Capacitance type continuous material level sensor

A capacitive, sensor technology, applied in the direction of the liquid level indicator for the measurement of physical variables, can solve the problems such as the inability to ensure the relative fixation of the protective cover, the reduction of the service life of the sensor, and the large measurement error, and achieve stable and reliable calibration signals. Realistic, simple effects of signals and scaled signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

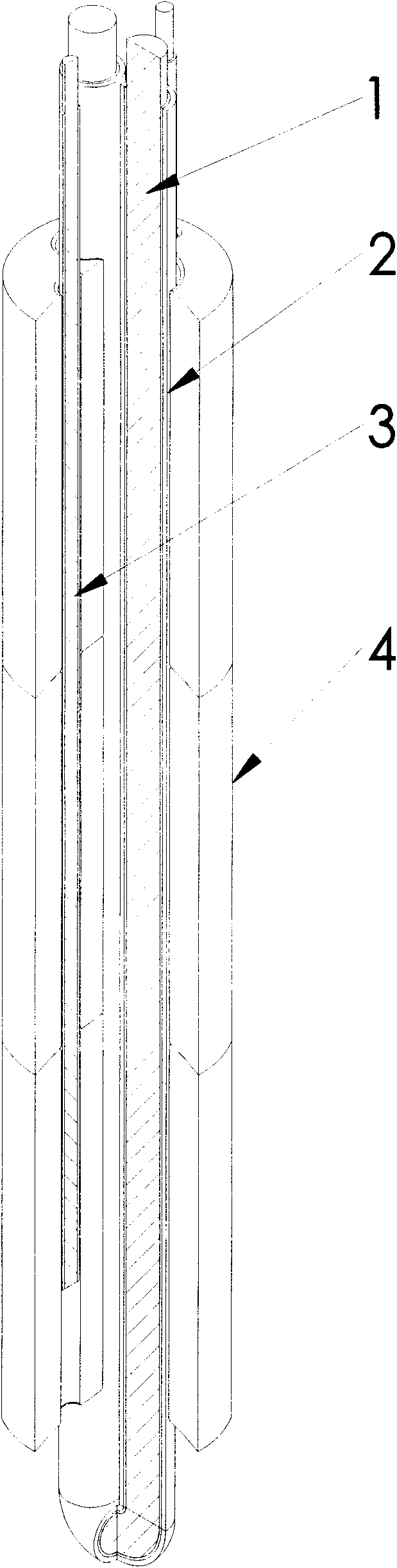

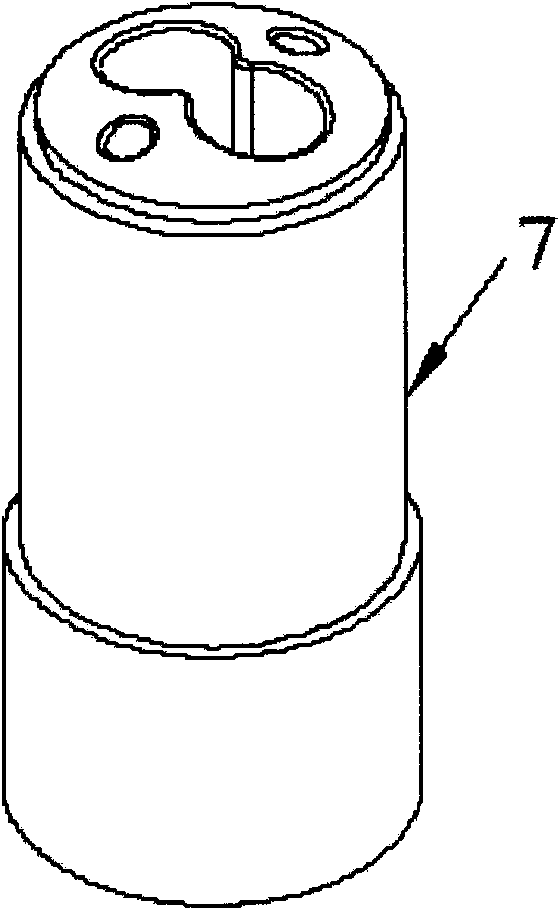

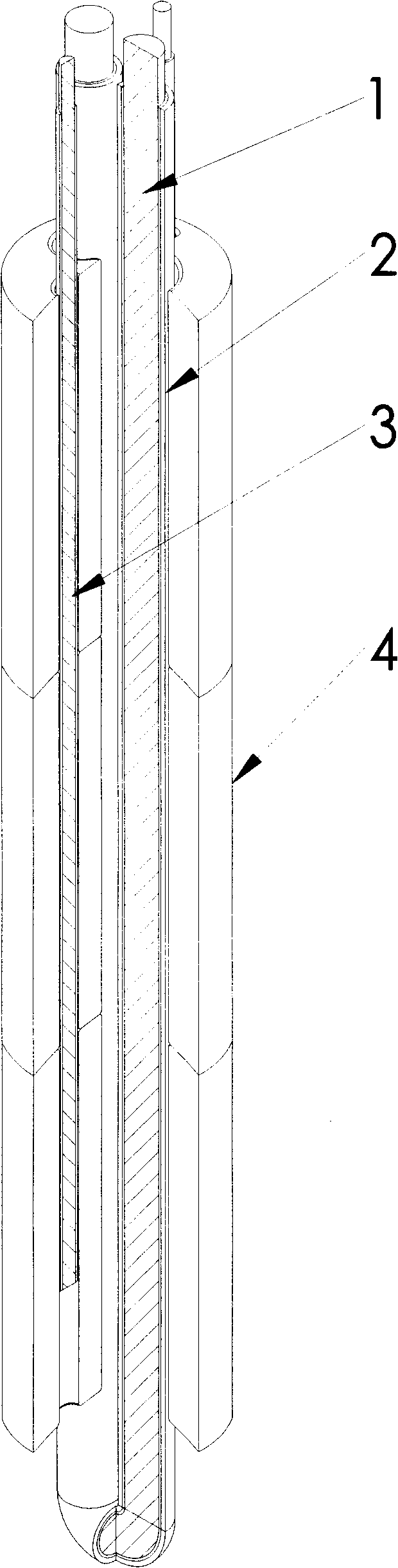

[0019] from figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 It can be seen from the figure that the present invention is provided with a metal main pole 1, the upper end of the main pole 1 is provided with a fixed flange, and the upper part of the flange is provided with a capacitive transmitter 5 for processing electrical signals, and the main pole passes through an insulating pad Insulated and fixed with the flange plate and the silo, the main pole and the silo wall are respectively one pole, forming a variable medium continuous capacitor, and its upper end is electrically connected with the capacitance transmitter 5, and the metal main pole 1 is a flexible conductive steel cable A double-strand structure folded in half from the bottom, the outer side of each flexible conductive steel cable of the metal main pole 1 is covered with a flex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com