Engine diesel oil emulsifying agent and engine emulsified diesel oil

An engine and emulsifier technology, which is applied in the field of engine diesel emulsifiers, can solve the problems of stability, viscosity and emulsification cost, difficulty in adapting to industrial production, high viscosity of emulsified diesel oil, etc., and achieve low emulsification dosage and emulsification cost Low, flammable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

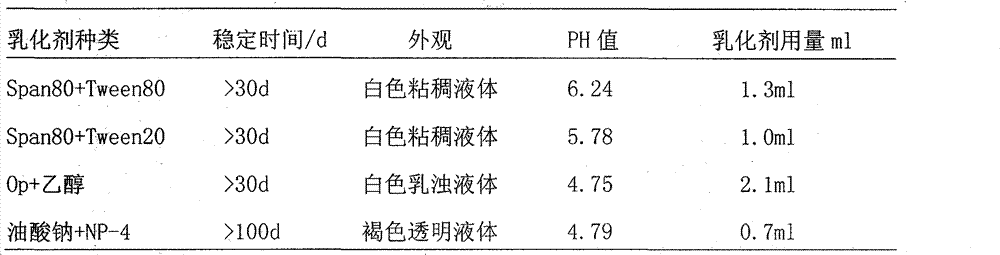

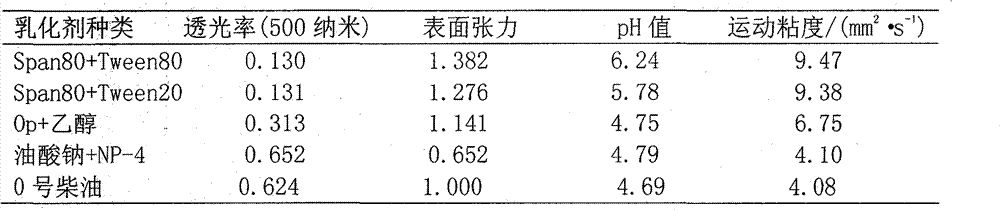

Method used

Image

Examples

Embodiment 1

[0019] Sodium oleate saturated solution, OP-ethanol, nonylphenol polyoxyethylene (4) ether NP-4 and magnesium chloride saturated solution are compounded with engine diesel emulsifier and 0# diesel oil at a volume ratio of 2:5:8:6 The volume ratio of 1:500 is mixed with water-containing diesel oil, and water is added dropwise at a temperature of 40-55 ° C. The total amount of dripping water accounts for 9-10% of the volume of diesel oil. The ultrasonic emulsification is fully emulsified for no less than 10 minutes, or stirred for 6 hours. Prepare 1# emulsified diesel oil.

Embodiment 2

[0021] Sodium oleate saturated solution, OP-ethanol, nonylphenol polyoxyethylene (4) ether NP-4 are mixed in a volume ratio of 2:5:10 to prepare a motor diesel emulsifier and 0# diesel oil in a volume of 1:500 Mix it with water-containing diesel oil, add water dropwise at 40-55°C, the total amount of dripping water accounts for 9-10% of the volume of diesel oil, emulsify fully with ultrasonic waves for not less than 10 minutes, or stir for 6 hours to obtain emulsified diesel oil. Add the engine diesel emulsifier of magnesium chloride saturated solution on the basis of the above-mentioned engine diesel emulsifier, that is, by volume of sodium oleate saturated solution, OP-ethanol, nonylphenol polyoxyethylene (4) ether NP-4 and magnesium chloride saturated solution The engine diesel emulsifier compounded at a ratio of 2:5:10:6 and 0# diesel oil are mixed with water-containing diesel oil at a volume ratio of 1:500, and water is added dropwise at a temperature of 40-55°C. 9-10% of...

Embodiment 3

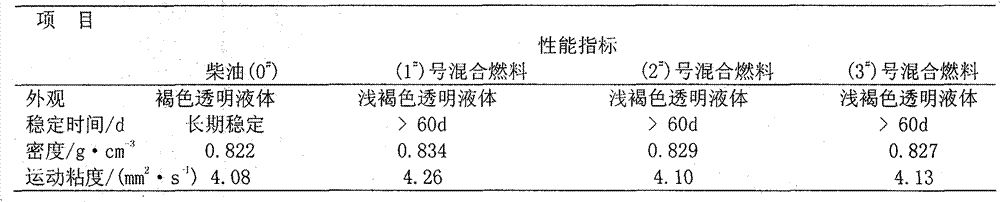

[0023] Sodium oleate saturated solution, OP-ethanol, nonylphenol polyoxyethylene (4) ether NP-4 and magnesium chloride saturated solution in a volume ratio of 2:5:12:6 compound engine diesel emulsifier and 0# diesel press, Mix with water-containing diesel oil at a volume ratio of 1:500, add water dropwise at a temperature of 40-55°C, the total amount of dripping water accounts for 9-10% of the volume of diesel oil, fully emulsify with ultrasonic waves for not less than 10 minutes, or stir for 6 3# emulsified diesel oil was produced in 1 hour.

[0024] The performance comparison of the No. 3 combustion is shown in Table 3

[0025]

[0026] Among them, the technical index of 2# emulsified diesel oil is the closest to that of diesel oil, and the emulsified effect is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com