Improved LED lamp bar

A technology of LED strips and LED bulbs, applied in lighting and heating equipment, semiconductor devices of light-emitting elements, point-like light sources, etc., can solve problems such as short circuits, limited lighting angles, and reduced decorative effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

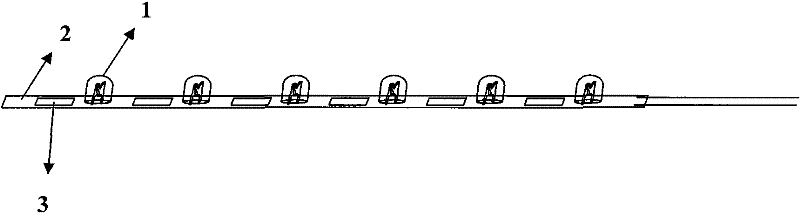

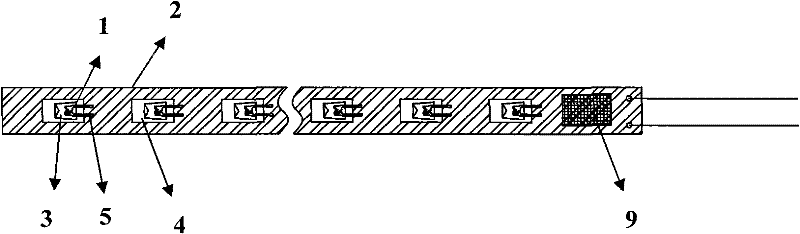

[0014] refer to figure 1 Steady LED light bar, figure 2 LED light strips with control circuits, such as meteor lamps, are used to carry LED light bulbs (1) on the long strip circuit board (2) of the display part, and are regularly spaced next to each LED light bulb (1). Drill holes (3), weld the LED lamp pins (4) to the circuit board (2), and place the LED lamp head (5) in the holes (3). The LED light bulb (1) can emit light on both sides of the circuit board (2) after being powered on, so that the effect of omnidirectional light can be achieved without adding another LED light bulb.

[0015] refer to figure 2 , on the long circuit board (2) used to carry the LED light bulb (1) on the display part of the LED light bar, regularly and periodically punch holes (3) next to each LED light bulb (1), and place the LED light bulb (1) Weld vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com