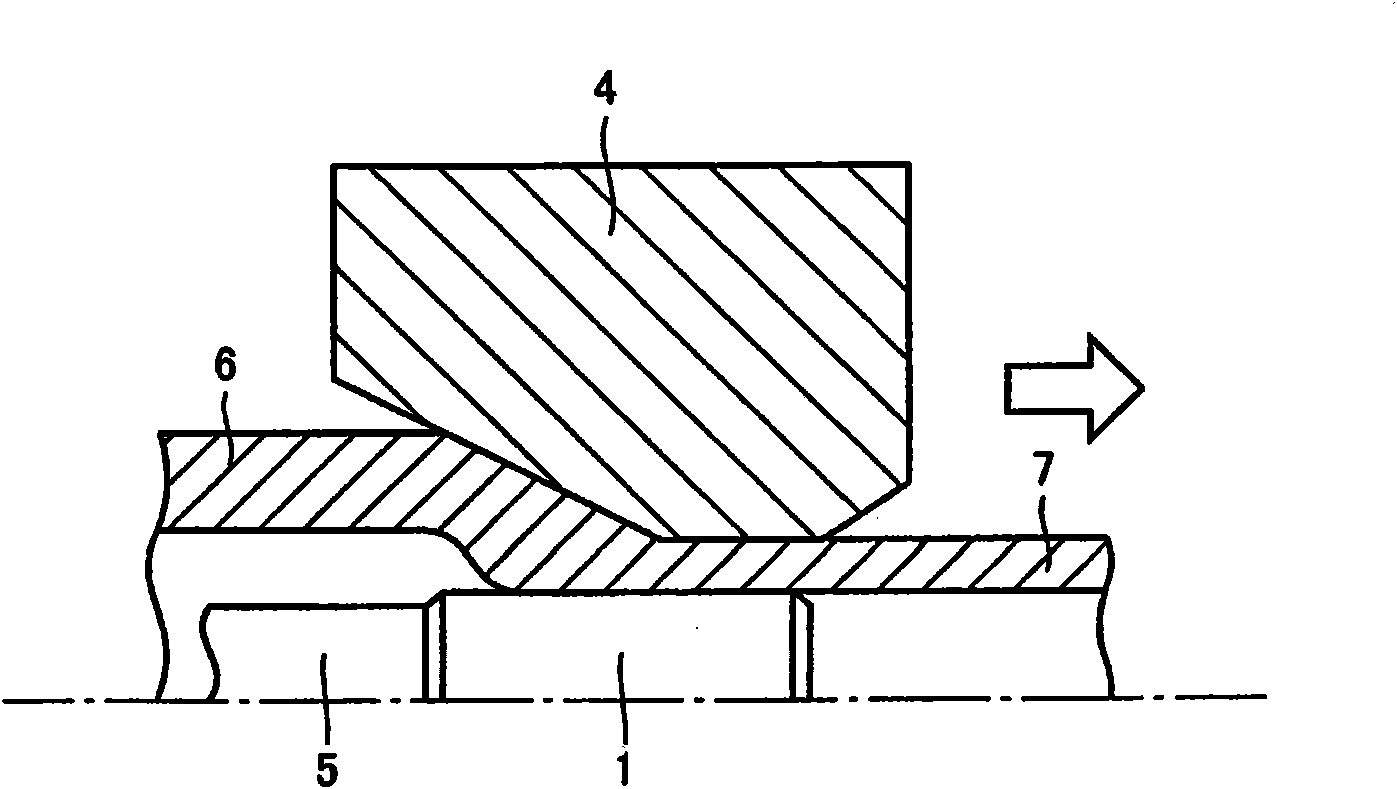

[0059] The plugs used in the drawing process are the above image 3 cylinder head shown, above Figure 4 SF head shown and above Figure 5 2-stage tapered head shown. For the drawing die used at the same time, the taper angle α of the introduction portion was set to 20 degree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com