Method for preparing silk fibroin three-dimensional porous material

A technology of silk fibroin and porous material, which is applied in medical science, prosthesis, etc., can solve the problem that the proportion of silk fibroin I and silk fibroin II cannot be adjusted, and achieve the effect of good structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Soak about 50g raw silk in 2L 0.5% Na 2 CO 3 solution, stirred and boiled for 30 minutes, then removed and washed with deionized water. After repeating the above operation twice, the silk was dried at 60°C.

[0039] 15 g of the degummed silk after the above treatment was weighed and dissolved in 100 ml of BrLi solution with a concentration of 9.5 mol / L, stirred and dissolved at 60° C. for one hour. Then use a dialysis bag with a molecular weight cut-off of 3500 to dialyze with deionized water for four days to obtain a silk protein aqueous solution with a concentration of 4%, and adjust the concentration of the silk protein aqueous solution to 2%.

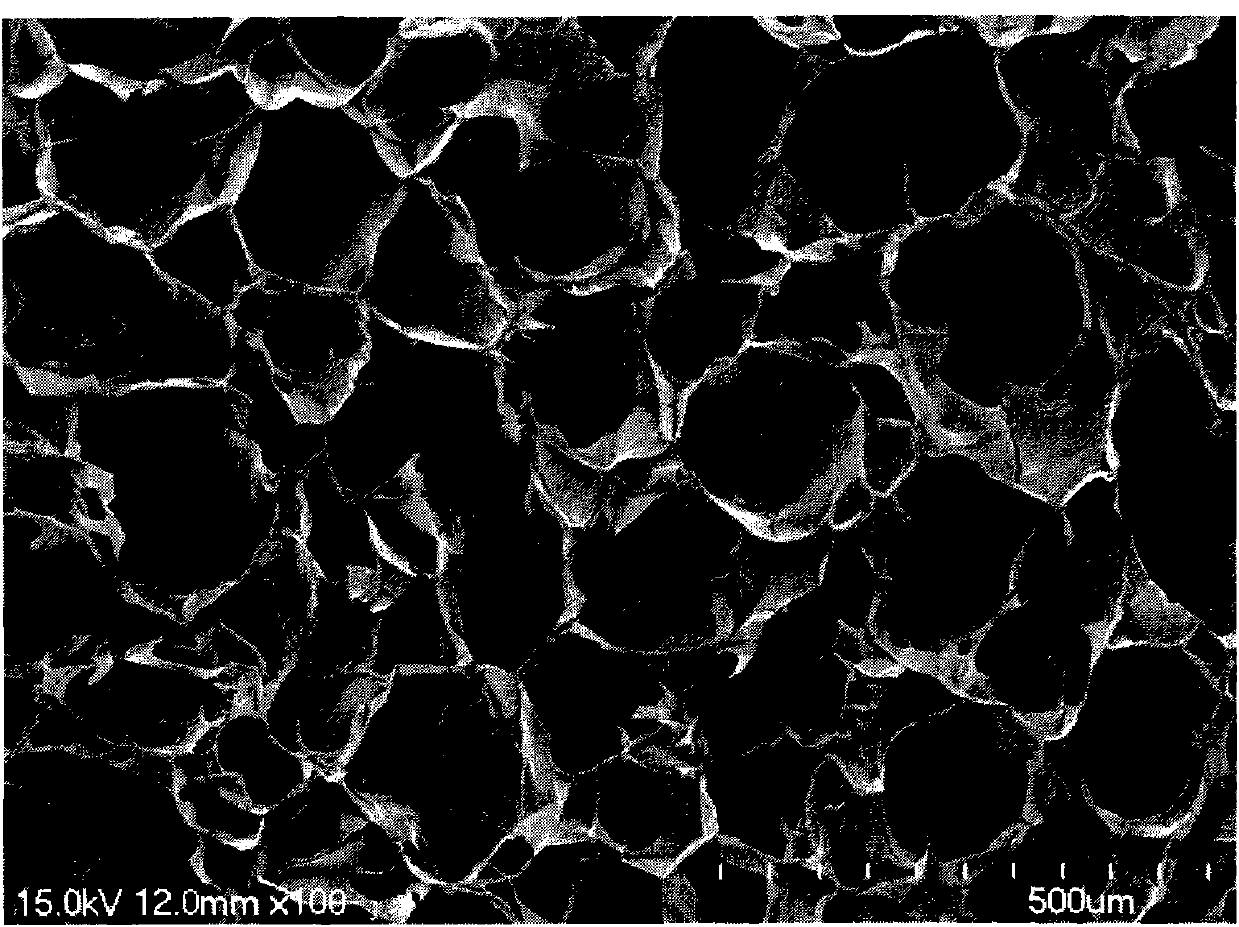

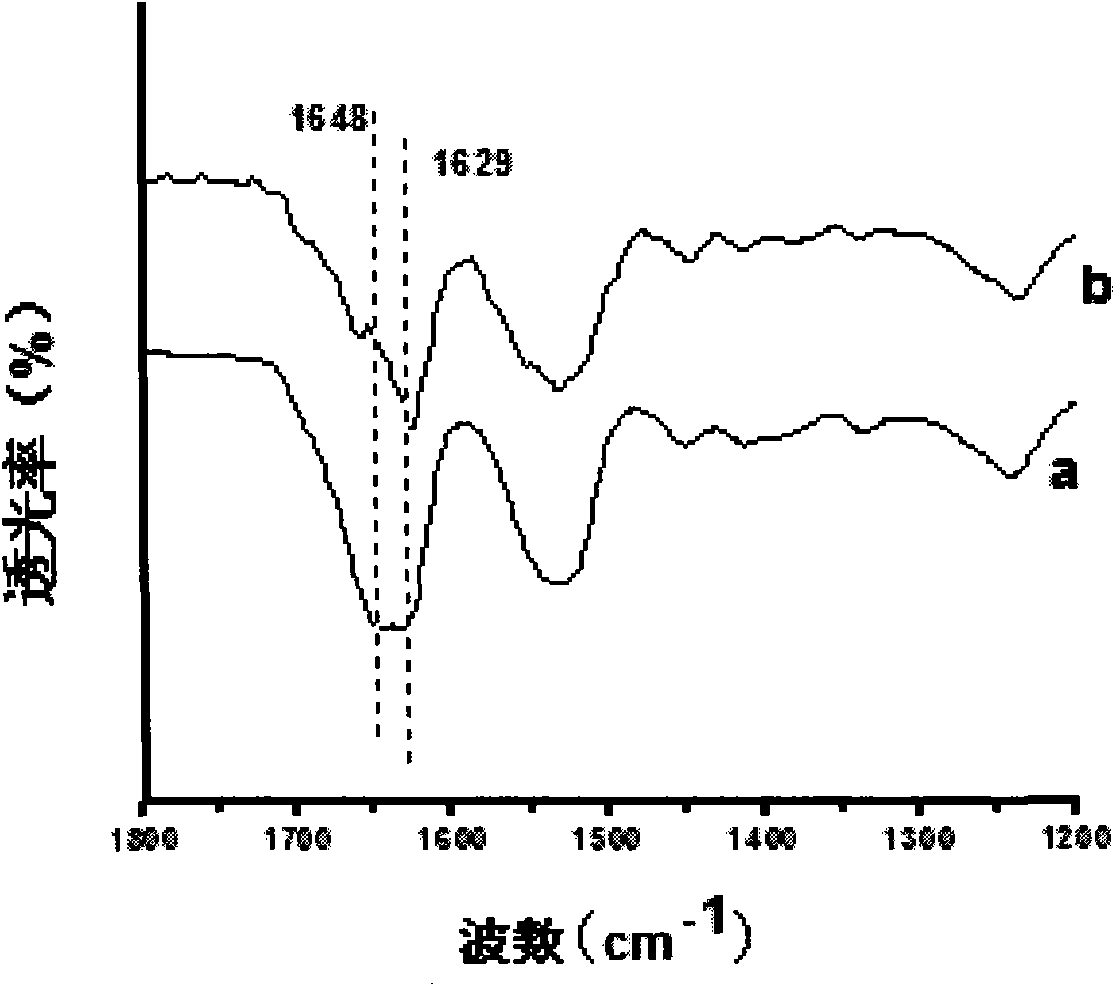

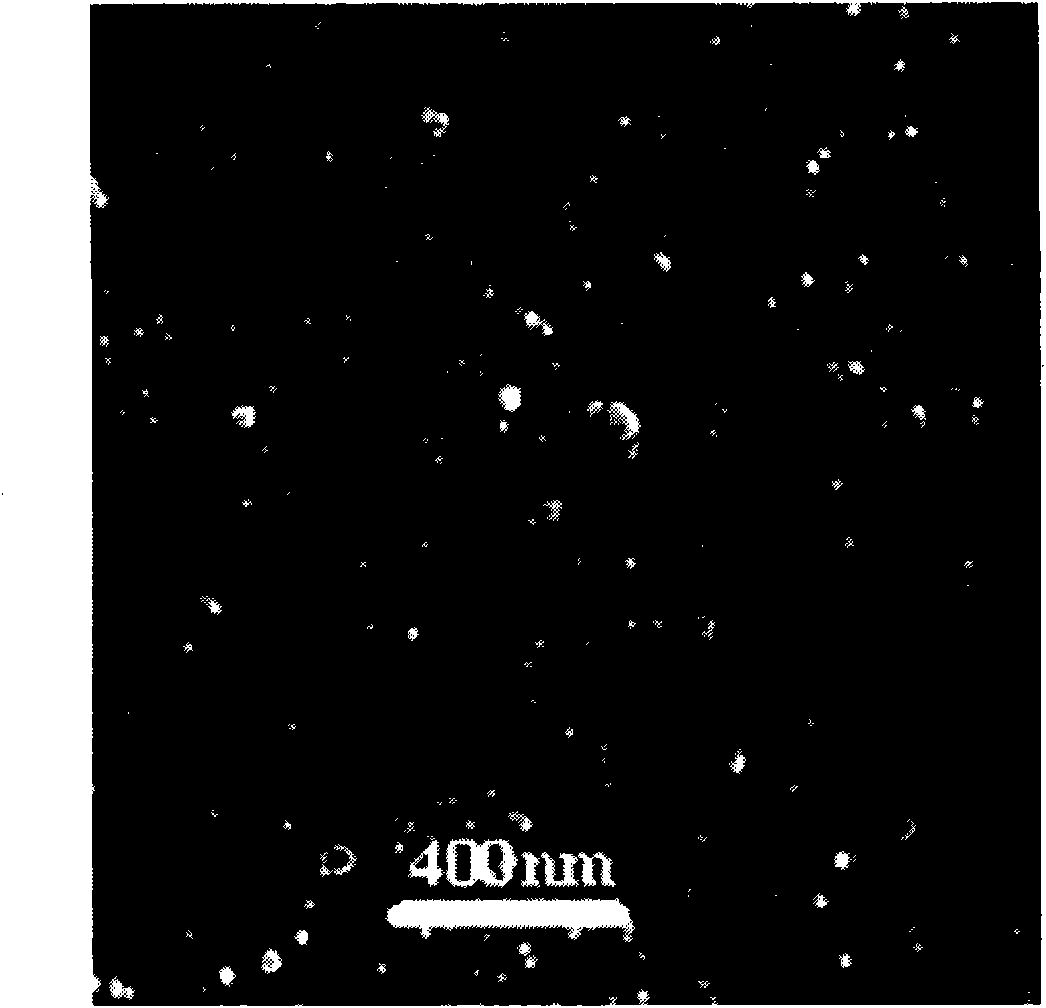

[0040] Take 15mL of the above-mentioned silk protein solution, and adjust the concentration speed by reducing the volatilization area of the solution under the condition of 60°C. After concentration for 48 hours, the concentration is about 30%. After concentration, an aqueous solution of silk fibroin nanowires is obtained...

Embodiment 2

[0043] Soak about 50g raw silk in 2L 0.5% Na 2 CO 3 solution, stirred and boiled for 30 minutes, then removed and washed with deionized water. After repeating the above operation twice, the silk was dried at 60°C.

[0044] 15 g of the degummed silk after the above treatment was weighed and dissolved in 100 ml of BrLi solution with a concentration of 9.5 mol / L, stirred and dissolved at 60° C. for one hour. Then use a dialysis bag with a molecular weight cut-off of 3500 to dialyze with deionized water for four days to obtain a silk protein aqueous solution with a concentration of 4%, and adjust the concentration of the silk protein aqueous solution to 2%.

[0045] Take 15mL of the above silk protein solution, and adjust the concentration speed by reducing the volatilization area of the solution under the condition of 60°C. After concentration for 48 hours, the concentration is about 30%. After concentration, the aqueous solution of silk fibroin nanowires is obtained; the sol...

Embodiment 3

[0049] Soak about 50g raw silk in 2L 0.5% Na 2 CO 3 solution, stirred and boiled for 30 minutes, then removed and washed with deionized water. After repeating the above operation twice, the silk was dried at 60°C.

[0050] 15 g of the degummed silk after the above treatment was weighed and dissolved in 100 ml of BrLi solution with a concentration of 9.5 mol / L, stirred and dissolved at 60° C. for one hour. Then use a dialysis bag with a molecular weight cut-off of 3500 to dialyze with deionized water for four days to obtain a silk protein aqueous solution with a concentration of 4%, and adjust the concentration of the silk protein aqueous solution to 2%.

[0051] Take 15mL of the above silk protein solution, and adjust the concentration speed by reducing the volatilization area of the solution under the condition of 60°C. After concentration for 48 hours, the concentration is about 30%. After concentration, the aqueous solution of silk fibroin nanowires is obtained; the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com