Permanent magnet safe brake with high friction coefficient

A technology of power-off brake and high friction coefficient, applied in the direction of brake type, axial brake, brake components, etc., can solve the problems of short service life and high noise of the brake, and achieve reliable operation, noise reduction, and easy implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

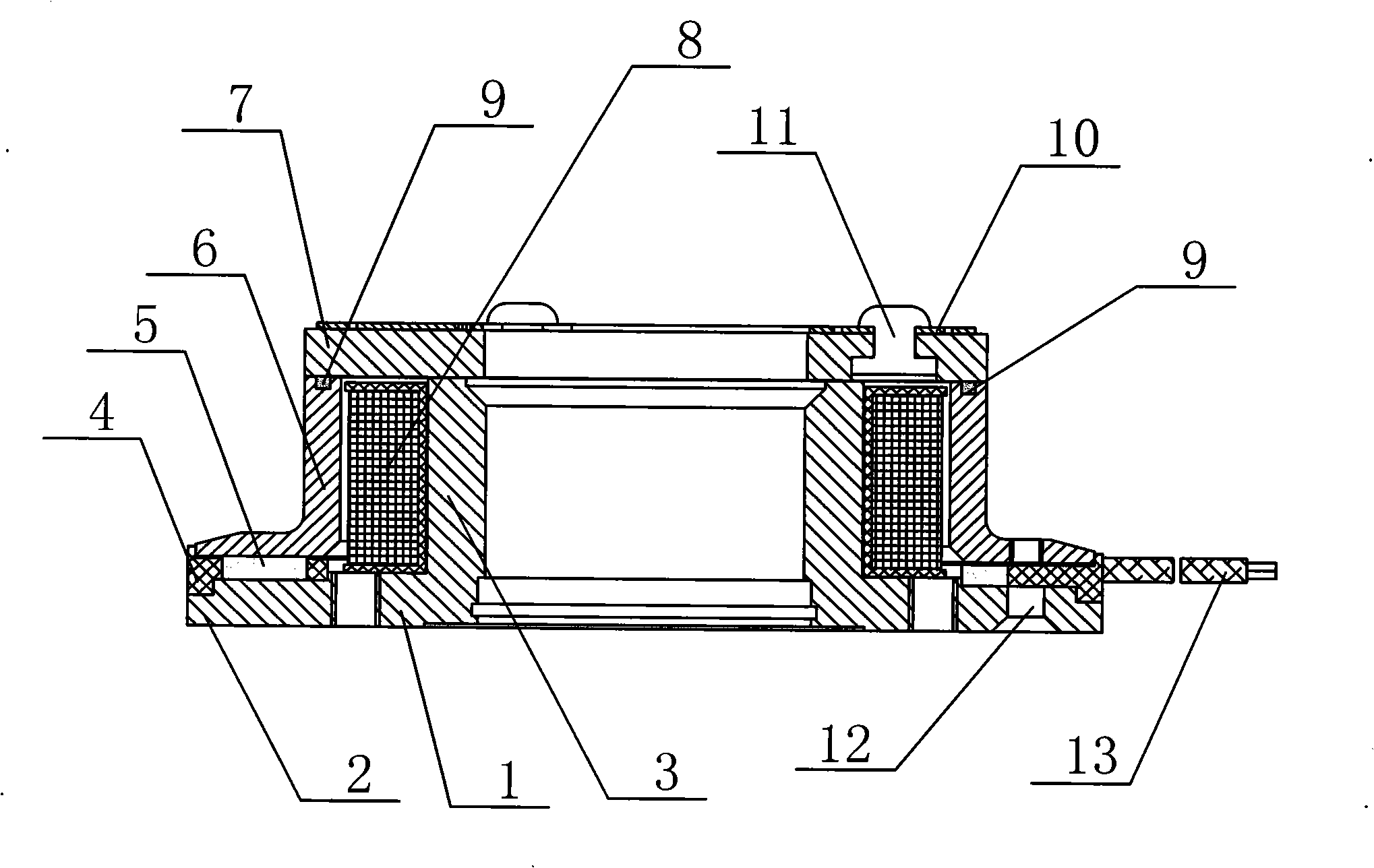

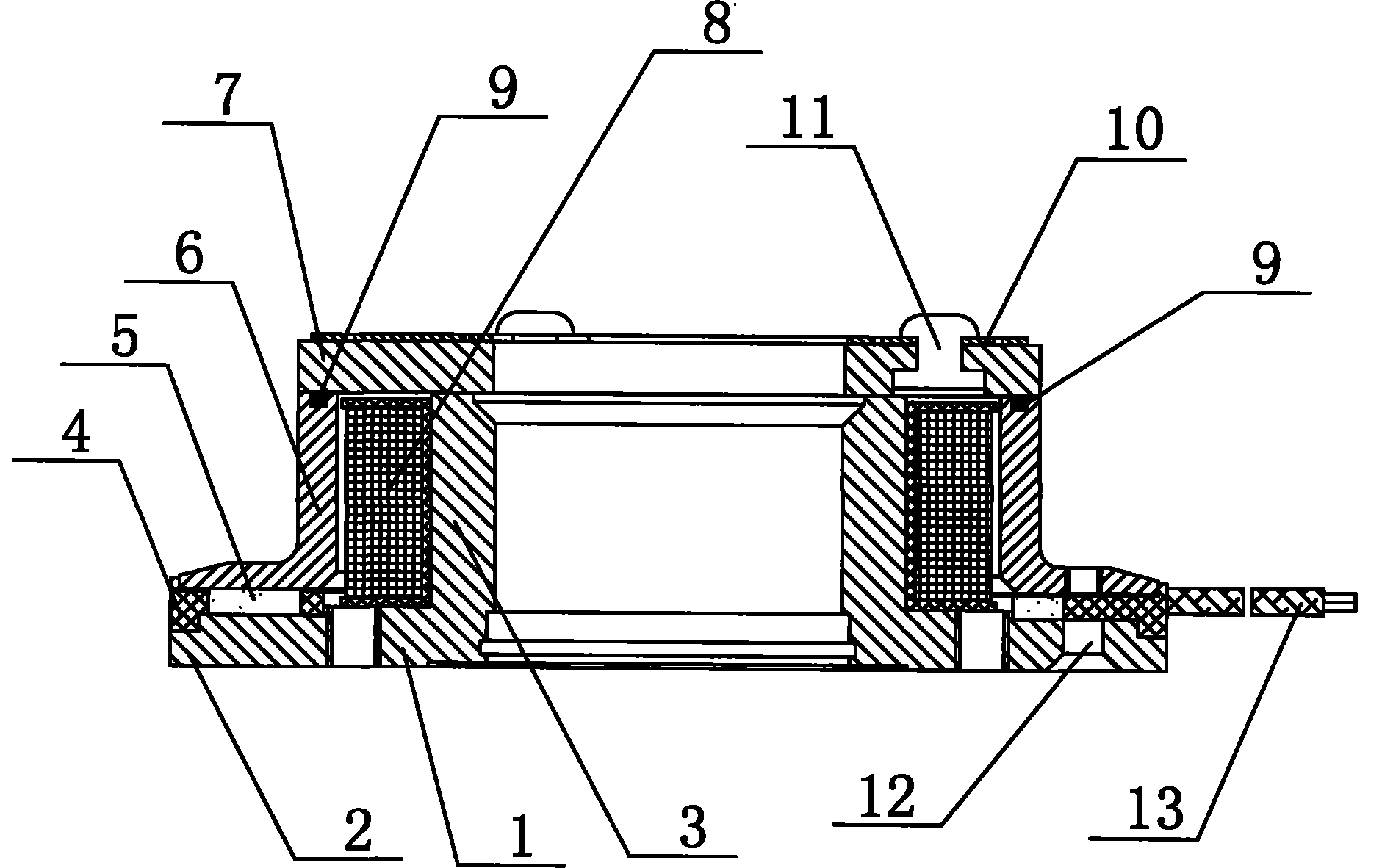

[0014] Please refer to figure 1 as shown, figure 1 It is a schematic structural diagram of a permanent magnet power-off brake with a high friction coefficient of the present invention. In this embodiment, a permanent magnet power-off brake includes a base 1, and the base 1 includes a permanent magnet steel mounting part 2 and The electrified excitation magnetic coil installation part 3, the electrified excitation magnetic coil installation part 3 is a cylindrical structure, one end of which extends to the periphery a permanent magnet steel installation part 2, and the permanent magnet steel installation part 2 is provided with a magnetic steel skeleton 4. The magnetic steel skeleton 4 is provided with a plurality of magnetic steel installation holes (not shown in the figure), and the magnetic steel installation holes are circular in structure, and a circular permanent magnetic steel 5 is installed in it, and the charged The exciting magnetic coil installation part 3 is covere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com