Preparation method and application of macroporous polyacryamide resin

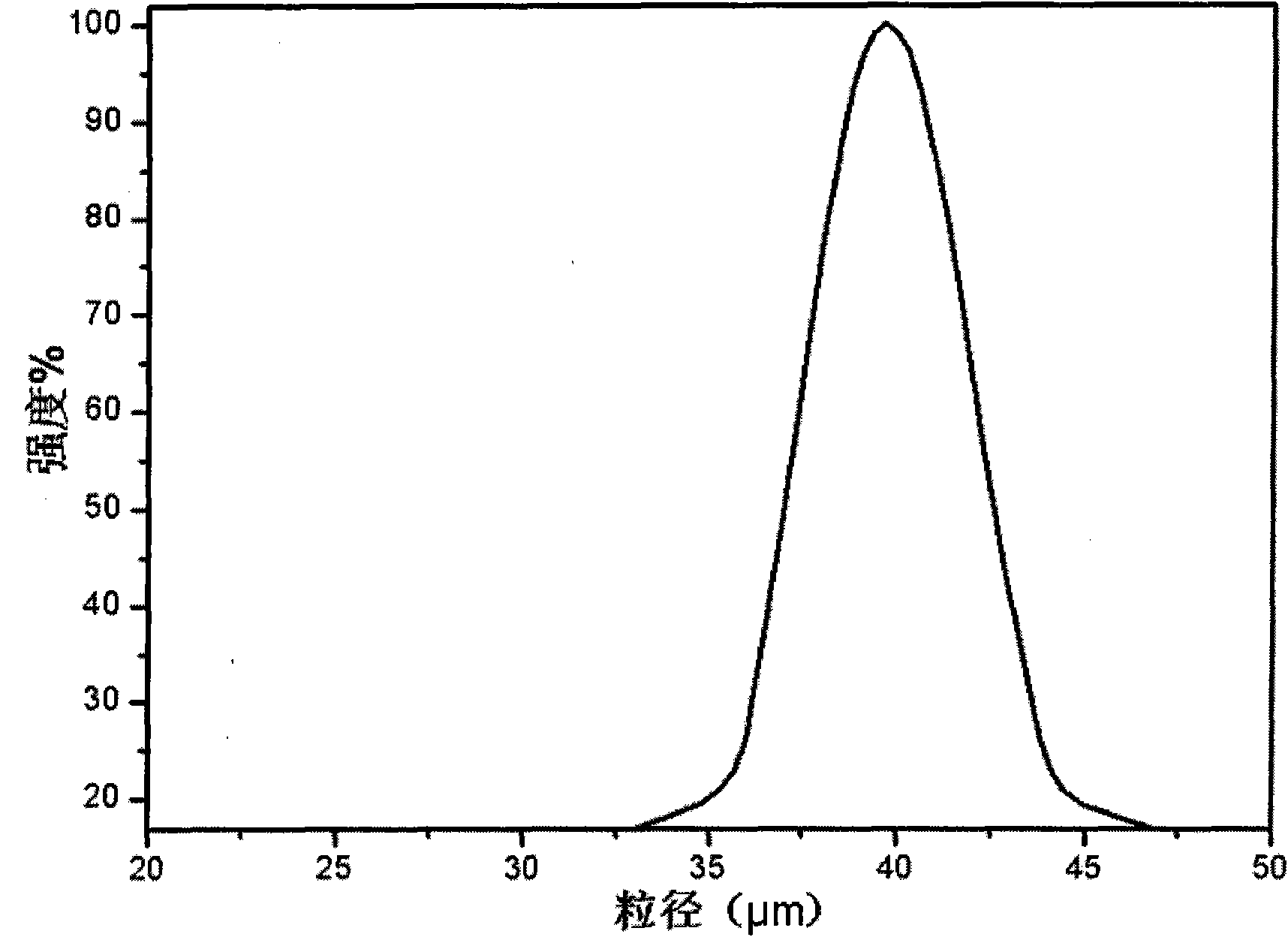

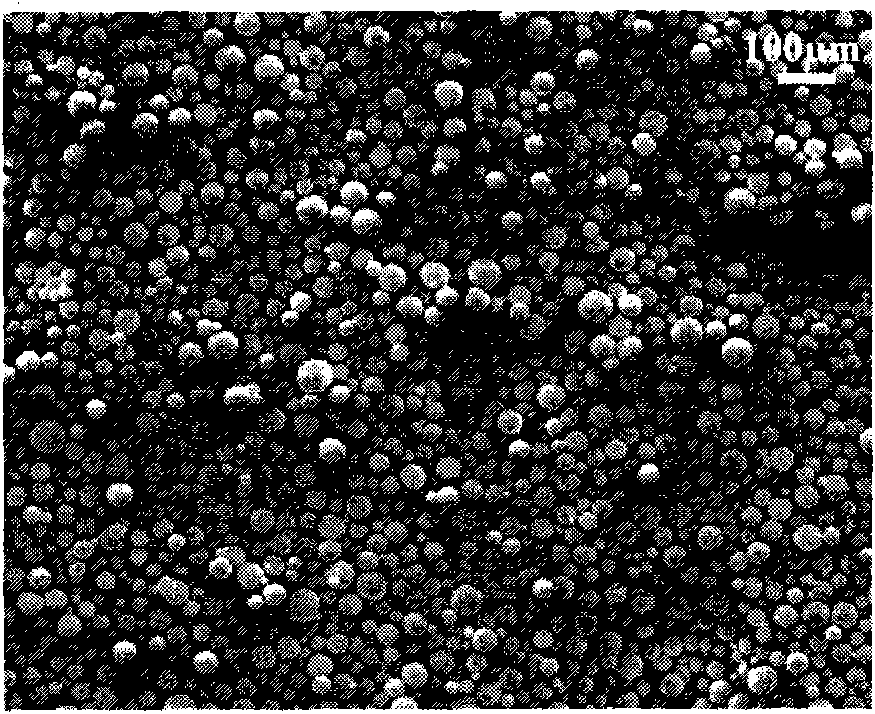

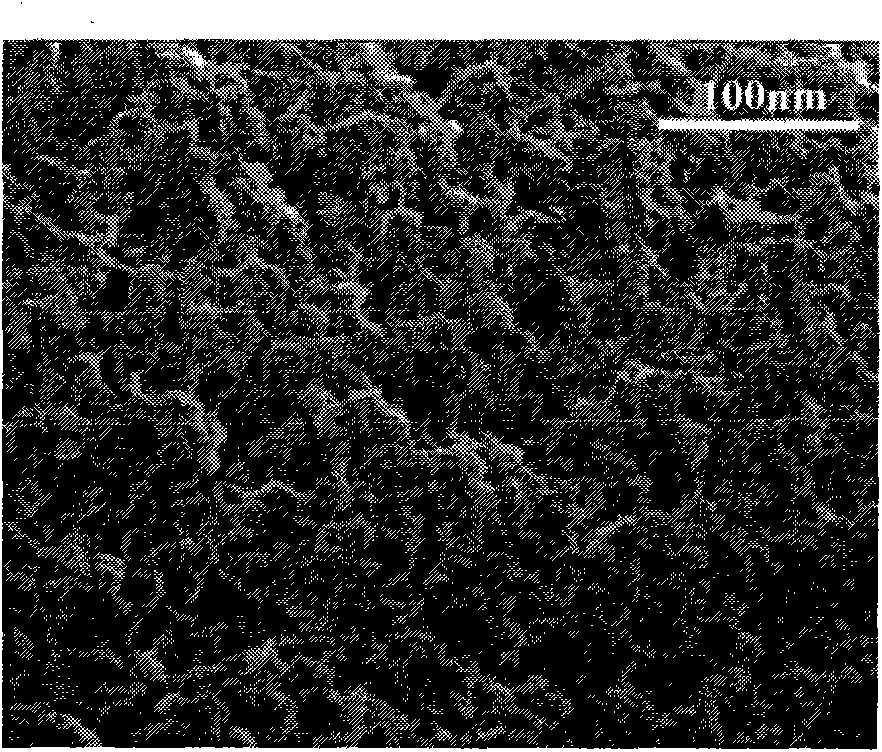

A polyacrylamide and acrylamide technology, applied in the field of materials, can solve the problems of uncontrollable pore size of resin, not very good effect, and not easy to wash out, etc., and achieves uniform and dense pore size, simple preparation method, water absorption and adsorption. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Prepare the water phase

[0037] Add 5.0 g of acrylamide, 0.50 g of ammonium persulfate, and 1.0 g of N,N'-methylenebisacrylamide to 30g of deionized water. Acrylamide and ammonium persulfate, N,N'-methylenebisacrylamide, The mass ratio of deionized water was 1:0.1:0.2:6, and the mixture was stirred until the solid was completely dissolved, and 36.5 g of the water phase was prepared.

[0038] 2. Preparation of oil phase

[0039] Place 90g of cyclohexane in a 250mL three-necked flask equipped with a stirrer, add 0.1g of Span-60, 0.5g of Span-80, and the mass ratio of Span-60 to Span-80 and cyclohexane is 1 : 5:900, stir at room temperature until Span-60 and Span-80 are fully dissolved, and prepare 90.6 g of oil phase.

[0040] 3. Preparation of macroporous polyacrylamide resin

[0041] Add 2 g of N,N' dimethylformamide to the 36g aqueous phase, mix well, the mass ratio of N,N' dimethylformamide to the aqueous phase is 1:18, under nitrogen protection, drip with cons...

Embodiment 2

[0056] In step 1 of preparing the water phase in this example, 5.0 g of acrylamide, 0.30 g of ammonium persulfate, 0.5 g of N,N'-methylenebisacrylamide were added to 15 g of deionized water, acrylamide and ammonium persulfate, The mass ratio of N,N'-methylenebisacrylamide and deionized water was 1:0.06:0.1:3, and the mixture was stirred until the solid was completely dissolved, and 20.8 g of the water phase was prepared. In step 3 of preparing macroporous polyacrylamide resin, add 2.0 g of N,N'-dimethylformamide to 20 g of water phase, mix well, and the mass ratio of N,N'-dimethylformamide to water phase Under nitrogen protection, the mixture of N,N'-dimethylformamide and aqueous phase was added dropwise with a constant pressure dropping funnel at a rate of 10 drops / min, and the stirring speed was 250 rpm. In the 40 g oil phase of , the mass ratio of the water phase to the oil phase was 1:2, the temperature was raised to 70° C., and the reaction was performed at a constant tem...

Embodiment 3

[0058] In step 1 of preparing the water phase in this example, 5.0 g of acrylamide, 0.8 g of ammonium persulfate, 2.0 g of N,N'-methylenebisacrylamide were added to 35 g of deionized water, acrylamide and ammonium persulfate, The mass ratio of N,N'-methylenebisacrylamide and deionized water was 1:0.16:0.4:7, and the mixture was stirred until the solid was completely dissolved, and 42.8 g of the water phase was prepared. In step 3 of preparing macroporous polyacrylamide resin, add 1.0 g of N,N'-dimethylformamide to 40 g of water phase, mix well, and the mass ratio of N,N'-dimethylformamide to water phase Under the protection of nitrogen, the mixture of N,N'-dimethylformamide and aqueous phase was added dropwise with a constant pressure dropping funnel at a dropping rate of 10 drops / min, and the stirring speed was 250 rpm. In the 160 g oil phase of 1, the mass ratio of the water phase to the oil phase is 1:4, the temperature is raised to 70° C., and the reaction is performed at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com