Liquid parallel flow composite tower

A composite column and liquid technology, which is applied in the preparation of hydroxyl compounds, organic compounds, organic chemistry, etc., can solve the problem of lower separation efficiency and reflux ratio of parallel flow trays, problems of equipment and technical economy, and inability to fully display separation efficiency, etc. problems, to achieve the effect of reducing the diameter of the tower body, increasing the effective mass transfer area, and improving the mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

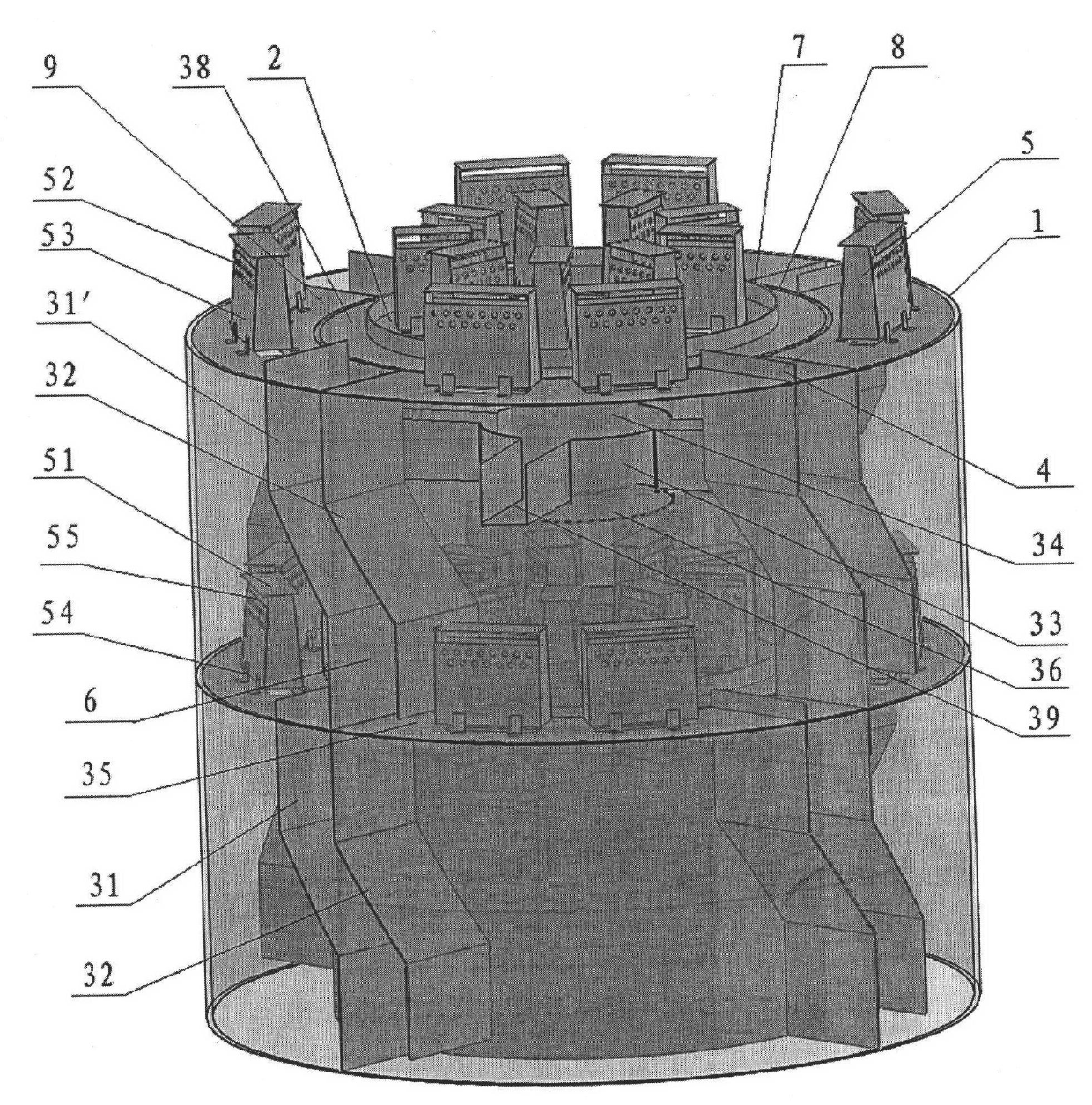

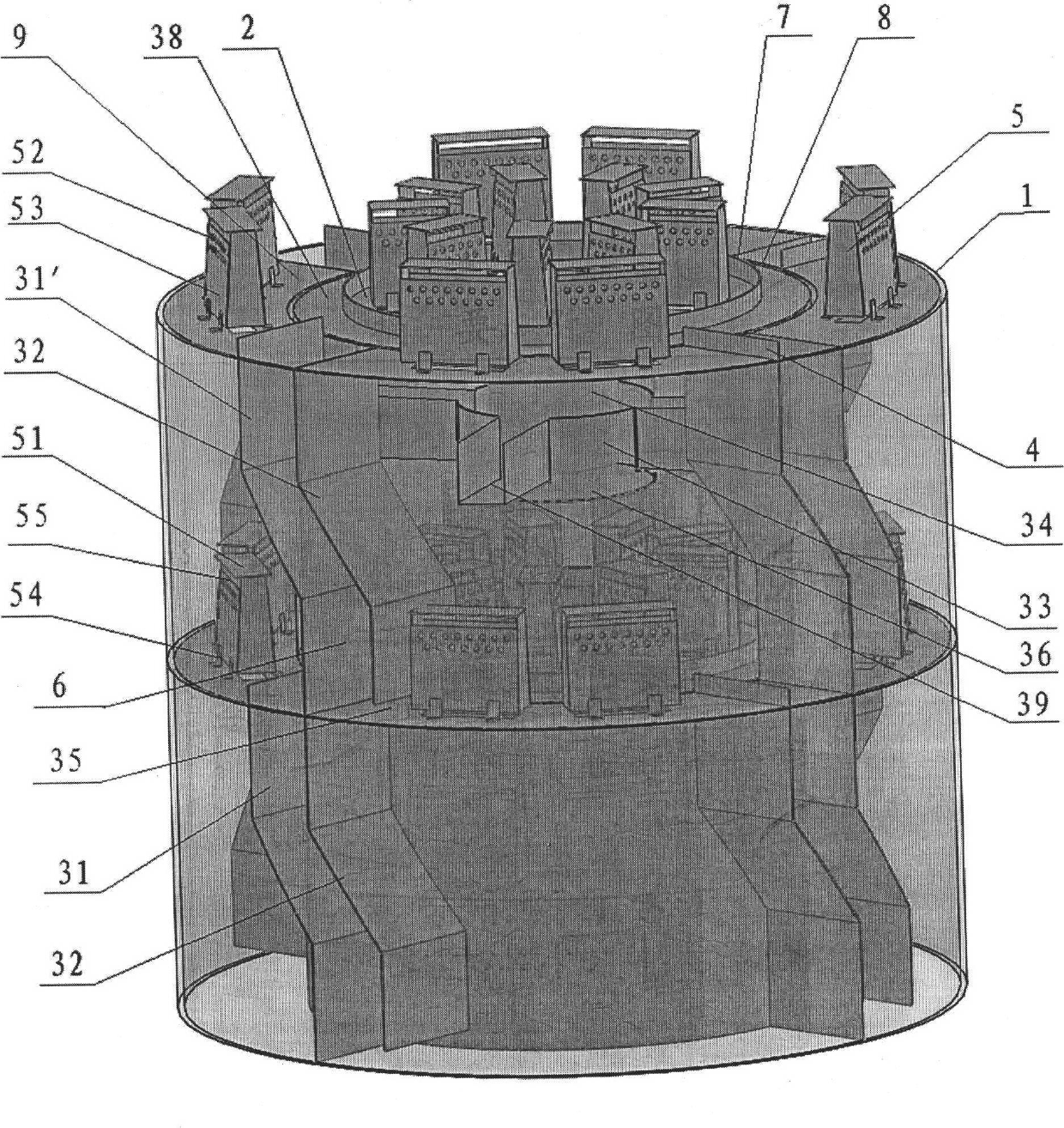

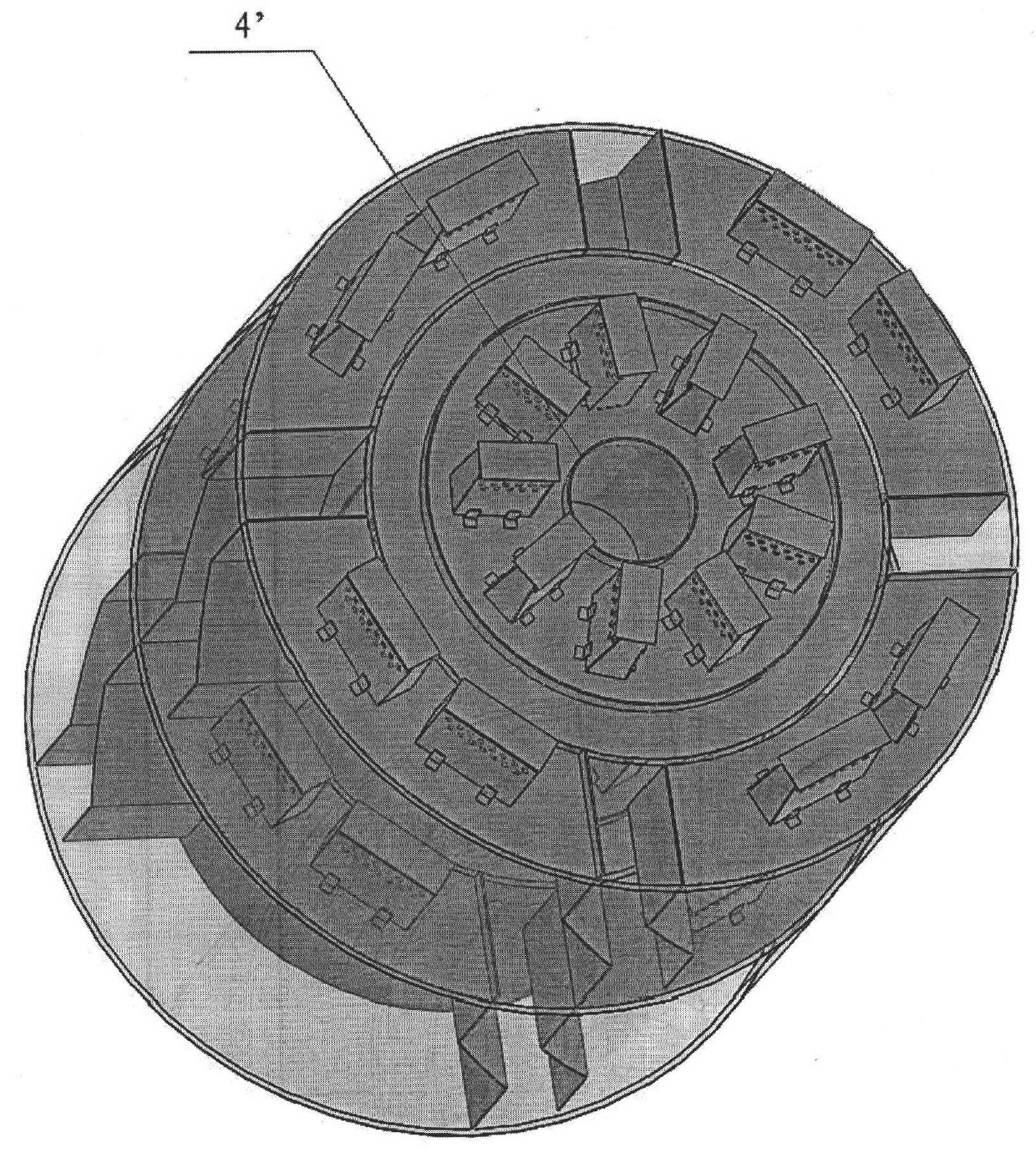

[0024] figure 1 It is a liquid co-current composite tower, comprising a cylindrical tower body 1 and a multi-layer continuous mass transfer tray arranged in the tower body 1, the tower body is divided into a cylindrical inner tower 8 and an annular outer tower 9, and the inner tower is sleeved outside. In the tower, the plate I 2 in the inner tower corresponds to the cross section of the inner tower and is arranged in parallel, and the outer tower is also arranged in parallel with the annular tower II 2' corresponding to the cross section of the outer tower; There is a drop system.

[0025] The downcomer system of the outer tower includes four sets of downcomers arranged alternately around the interior of the outer tower, and the four sets of downcomers divide the entire outer tower II into four parts, (of course, the downcomers can al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com