Particulate filtration device

A filter device and particle technology, applied in the direction of dispersed particle filtration, membrane filter, noise reduction device, etc., can solve the problem of poor regeneration process of the filter, and achieve the effect of simple and compact filter design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

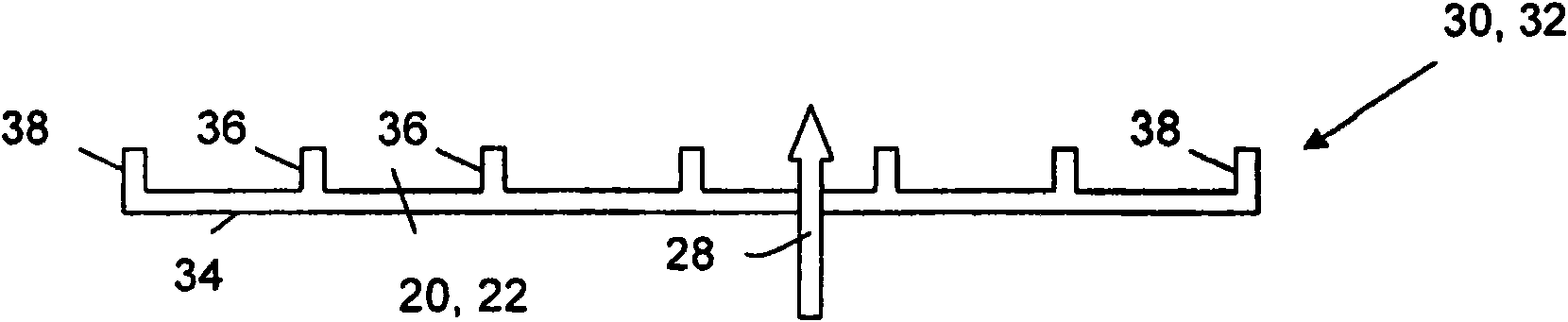

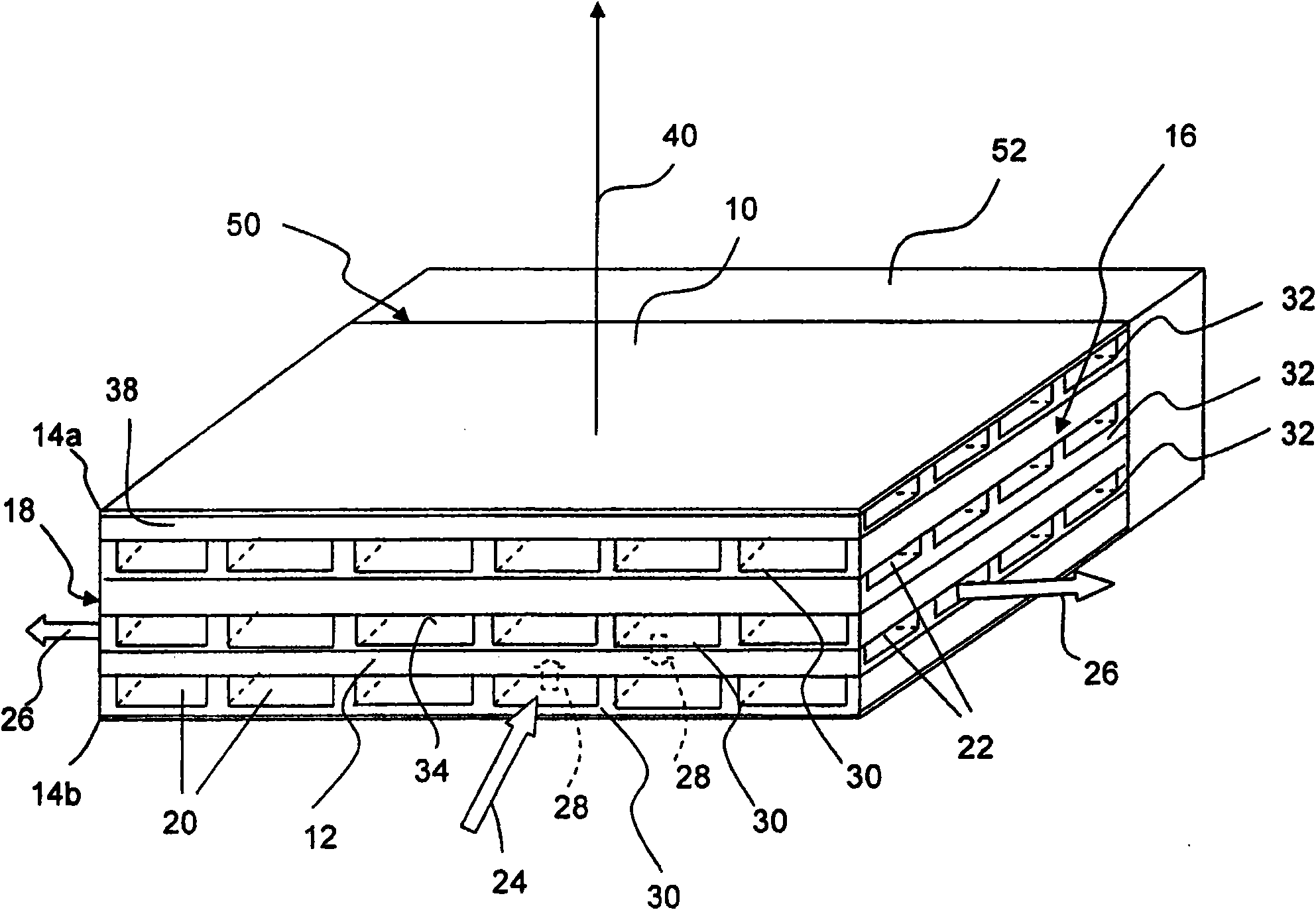

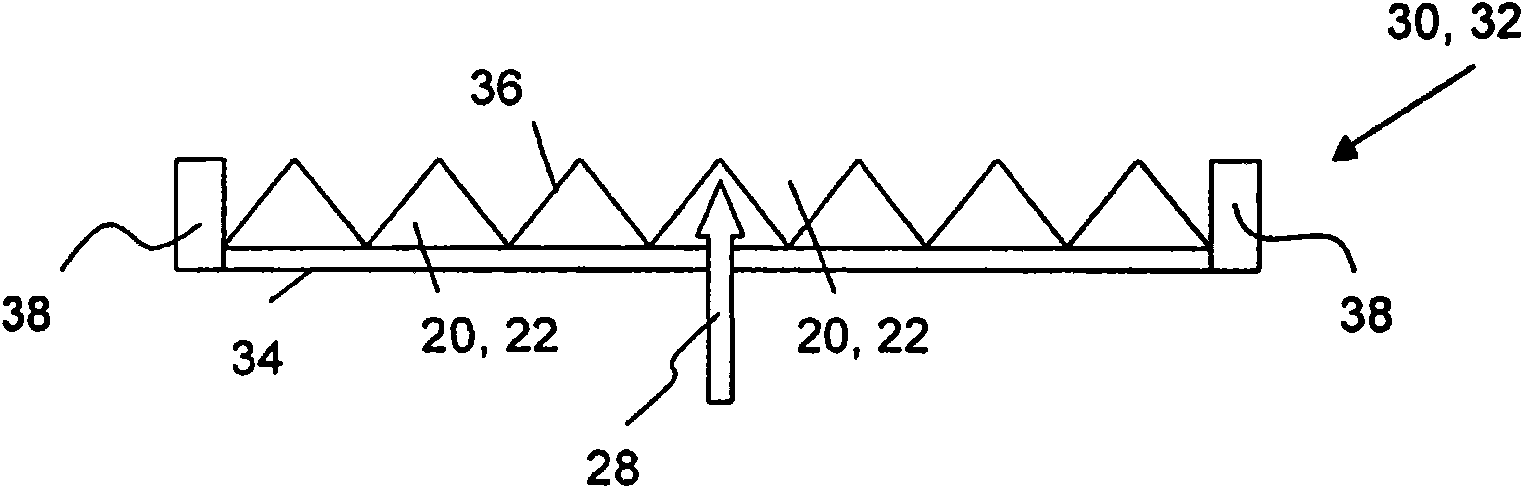

[0033] Figure 1a and Figure 1b A preferred filter 10 of a filter device (not shown) according to the invention is depicted in . The filter 10 has a feed inlet side 12 for the feed gas and filtrate outlets 16 , 18 for the filtrate. For example, in the case of raw exhaust gas as the feed fluid, the filter is exhaust gas free of carbon particles. The feed gas flows along the feed gas channels 20 arranged in the feed gas plate 30 , and the filtrate flows along the filtrate channels 22 arranged in the filtrate channel plate 32 . The plates 30 , 32 are stacked on top of each other in an alternating manner in the stacking direction 40 and are separated by a gas-permeable membrane 34 , wherein the channels 20 , 22 of successive channel plates 30 , 32 are arranged orthogonally, ie as Figure 1a As shown, the plates 30, 32 are rotated 90 degrees within each stacked layer.

[0034] The plates 30 , 32 have a comb-like shape with separator walls 36 (only a few are indicated with their ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com