Underlying transverse biomass burning gasification boiler

A gasification boiler and biomass technology, which is applied in the field of gasification boilers, can solve the problems of dead ends, insufficient combustion, and smoldering of fuel, so as to reduce dust emissions, have strong aerodynamic properties, and have no dead ends in combustion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

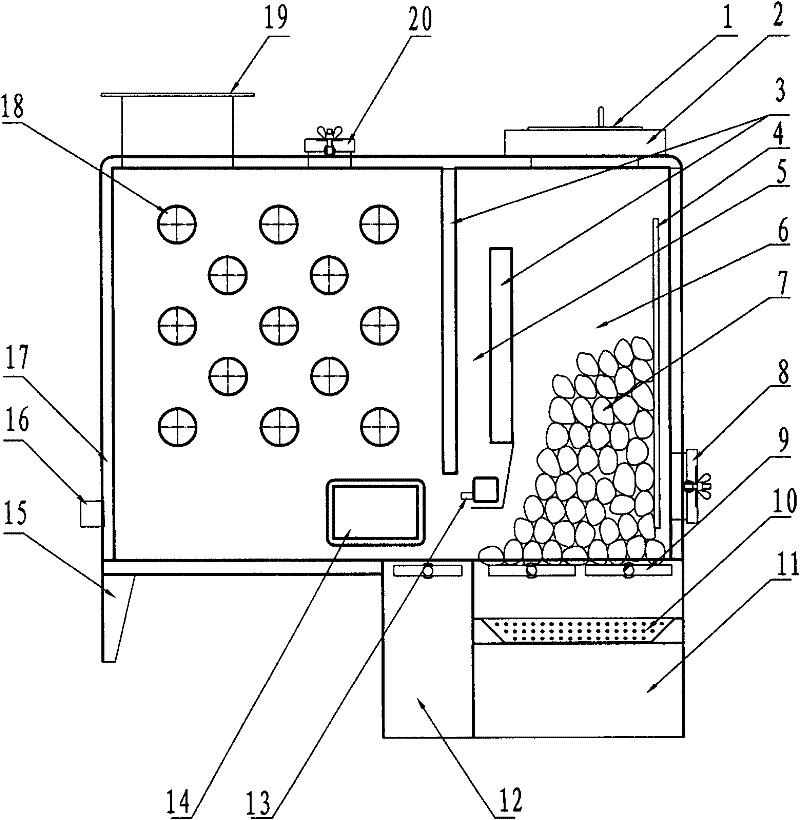

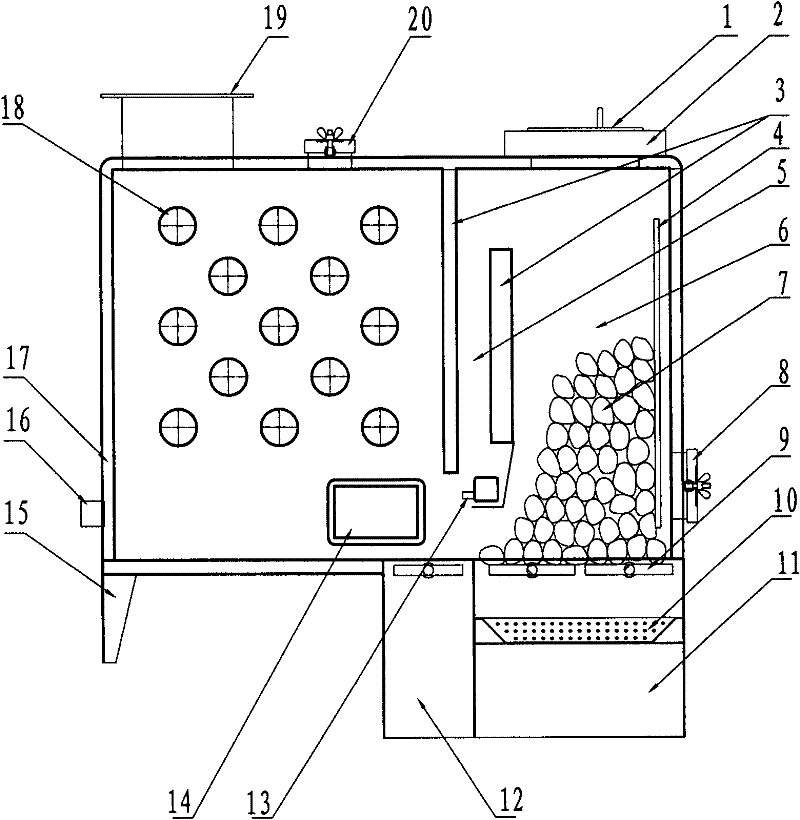

[0013] The present invention will be described in detail below with reference to the accompanying drawings.

[0014] The boiler of the present invention is dedicated to the use of renewable energy "biomass fuel". The boiler is composed of three parts: one is the biomass gasification chamber; the other is the gasification combustion chamber; the third is the ash chamber.

[0015] Biomass gasification chamber: There is a feeding cover 1 on the top, and a water seal tank 2, a positive pressure combustion gasification flue 5 and a secondary air duct 13 are installed in the furnace, and a movable furnace grate 9 is installed at the bottom. A secondary air duct tuyere is provided at the outlet of the positive pressure combustion gasification flue 5 . During work, after the fuel 7 is placed on the grate 9 and ignited, the fire burns horizontally. After the feeding is completed, the upper cover 1 is covered, and the bottom of the furnace is given a primary air to the furnace through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com