Color adjusting system for adjusting color of cast polyurethane elastomer product

A technology of polyurethane elasticity and color matching system is applied in the field of polyurethane elastomer product casting, which can solve the problems of low efficiency, troublesome operation and inability to change, and achieve the effect of simple manufacturing, easy operation and no waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

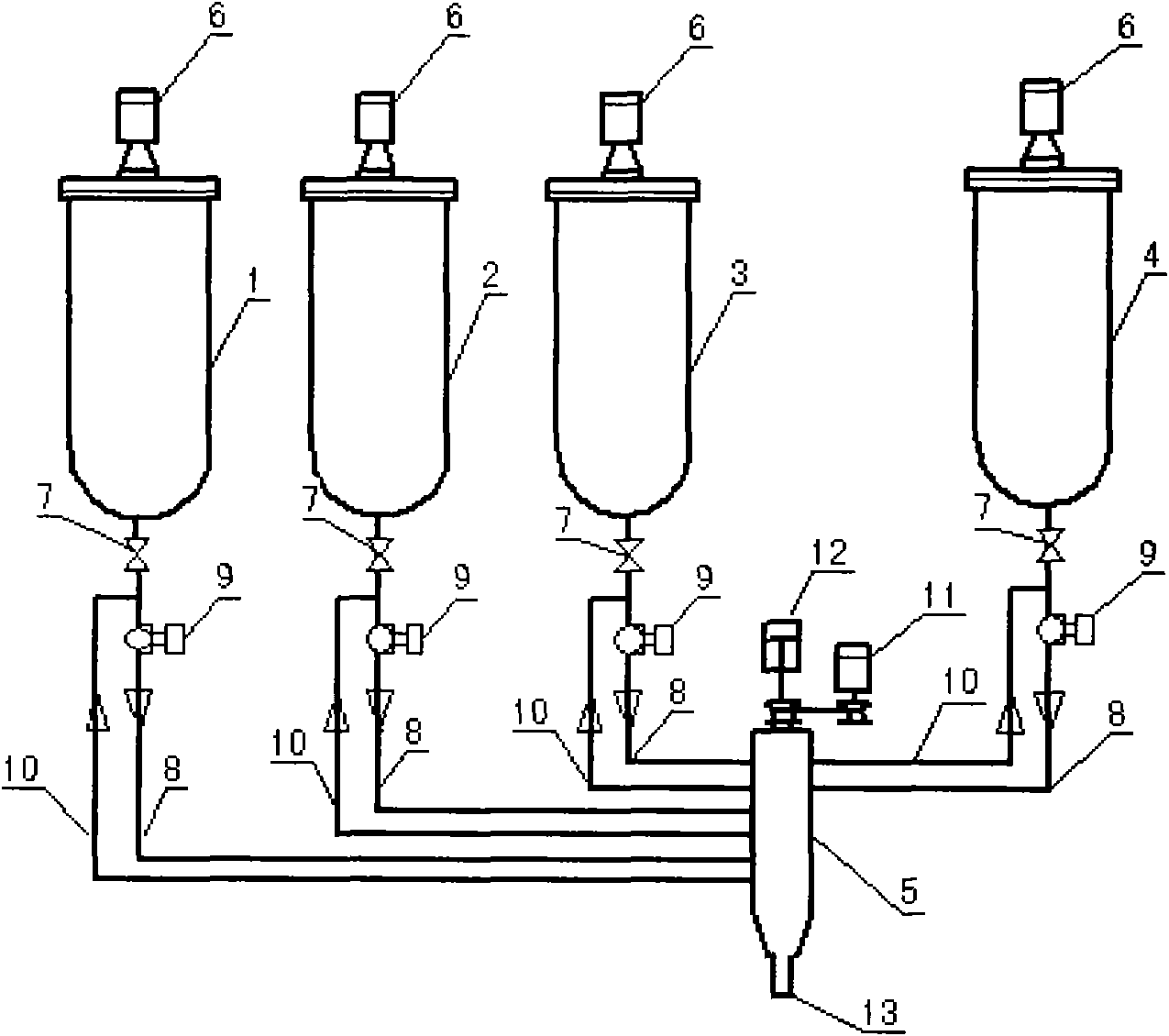

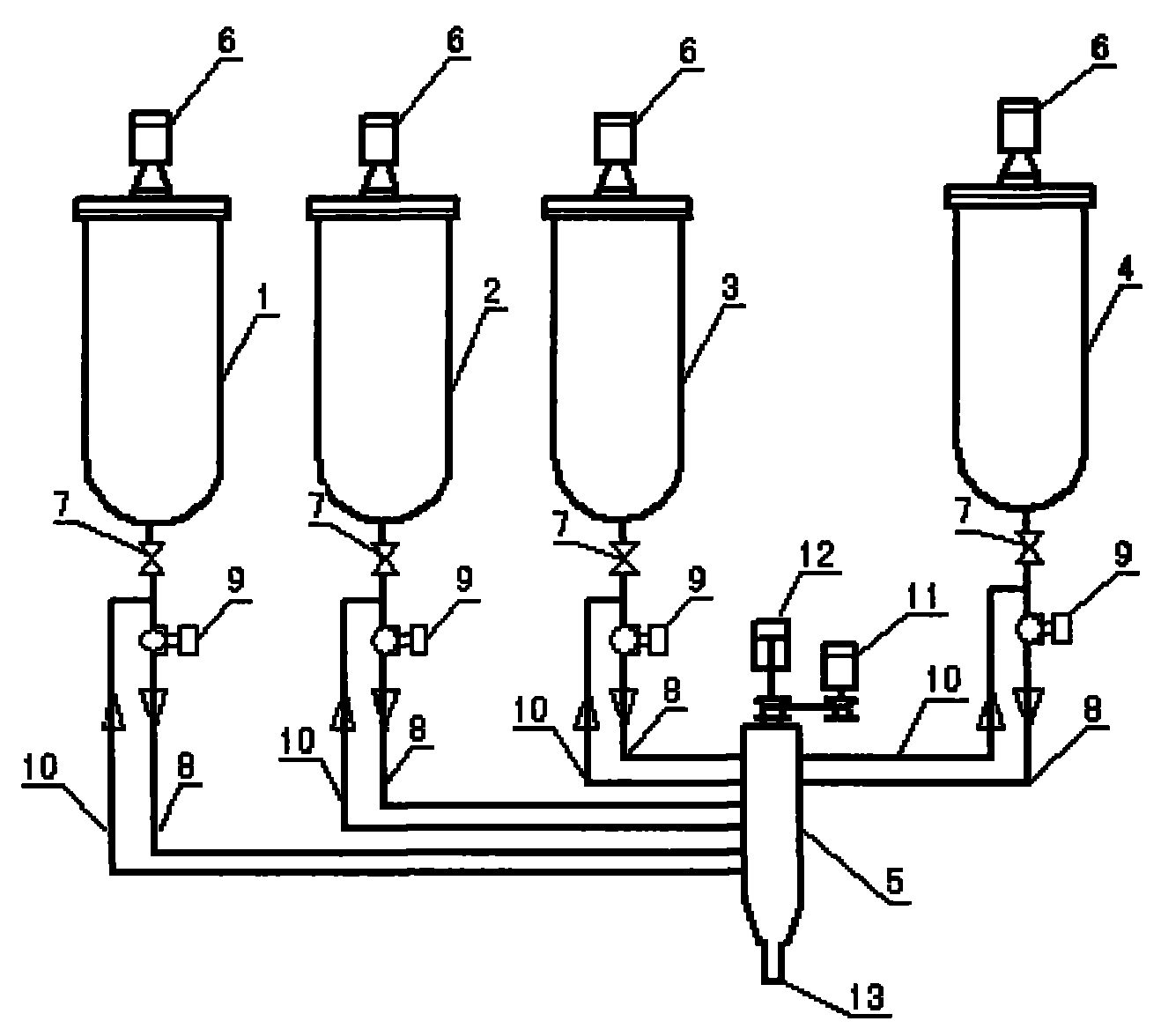

[0011] A kind of toning system that adjusts the color of casting polyurethane elastomer product comprises paint tank I 1, paint tank II 2, paint tank III 3, prepolymer tank 4 and mixing chamber 5 (referring to figure 1 ).

[0012] Paint tank I 1, paint tank II 2, paint tank III 3, and the top of the prepolymer tank 4 are respectively equipped with a mixer 6, and their lower ends are respectively provided with an output pipeline 8 with a control valve 7, and the output pipeline 8 is respectively mixed with The chamber 5 is connected; a metering pump 9 is provided under the control valve 7 and on the output pipe 8; a return pipe 10 is provided on the output pipe 8 between the control valve 7 and the metering pump 9, and the return pipe 10 is connected to the mixing chamber 5 respectively. connected; the top of the mixing chamber 5 is provided with a pouring / reflux solenoid valve 12 connected to the mixer 11, and a pouring head 13 in an inverted triangle shape is provided below i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com