Organic fertilizer and natural shade composting method thereof

A composting method and technology of organic fertilizer, applied in the directions of organic fertilizer, preparation of organic fertilizer, treatment of biological organic parts, etc., can solve the problem of reducing the content of organic matter, and achieve the effect of long fertilizer efficiency, restoration of original flavor, and low drop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: A preferred embodiment of the preparation method of plant extract

[0036] (1) Plant liquid extraction: Cut purslane, Eclipta oleracea, ghost needle grass, alfalfa and spinach (fresh) into fine sections, crush grapes, and take flower heads from chrysanthemums. Take 1 piece of these raw materials respectively. kg (if it is a dry product, take 1 / 4 kg), heat and decoct with 8-15 kg of mineral-treated activated water to concentrate into 5 kg of liquid, and the decoction time is 4-7 hours;

[0037] (2) Fermentation reaction treatment of concentrated plant extracts: 5 kg of concentrated extracts of purslane, eclipta, ghost needle grass, alfalfa, chrysanthemum, grape and spinach described in step (1) are respectively packed into ceramic tanks Add 20-100 grams of sugarcane juice and 10-20 grams of glutinous rice vinegar as auxiliary raw materials, and then seal the tank for 60-90 days; wherein, sugarcane juice refers to the liquid squeezed out of fresh sugarcane. ...

Embodiment 2

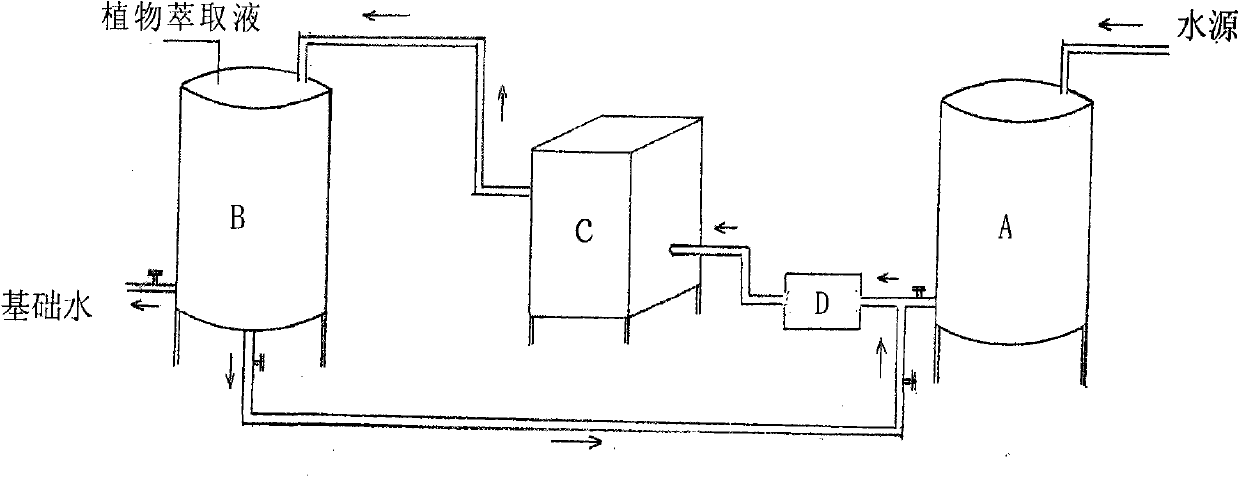

[0043] Example 2: Water treatment equipment for active small molecule water

[0044] The combination diagram of water treatment equipment for active small molecule water is shown in Figure 1. Picture 1-1 is the flow diagram of the liquid in the device, Figure 1-2is an assembly drawing of the device. It can be seen from Figure 1 that this equipment is composed of four sections of stainless steel tubes A1, A2, magnetic energy tubes, and BCD tubes. Each section of stainless steel tube is filled with different ores (such as Nuwa stone, crystal stone, magnetite, Baichuan stone (active vegetarian rice stone), thousand stones, precious stones, jasper stone, colorful crystal stone, etc.) and special biochemical ceramics, according to composed of different arrays. Specifically:

[0045] The A1 tube arranges Nuwa stone, crystal stone and magnet in sequence, and the parts by weight of each component are:

[0046] Nuwa stone 250-1000

[0047] Crystal Stone 300-1200

[0048] Magnet...

Embodiment 3

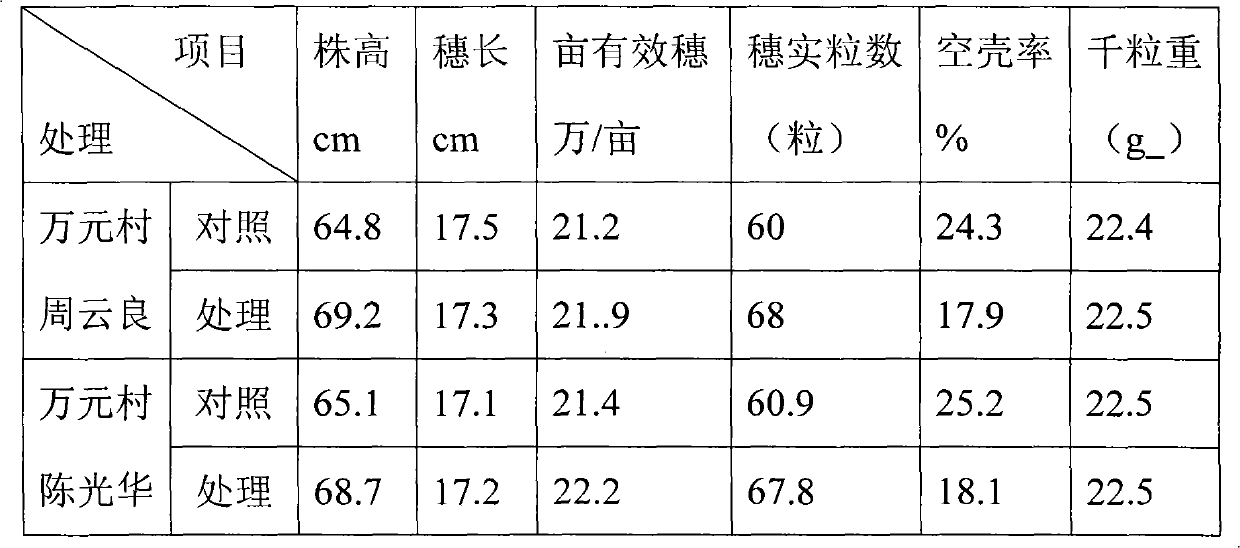

[0061] Embodiment 3: the curing solution deployment of organic fertilizer

[0062] figure 2 It is a diagram of the curing solution deployment system for organic fertilizers, where A represents the raw water tank, B represents the basic water tank, C represents the water treatment equipment, and D represents the pipeline pump; through this deployment system, the raw water tank A enters the water treatment equipment through the pipeline pump D C produces active small molecule water, and then enters the basic water tank B. Add the plant extract to the basic water bucket B, and then circulate through the pipeline pump D for 2-4 hours, in order to further fuse the plant extract with the active small molecule water to produce the basic water required for the maintenance solution.

[0063] The excrement used to deal with environmentally friendly dry and odorless pigs is mainly produced as manure (fertilizer), and its curing solution, that is, the preparation method of the fertilize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com