Method for building harbor wharf based on soft soil

A wharf and seaport technology, applied in the field of hydraulic structures, can solve the problems of processing and manufacturing, difficulty in transportation, positioning and installation, high cost of seaports and wharfs, and long construction period, and achieve high construction safety efficiency, low cost, and short construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

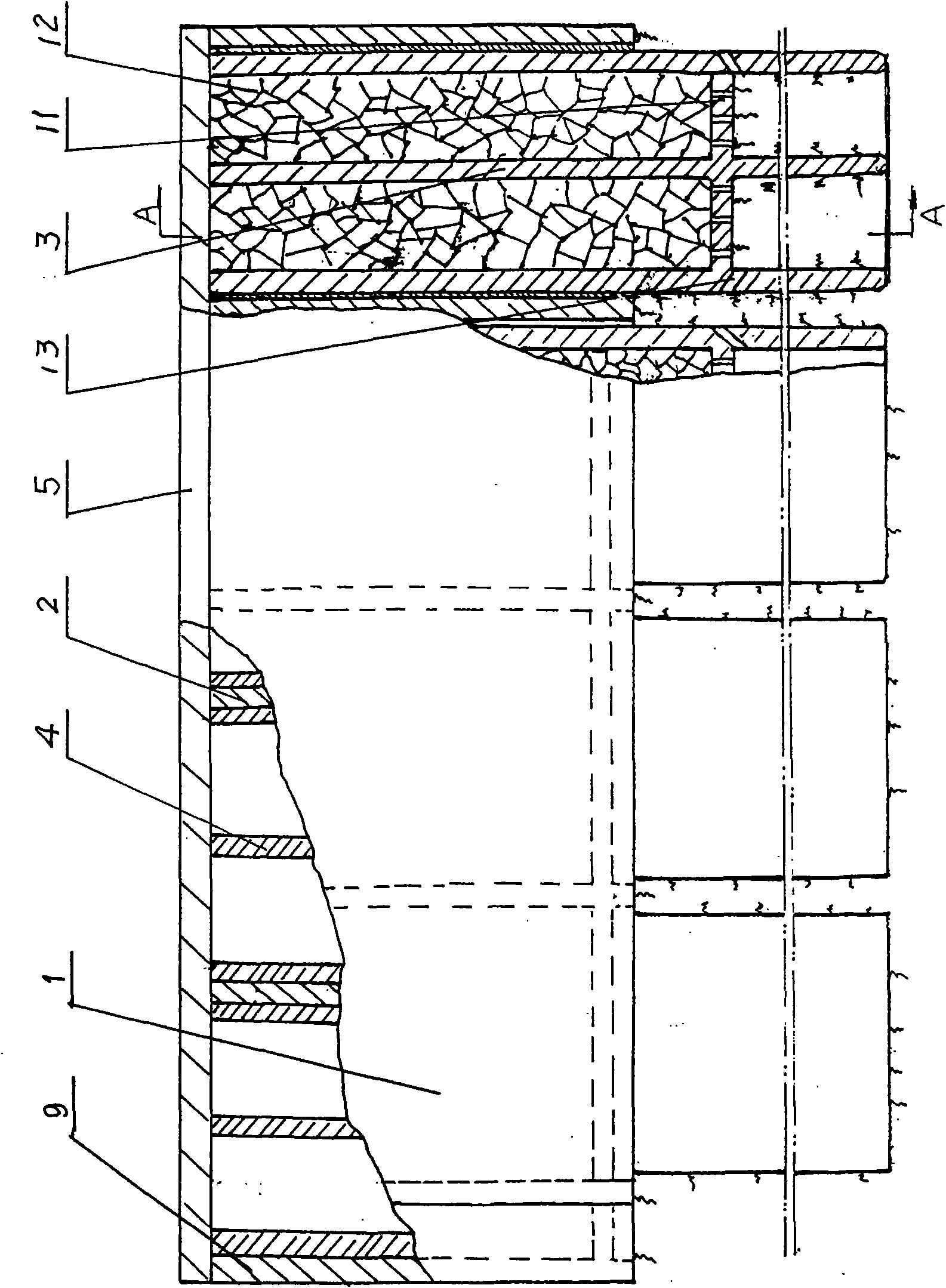

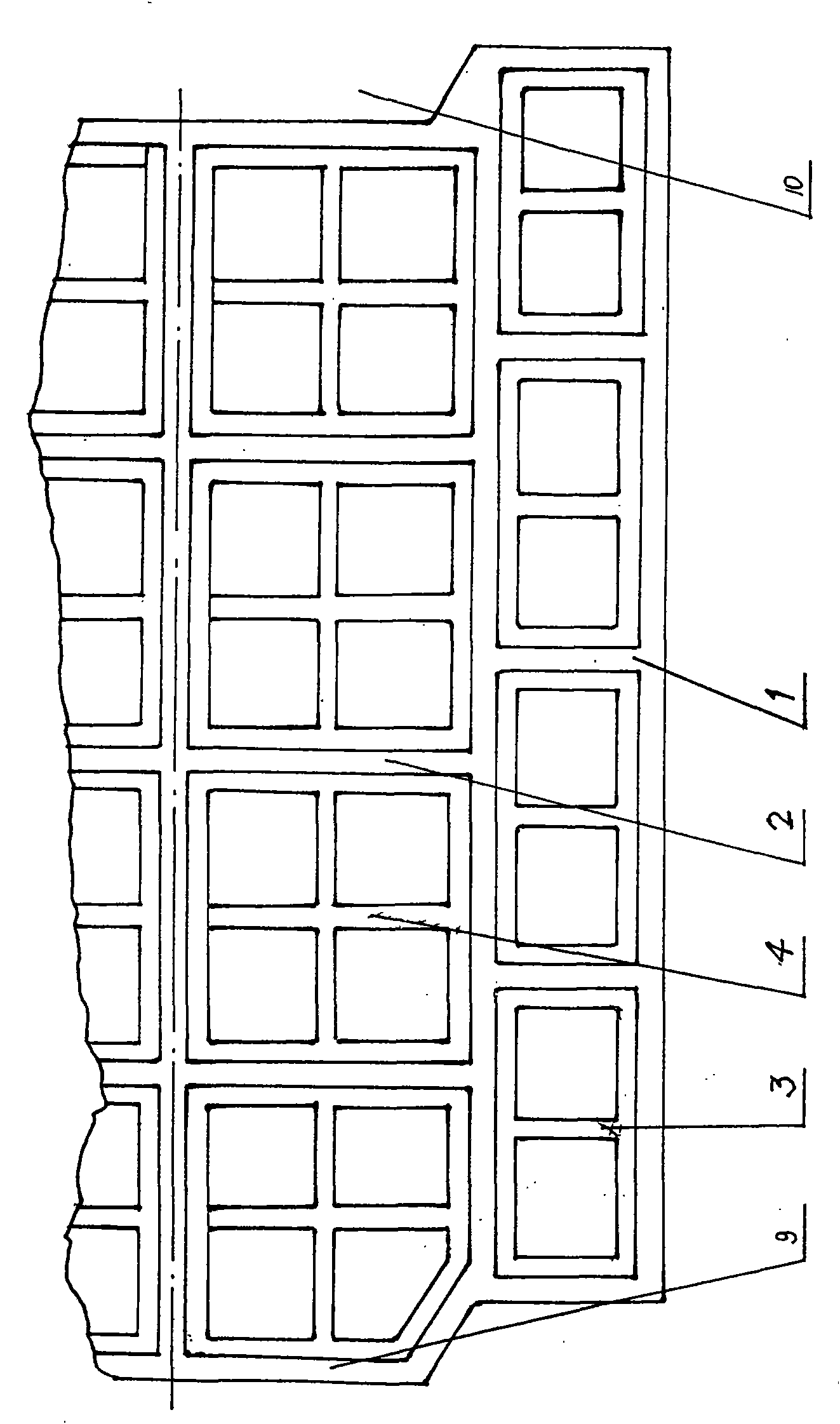

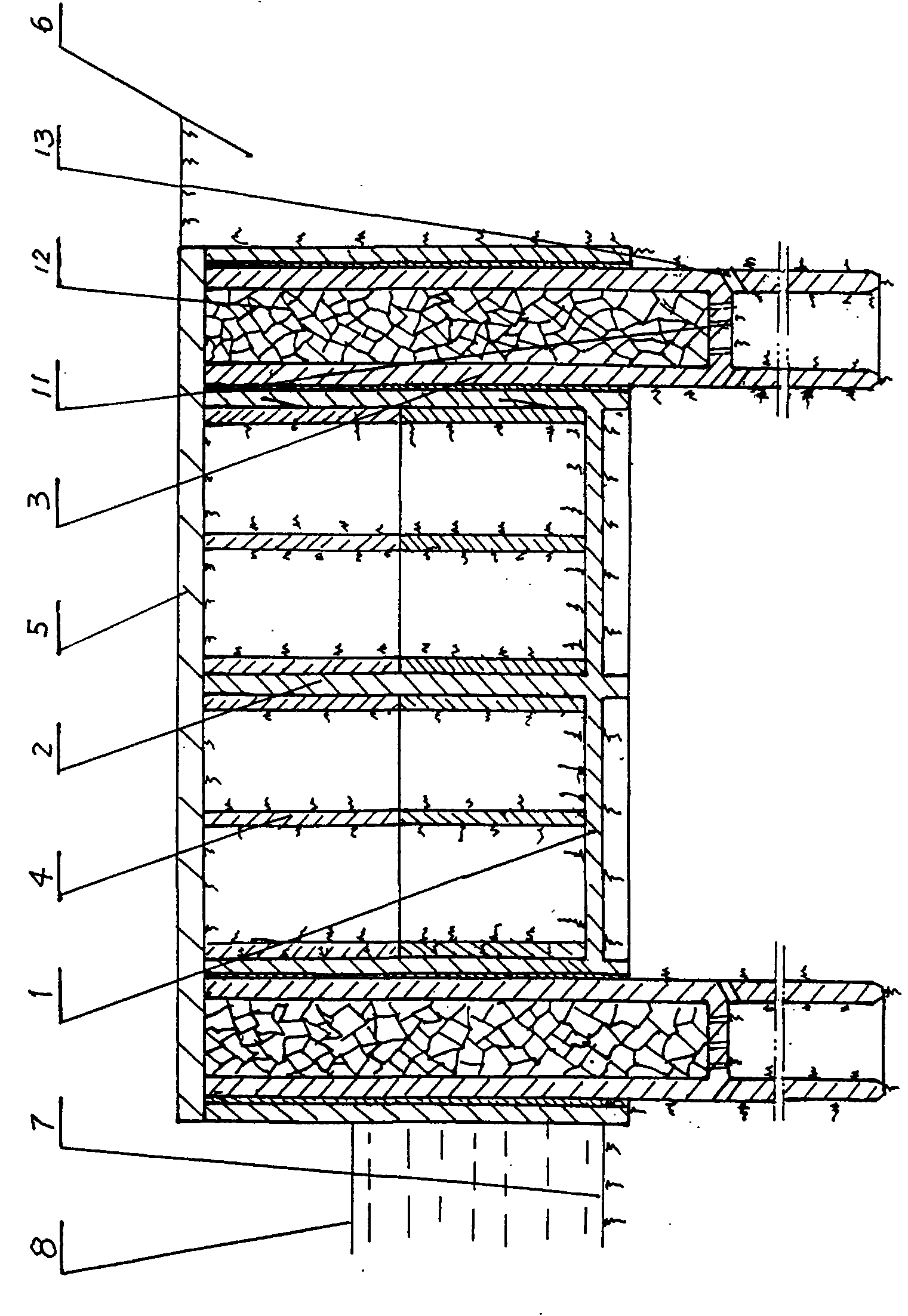

[0045] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail: figure 1 , figure 2 , image 3 It is the first type of embodiment of the present invention, and the first type of embodiment is used for constructing a harbor wharf.

[0046] figure 1 It is the front view of the construction of the caisson platform of the harbor wharf on the soft soil foundation. figure 2 It is a top view of the construction of the caisson platform of the harbor wharf on the soft soil foundation. image 3 yes figure 1 A-A cutaway view.

[0047] Depend on figure 1 , figure 2 , image 3 It can be seen from the figure that the caisson platform 1 is a rectangular reinforced concrete box surrounded by four vertical sides and a horizontal bottom surface, the two sides in the length direction of the caisson platform are the connecting end surfaces of the caisson platform, and the two One side is the side facing the sea, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com