Crack prediction method and device

A technology of fracture prediction and longitudinal line, which is applied in earthwork drilling, wellbore/well components, seismic signal processing, etc. It can solve the problems of high cost, low S-wave signal-to-noise ratio, troublesome converted wave processing, etc. The effect of improving the rate and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

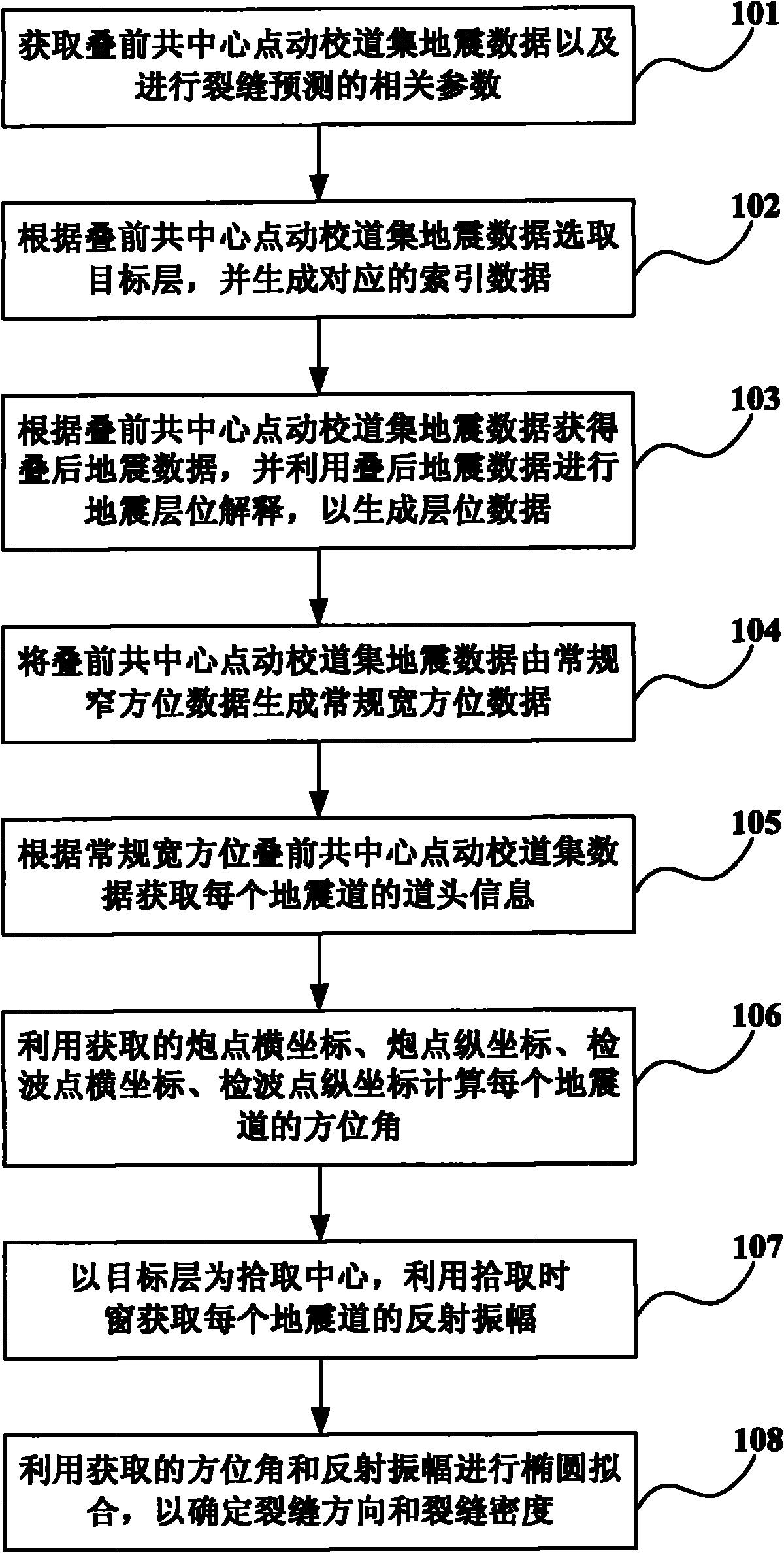

[0050] An embodiment of the present invention provides a fracture prediction method, such as figure 1 As shown, the method includes:

[0051]Step 101, acquiring pre-stack common-centre jogging gather seismic data and relevant parameters for fracture prediction, the relevant parameters include: longitudinal survey line bin size, transverse survey line bin size and picking time window;

[0052] Step 102: Obtain the target layer according to the seismic data of the pre-stack common-center jogging calibration gather, and generate corresponding index data; the index data includes longitudinal line number, cross line number, start track number, end track number, and coverage times , the maximum number of coverage;

[0053] Step 103, obtaining post-stack seismic data according to the pre-stack seismic data of the common center jogging calibration gather, and using the post-stack seismic data to perform seismic horizon interpretation to generate horizon data;

[0054] Step 104, usin...

Embodiment 2

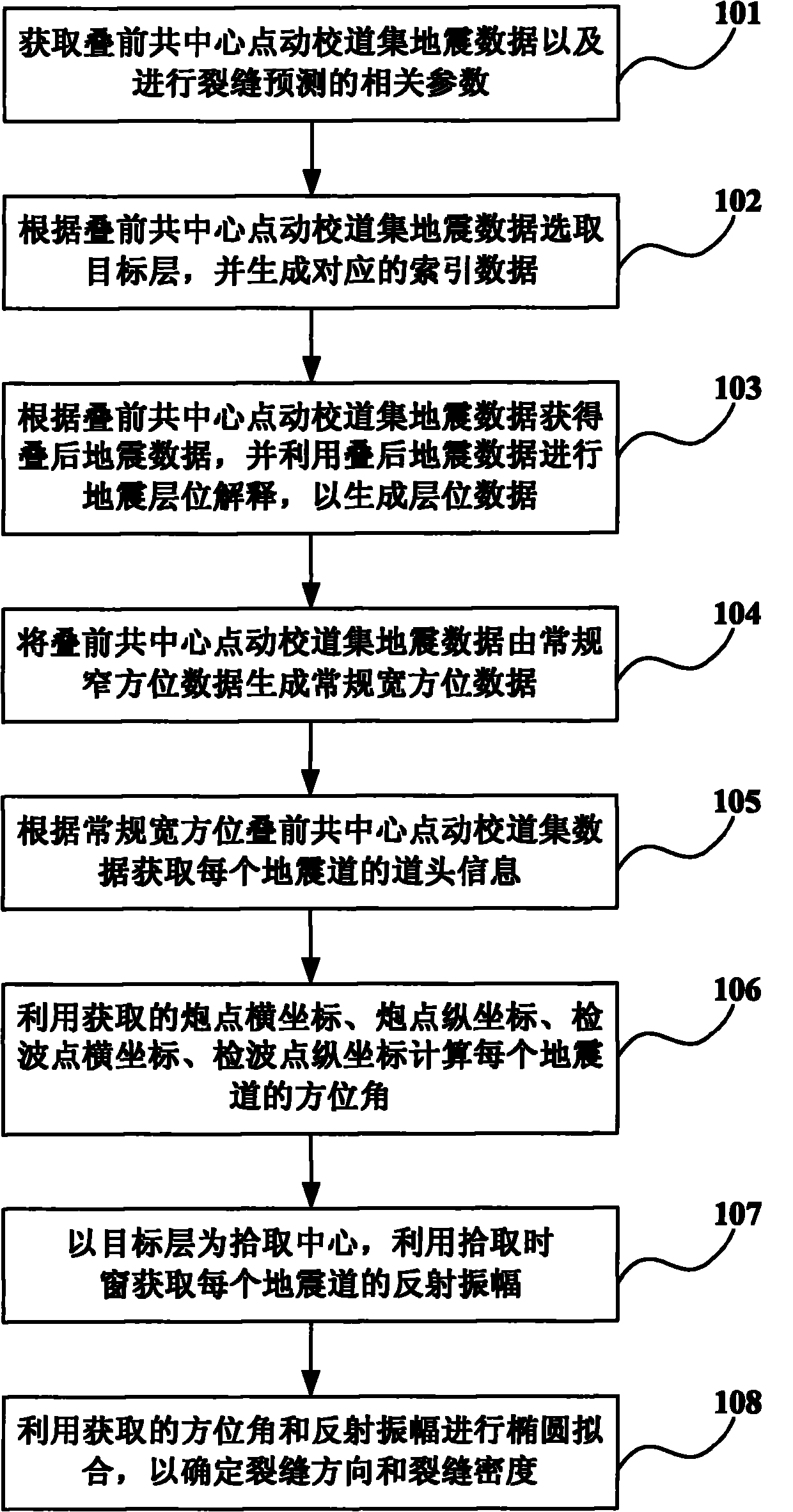

[0093] The embodiment of the present invention provides a crack prediction method, which is further described on the basis of Embodiment 1, as follows figure 2 As shown, the method includes:

[0094] Step 201, acquiring pre-stack common-center jogging calibration gather seismic data and related parameters for fracture prediction, the related parameters include: longitudinal survey line bin size, transverse survey line bin size and picking time window;

[0095] In this embodiment, the relevant parameters may also include: longitudinal survey line increment, transverse survey line increment, minimum offset, maximum offset, offset bin size, azimuth bin size and smoothing parameters ;

[0096] Among them, the longitudinal survey line increment and transverse survey line increment can be used to control the workload, control the number of inline lines and crossline lines; the minimum offset and maximum offset can be used to control the range of pre-stack data used; offset The di...

Embodiment 3

[0127] An embodiment of the present invention provides a crack prediction device, such as Figure 15 As shown, the device includes: a data acquisition unit 1501, a first generation unit 1502, a second generation unit 1503, a third generation unit 1504, an information acquisition unit 1505, an azimuth calculation unit 1506, an amplitude acquisition unit 1507 and a fitting unit 1508 ;in,

[0128] The data acquisition unit 1501 is used to acquire the seismic data of the pre-stack common-center jogging calibration gather of the target layer and related parameters for fracture prediction, and the related parameters include: longitudinal survey line bin size, transverse survey line bin size and picking time window ;

[0129] The first generation unit 1502 is used to acquire the target layer according to the seismic data of the pre-stack common-center jogging trace set, and generate corresponding index data and layer data; the index data includes longitudinal line number, transverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com