Duct single screw aircraft based on Magnus effect

A technology of aircraft and propeller, which is applied in the field of aircraft, can solve problems such as poor safety, complex structure, and difficult control of flight movements, and achieve the effects of improving safety, high flight efficiency, and improving the influence of uncertain air turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

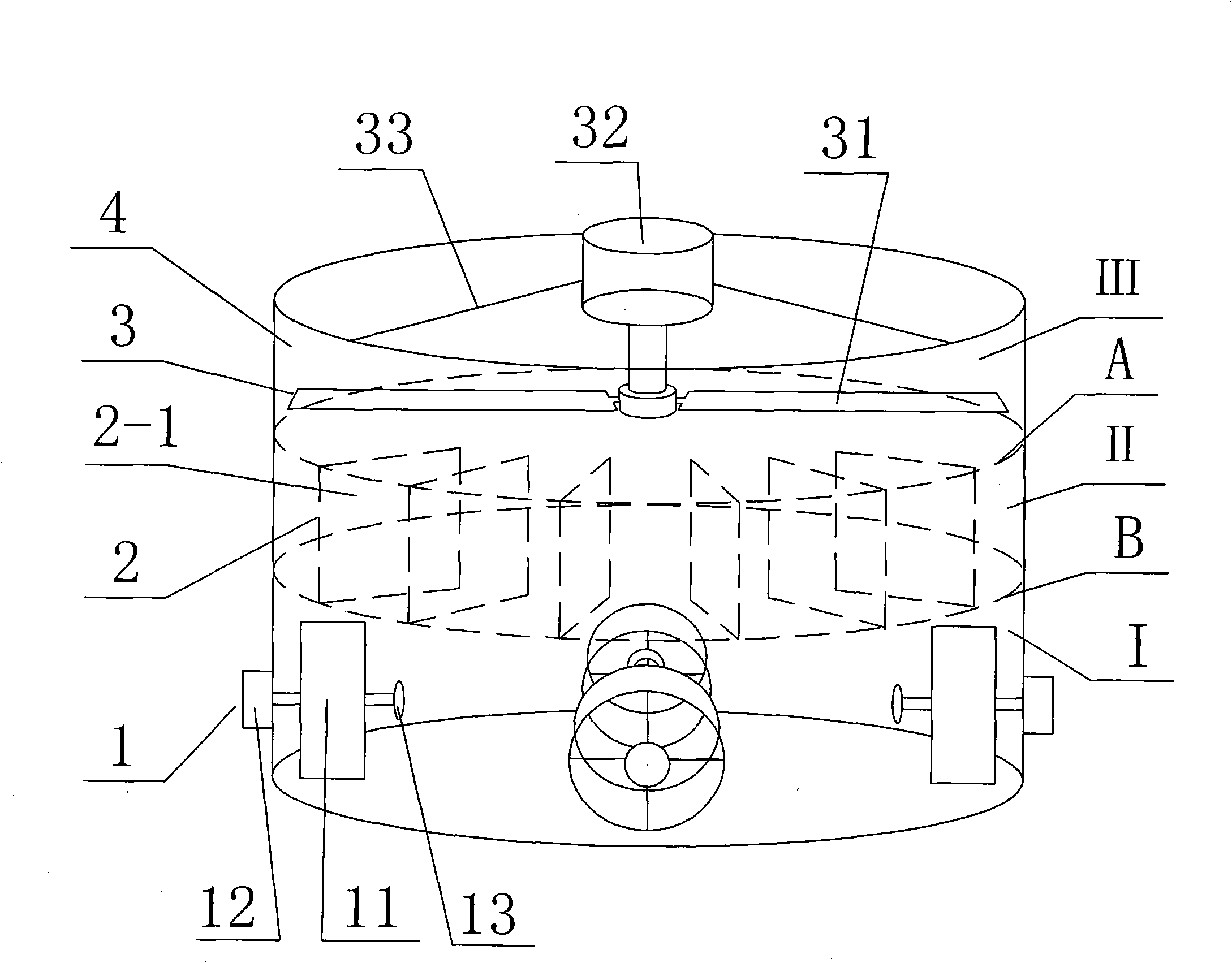

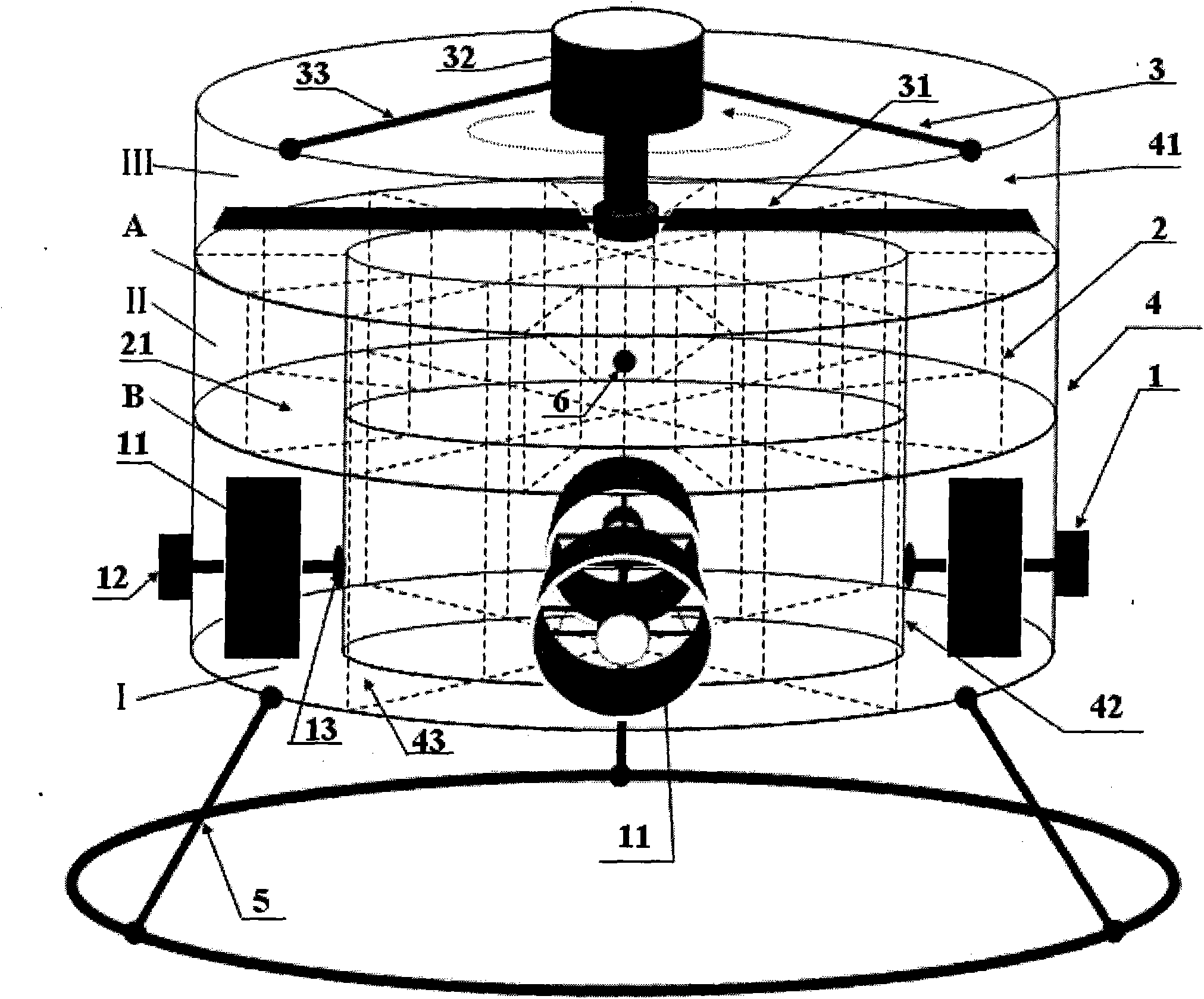

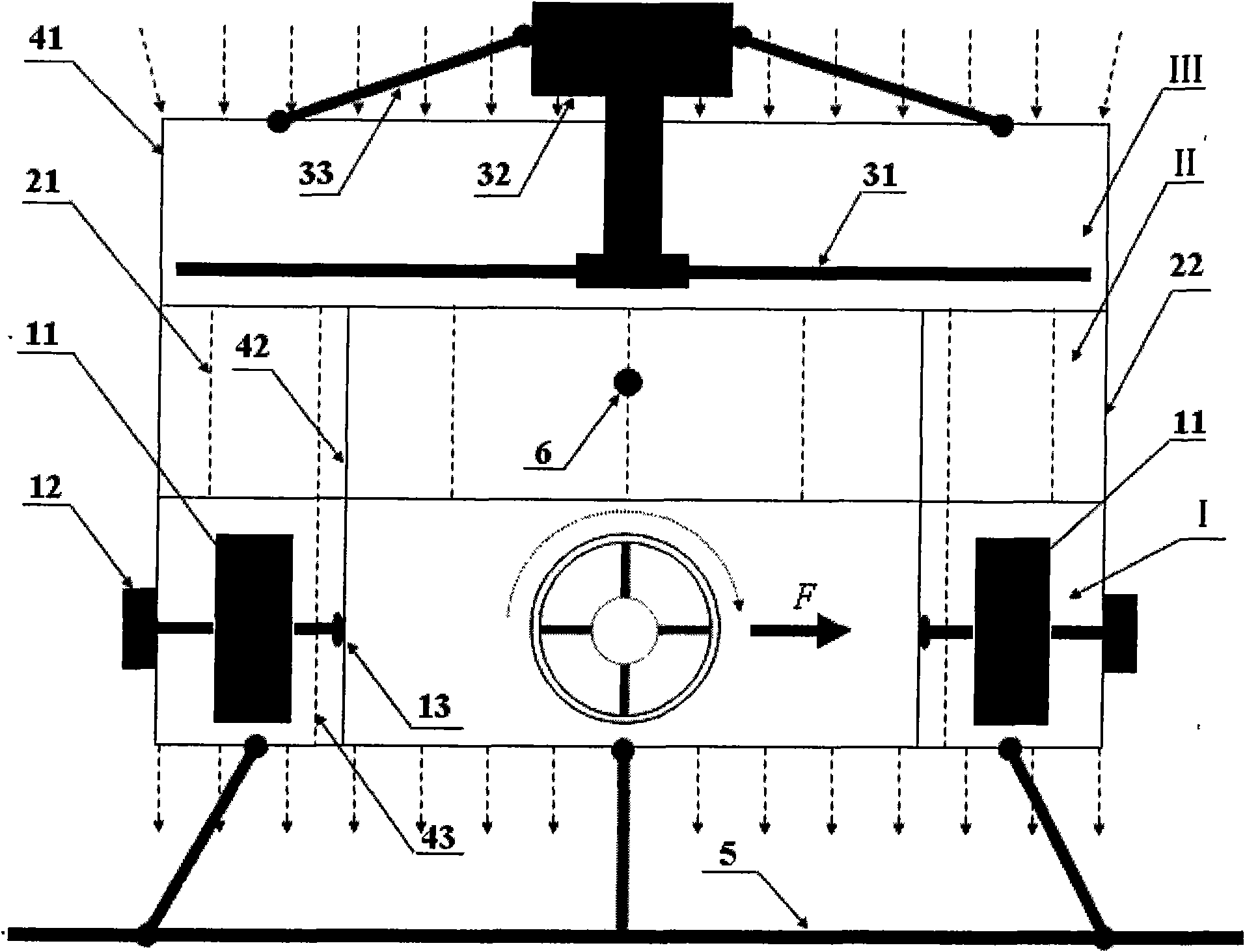

[0018] Specific implementation one: as Figures 1 to 10 As shown, the ducted single-propeller aircraft based on the Magnus effect described in this embodiment includes a steering gear device 1, an airflow adjustment device 2, a power device 3 and an aircraft housing 4; the aircraft housing 4 includes an outer circle Cylinder 41, the steering gear device 1, the air flow adjustment device 2 and the power device 3 are arranged from bottom to top and are centrally installed on the outer cylinder 41 in the axial direction (ie the steering gear device 1, the airflow adjustment device 2 and the power device 3). The centerline of the device 3 coincides with the axis of the outer cylinder 41);

[0019] The steering gear device 1 is composed of four steering gear units, and each steering gear unit includes a hollow wheel 11 and a motor 12; The core wheels 11 are all placed in the inner cavity of the outer cylinder 41, and the four motors 12 are installed on the outer side wall of the o...

specific Embodiment approach 2

[0023] Specific implementation two: as Figures 1 to 4 As shown, the power device 3 in this embodiment is composed of a propeller 31 , a power source 32 and a frame 33 , the power source 32 is fixed on the upper end of the outer cylinder 41 through the frame 33 , and the propeller 31 is installed on the drive of the power source 32 . On the shaft, the drive shaft of the power source 32 drives the propeller 31 to rotate, and the axis of the drive shaft of the power source 32 coincides with the axis of the outer cylinder 41 . The end position of the drive shaft (rotation shaft) of the power source 32 is directly above the total mass center point 6 of the aircraft to ensure flight attitude stability. The propeller is fixed at the end of the rotating shaft. Other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation three: as Figures 1 to 4 As shown, the aircraft housing 4 in this embodiment further includes an inner cylinder 42, the inner cylinder 42 is coaxially arranged in the inner cavity of the outer cylinder 41, and the inner cylinder 42 is located below the power device 3, The lower end surface of the inner cylinder 42 is flush with the lower end surface of the outer cylinder 41 ; the plurality of grid plates 21 are arranged in the annular area between the inner cylinder 42 and the outer cylinder 41 . The provision of the inner cylinder 42 further ensures that the helical air flow is converted into a vertical jet air flow. Other compositions and connection relationships are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com