A corn multi-stage crushing equipment for pig feed preparation

A technology of crushing equipment and pig feed, applied in grain processing and other directions, can solve the problems of waste of raw materials and uneven crushing, and achieve the effect of not wasting raw materials, speeding up grinding speed, and facilitating work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

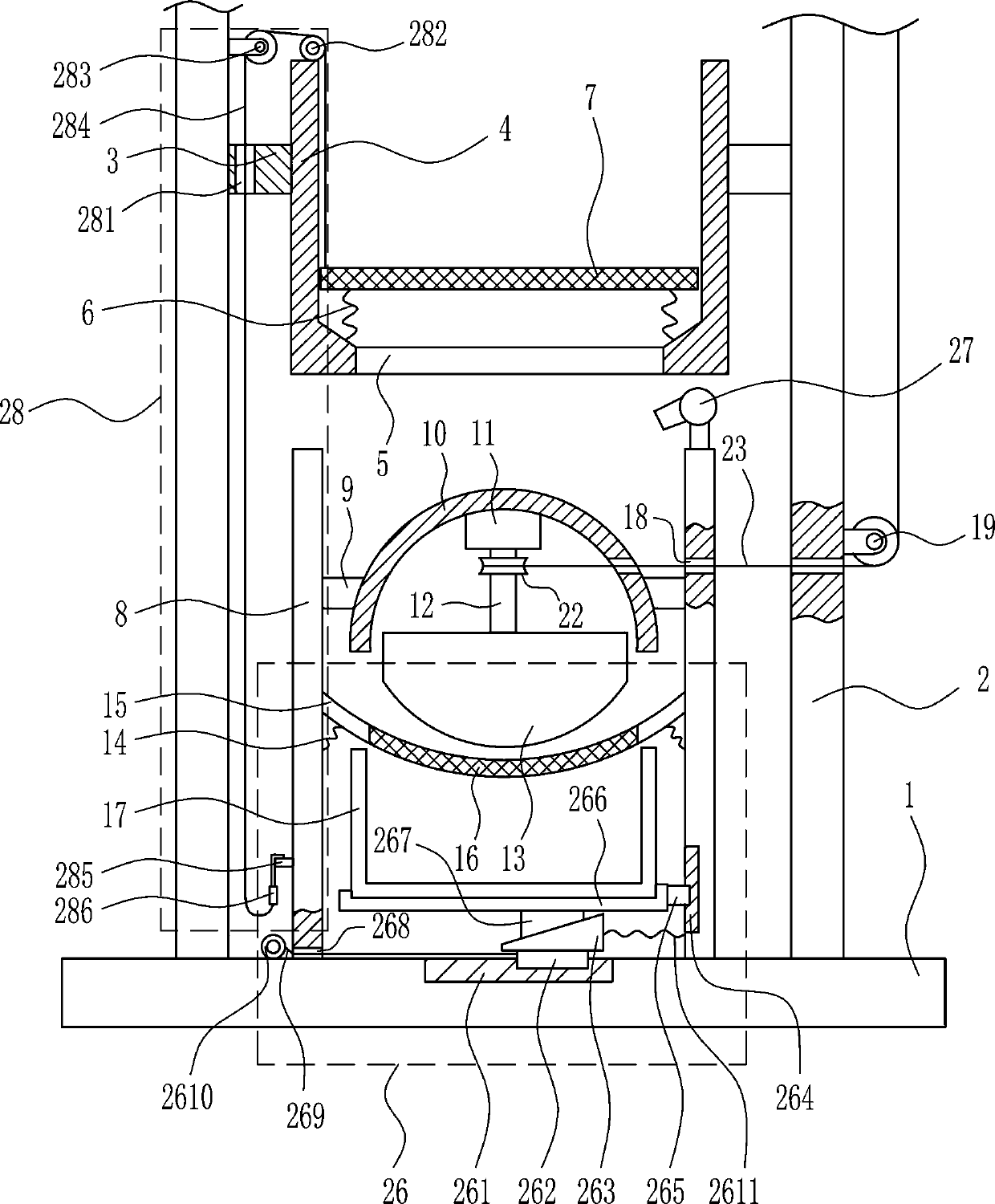

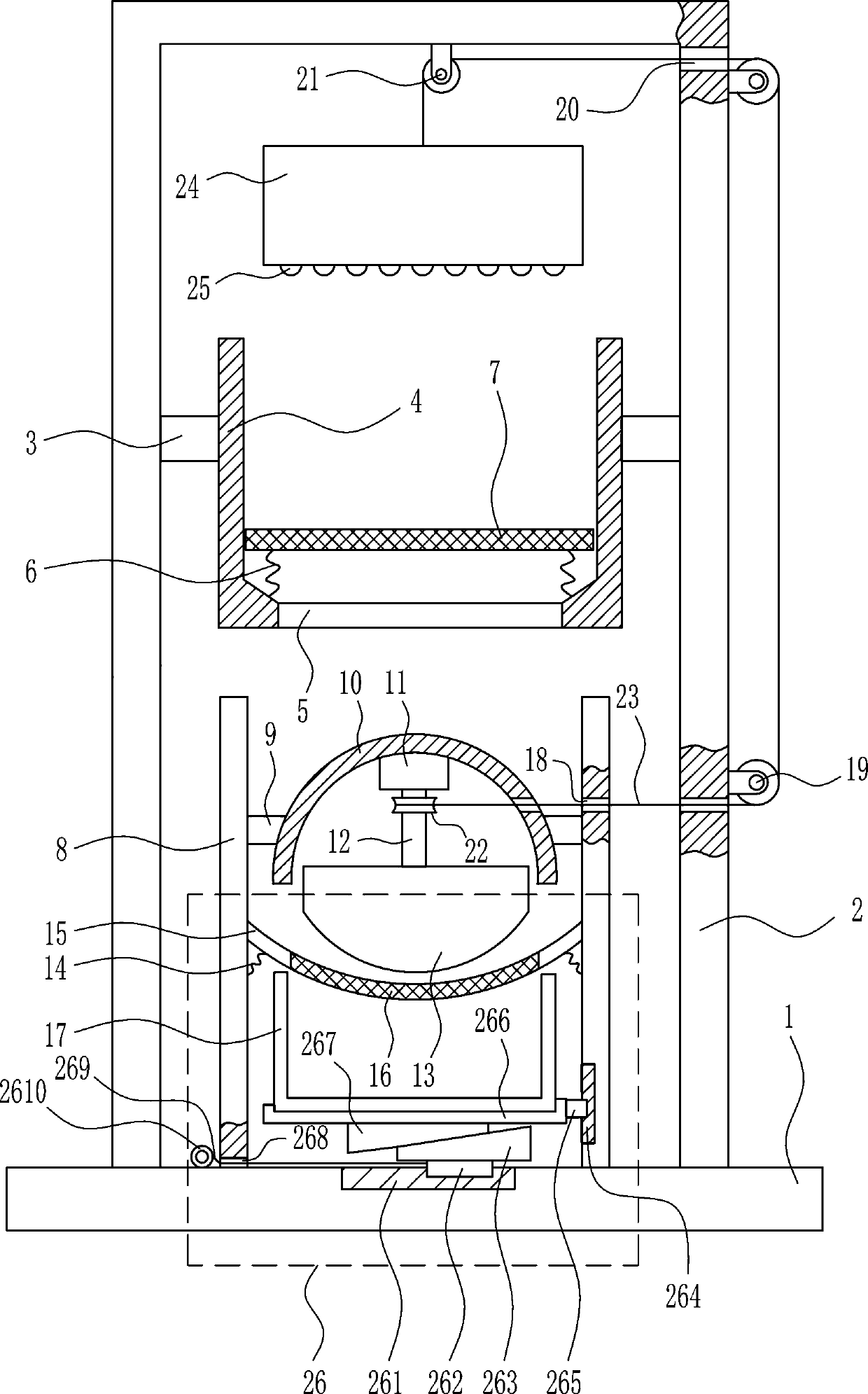

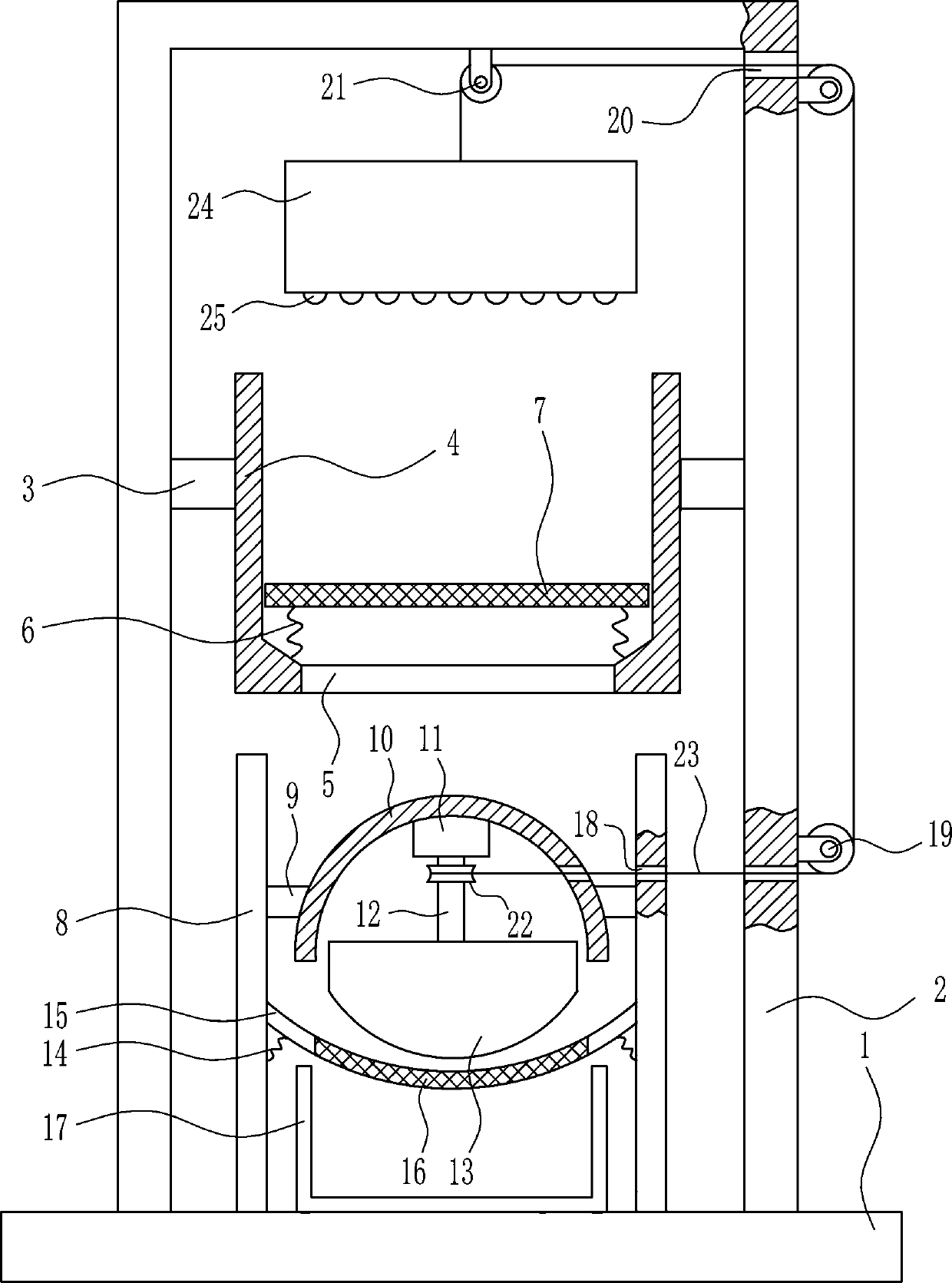

[0028] A corn multi-stage crushing equipment for pig feed preparation, such as Figure 1-5 As shown, it includes a mounting plate 1, a mounting frame 2, a pole 3, a frame body 4, a first spring 6, a first mesh plate 7, a connecting plate 8, a connecting rod 9, an arc-shaped mounting frame 10, a motor 11, and a rotating shaft 12. Grinding block 13, second spring 14, arc-shaped plate 15, arc-shaped net plate 16, collection frame 17, first fixed pulley 19, second fixed pulley 21, winding wheel 22, first pull wire 23, broken block 24 and crushing teeth 25, mounting plate 1 is provided with mounting frame 2, mounting frame 2 is provided with struts 3 on the inside upper part of the left and right sides of the wall, frame body 4 is connected between the struts 3 inboards, and frame body 4 bottom center is provided with The discharge hole 5, the bottom of the frame body 4 is symmetrically provided with the first spring 6, the top of the first spring 6 is connected with the first mesh...

Embodiment 2

[0030] A corn multi-stage crushing equipment for pig feed preparation, such as Figure 1-5 As shown, it includes a mounting plate 1, a mounting frame 2, a pole 3, a frame body 4, a first spring 6, a first mesh plate 7, a connecting plate 8, a connecting rod 9, an arc-shaped mounting frame 10, a motor 11, and a rotating shaft 12. Grinding block 13, second spring 14, arc-shaped plate 15, arc-shaped net plate 16, collection frame 17, first fixed pulley 19, second fixed pulley 21, winding wheel 22, first pull wire 23, broken block 24 and crushing teeth 25, mounting plate 1 is provided with mounting frame 2, mounting frame 2 is provided with struts 3 on the inside upper part of the left and right sides of the wall, frame body 4 is connected between the struts 3 inboards, and frame body 4 bottom center is provided with The discharge hole 5, the bottom of the frame body 4 is symmetrically provided with the first spring 6, the top of the first spring 6 is connected with the first mesh...

Embodiment 3

[0033] A corn multi-stage crushing equipment for pig feed preparation, such as Figure 1-5 As shown, it includes a mounting plate 1, a mounting frame 2, a pole 3, a frame body 4, a first spring 6, a first mesh plate 7, a connecting plate 8, a connecting rod 9, an arc-shaped mounting frame 10, a motor 11, and a rotating shaft 12. Grinding block 13, second spring 14, arc-shaped plate 15, arc-shaped net plate 16, collection frame 17, first fixed pulley 19, second fixed pulley 21, winding wheel 22, first pull wire 23, broken block 24 and crushing teeth 25, mounting plate 1 is provided with mounting frame 2, mounting frame 2 is provided with struts 3 on the inside upper part of the left and right sides of the wall, frame body 4 is connected between the struts 3 inboards, and frame body 4 bottom center is provided with The discharge hole 5, the bottom of the frame body 4 is symmetrically provided with the first spring 6, the top of the first spring 6 is connected with the first mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com