Novel chromium slag innocent treatment method

A technology of harmless treatment and chromium slag, which is applied in the field of harmless treatment of new chromium slag, can solve the problems of high treatment cost and large investment, and achieve the effect of harmless disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

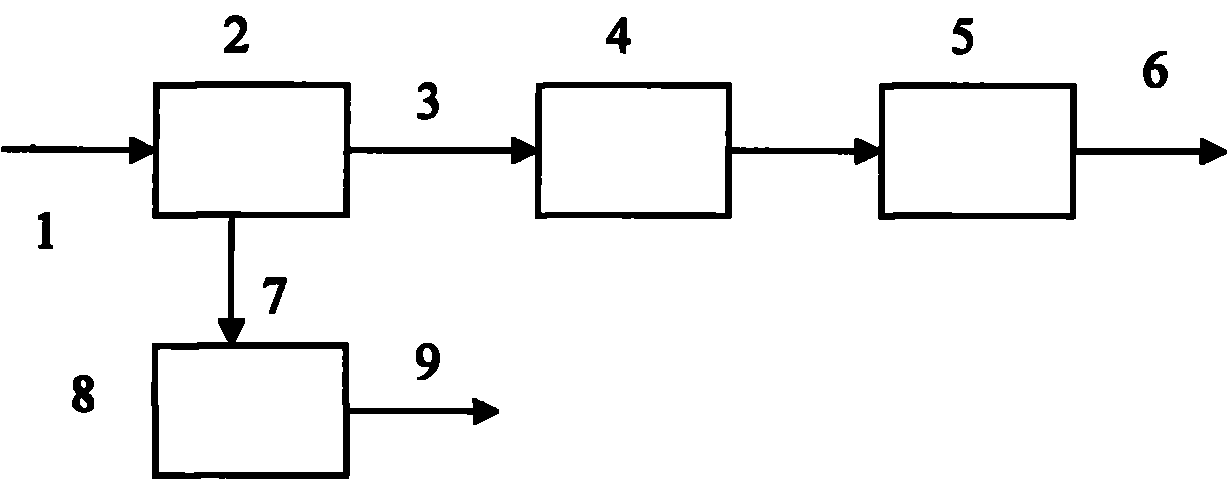

[0027] Such as figure 1 As shown, the chromium slag, quartz sand and alkaline agent soda ash are uniformly mixed according to the weight ratio of 25-45:35-75:5-22 to obtain a mixture 1, and the mixture 1 is added to the glass electric melting furnace 2, and the temperature is 1350-1500 It is fully melted at ℃, and the liquid level of glass in the electric melting furnace is stable after 8 to 10 hours. A small amount of dust-laden flue gas 3 is produced during the melting process, which is dedusted by the bag filter 4, and the purified flue gas is discharged into the atmosphere through the induced draft fan 5 and the chimney 6.

[0028] The mixture 1 is added to the electric glass melting furnace 2 to form a high-temperature glass liquid 7, which is discharged into the water quenching system 8 from the middle of the electric glass melting furnace 2, and the glass slag 9 is obtained after quenching with cold water.

Embodiment 2

[0030] Such as figure 1 As shown, the chromium slag, quartz sand and lime are uniformly mixed according to the weight ratio of 25:60:15 to obtain the mixture 1, which is added to the glass electric melting furnace 2 and fully melted at 1350°C. After 10 hours, the molten glass in the electric melting furnace The surface is stable. A small amount of dust-laden flue gas 3 is produced during the melting process, which is dedusted by the bag filter 4, and the purified flue gas is discharged into the atmosphere through the induced draft fan 5 and the chimney 6.

[0031] The mixture 1 is added to the electric glass melting furnace 2 to form a high-temperature glass liquid 7, which is discharged into the water quenching system 8 from the middle of the electric glass melting furnace 2, and the glass slag 9 is obtained after quenching with cold water.

Embodiment 3

[0033] Such as figure 1 As shown, the chromium slag, quartz sand and alkaline agent soda ash are evenly mixed according to the weight ratio of 45:45:10 to obtain a mixture 1, which is added to the glass electric melting furnace 2 and fully melted at 1500 ° C. After 8 hours, the electric melting furnace The inner glass liquid level is stable. A small amount of dust-laden flue gas 3 is produced during the melting process, which is dedusted by the bag filter 4, and the purified flue gas is discharged into the atmosphere through the induced draft fan 5 and the chimney 6.

[0034] The mixture 1 is added to the electric glass melting furnace 2 to form a high-temperature glass liquid 7, which is discharged into the water quenching system 8 from the middle of the electric glass melting furnace 2, and the glass slag 9 is obtained after quenching with cold water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com