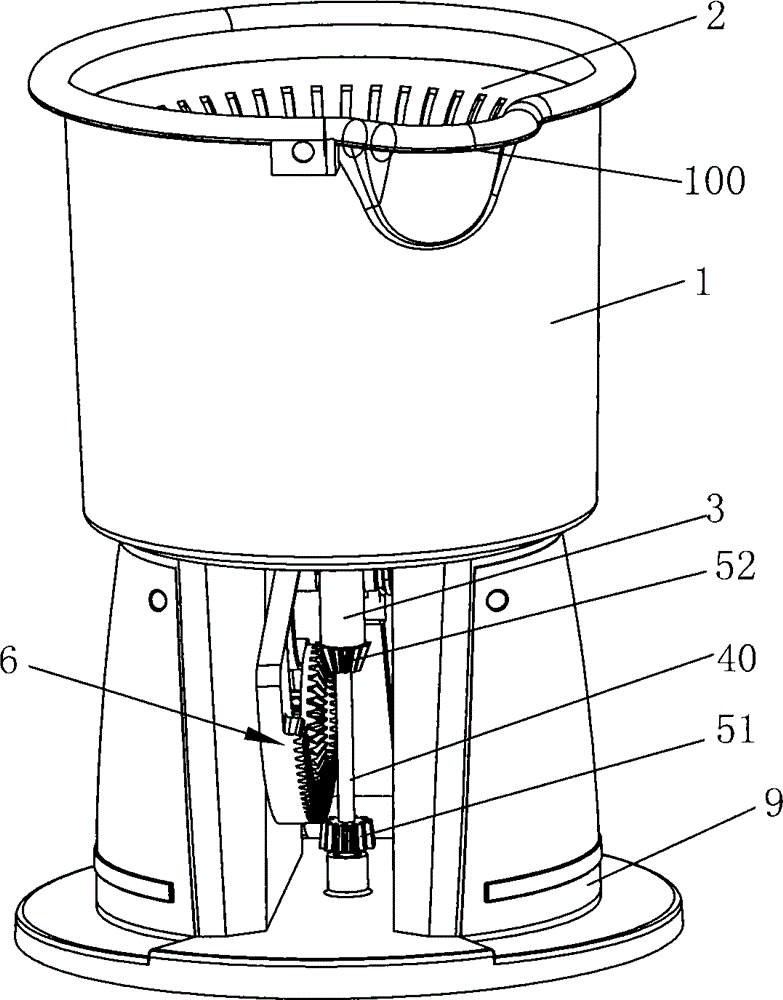

Treadle sports type impeller type washing machine

A pulsator washing machine and a sports-type technology, applied in the field of washing machines, can solve the problems of complex structure, high maintenance rate, easy damage, etc., and achieve the effect of low rotation speed and high rotation speed in the dehydration process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

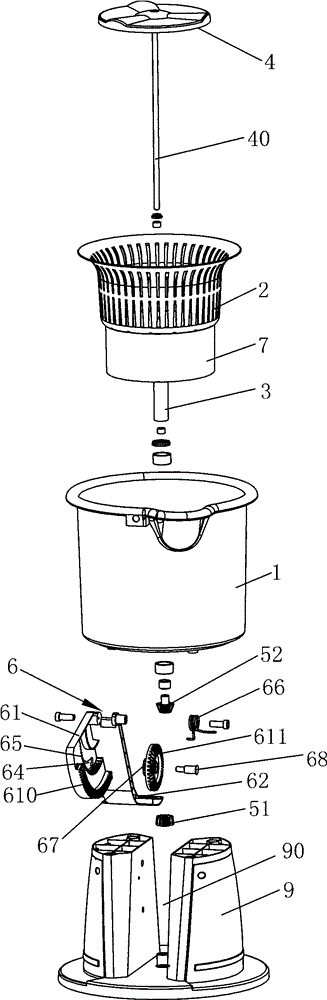

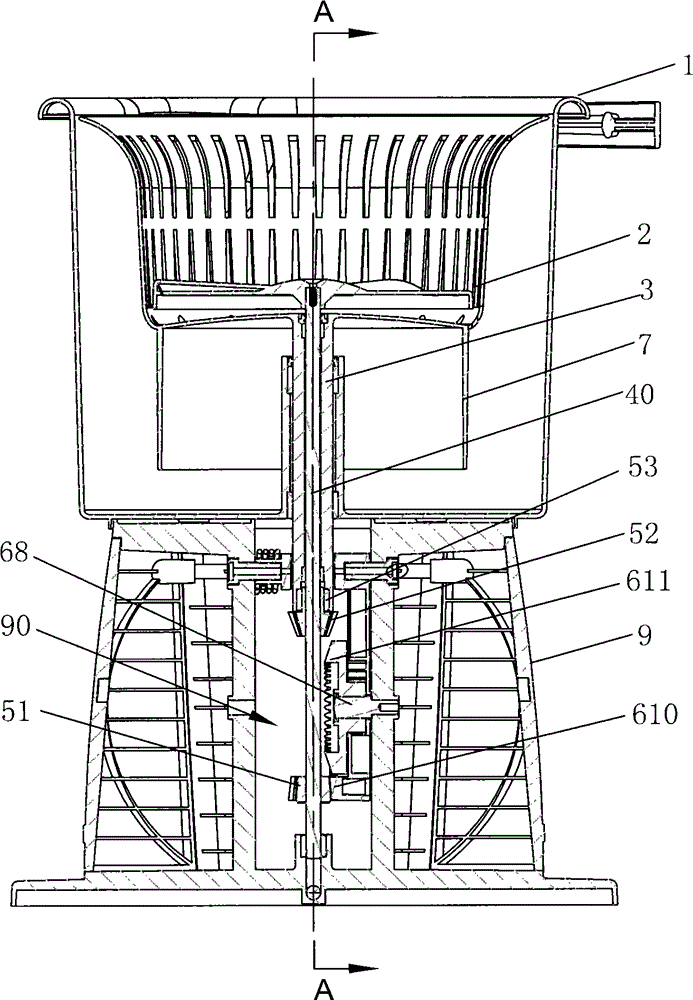

[0040] like Figure 1 to Figure 6 As shown, the pedal device 6 described in this embodiment includes an arc-shaped plate 61, a pedal 62 integrated with the arc-shaped plate 61 and extending outward along its radius, and a reset torsion spring 66. The base 9 is provided with a The external vertical opening 90, the arc plate 61 is pivotally erected in the opening 90, and the center of rotation is the center of the arc plate, which can be rotated back and forth in the opening direction by pedals and torsion springs, similar to swinging. The pedal 62 extends from the opening 90 to the outside of the base 9. The driving bevel teeth include a first driving bevel tooth 611 that can engage with the dehydration bevel teeth and a second drive bevel tooth 610 that can engage with the washing bevel teeth. The arc-shaped plate 61 of the arc-shaped plate 61 is provided with an obliquely downward second drive bevel tooth 610 along the circumference, and the second drive bevel tooth 610 can m...

Embodiment 2

[0044] like Figure 7 As shown, the pedal device 6 described in this embodiment includes an arc-shaped plate 61, a pedal 62 integrated with the arc-shaped plate 61 and extending outward along its radius, and a reset torsion spring. The base 9 is provided with a pair of outer The opening in the vertical direction, the pivot of the arc-shaped plate is erected in the opening, and the center of rotation is the center of the arc-shaped plate. It can rotate back and forth in the direction of the opening by relying on the foot pedal and the torsion spring reset, similar to swinging. The pedal 62 is formed by The opening extends to the outside of the base 9; the arc-shaped plate 61 has an arc-shaped groove 64 parallel to the circumference, and the arc-shaped groove 64 is provided with an inner rack 65 along the outer edge of the arc-shaped edge, corresponding to the pivot of the inner rack 65 A double gear is provided, and the rotating shaft of the double gear passes through the arc g...

Embodiment 3

[0047] like Figure 8 As shown, the pedal device 6 described in this embodiment includes an arc-shaped plate 61, a pedal 62 integrated with the arc-shaped plate 61 and extending outward along its radius, and a reset torsion spring 66. The base 9 is provided with a For the opening in the vertical direction to the outside, the arc-shaped plate is arranged in the opening, and can rotate back and forth in the direction of the opening by relying on the pedal and the torsion spring to reset, similar to swinging, the pedal 62 extends from the opening to the outside of the base 9, the above-mentioned The structure is the same as that of Embodiment 1; the drive bevel tooth includes a first drive bevel tooth 611 that can engage with the dehydration bevel tooth and a second drive bevel tooth 610 that can engage with the washing bevel tooth, and the arc plate 61 is arranged along the circumference There is an obliquely downward second drive bevel tooth 610, the second drive bevel gear 610...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com